SECTION5: MAINTENANCE

,_ WARNING: Before

inspecting, cleaningor

servicing the machine,shut off

engine, wait for all moving

parts to cometo a complete

stop, disconnect sparkplug

wire and move wire awayfrom

spark plug. Removeignition

key onelectric start models.

Failureto follow these

instructions can result in

serious personalinjury or

property damage.

MAINTENANCESCHEDULE

PROCEDURE NOTES

Chockmotor oil level 2, 3

Cleanengine 2, 7

Checkdrive belt tension 1,4

Checknuts and bolts 1,4

Change motor oil 1,4, 6

Lubricate tiller 4

Service foam pre-cleanerair filter 7

Service paper air filter 7

Checkgear oil level intransmission 1, 5

Checktines for wear 5

Checkair pressure in tires 5

Service spark plug 7

NOTES

1- After first 2 hours of break-in operation.

2 - Before each use.

3 - Every5 operating hours.

4 - Every 10operating hours.

5 - Every30 operating hours.

6 - Changemore frequently in dusty or dirty

conditions.

7 - SeeEngineOwner's Manual forservice

recommendations.

8 - Whichever time interval occurs first.

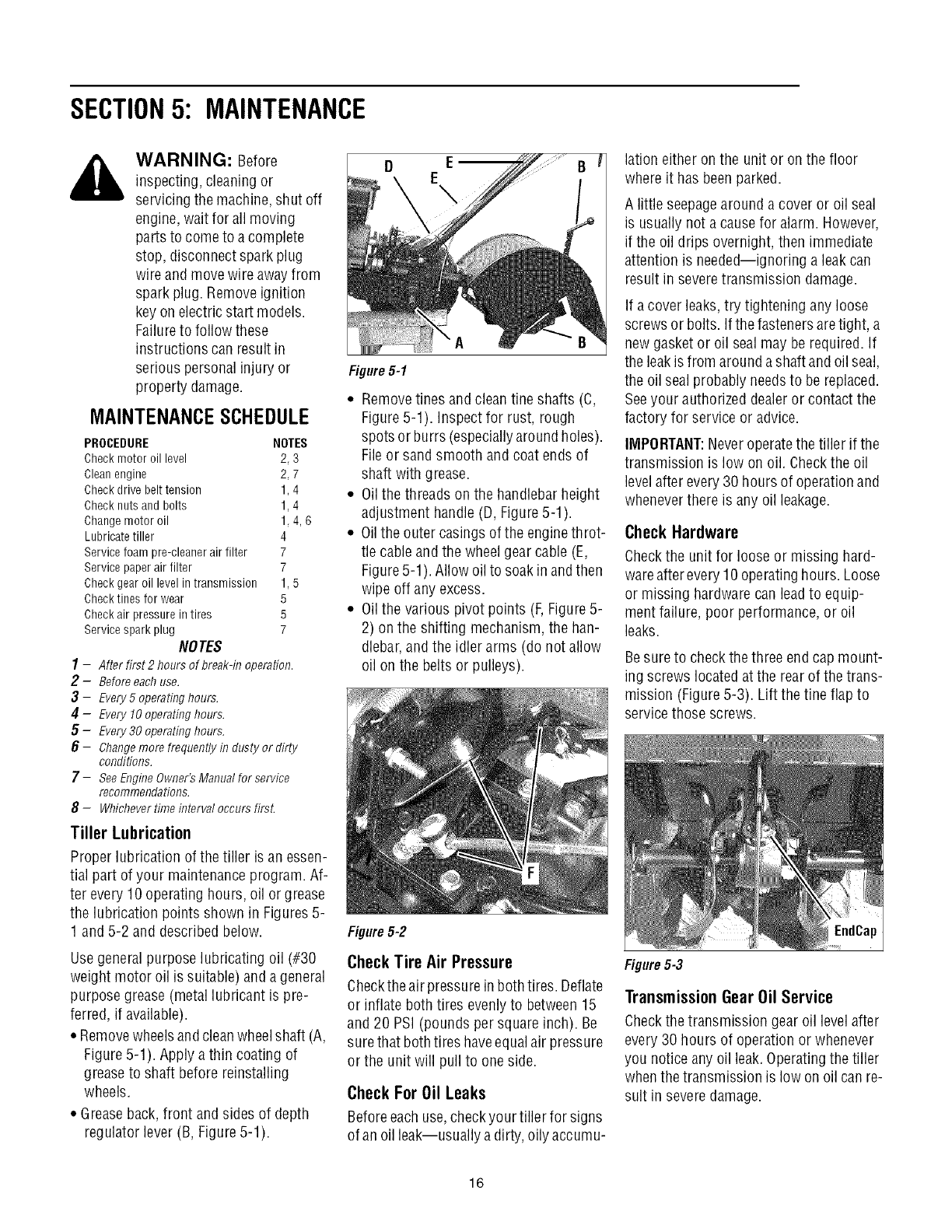

Tiller Lubrication

Proper lubrication of the tiller is an essen-

tial part of your maintenanceprogram. Af-

ter every 10operating hours, oil or grease

the lubrication points shown in Figures5-

1 and 5-2 and described below.

Usegeneral purpose lubricating oil (#30

weight motor oil is suitable) and a general

purpose grease (metal lubricant is pre-

ferred, if available).

• Removewheelsandcleanwheelshaft (A,

Figure 5-1). Apply a thin coating of

greaseto shaft before reinstalling

wheels.

• Greaseback, front and sides of depth

regulator lever (B, Figure5-1).

D L

E

Figure5-1

• Removetines and clean tine shafts (C,

Figure 5-1). Inspect for rust, rough

spots or burrs (especiallyaroundholes).

File or sand smooth and coat ends of

shaft with grease.

• Oil the threads on the handlebarheight

adjustment handle(D, Figure5-1).

• Oilthe outer casings of theenginethrot-

tle cable andthe wheel gearcable (E,

Figure5-1). Allow oil to soak inandthen

wipe off any excess.

• Oil the various pivot points (F,Figure 5-

2) on the shifting mechanism, the han-

dlebar,and the idler arms (do not allow

oil on the belts or pulleys).

Figure5-2

Check Tire Air Pressure

Checktheair pressure inboth tires. Deflate

or inflate both tires evenlyto between 15

and 20 PSi (pounds per square inch). Be

sure that bothtires haveequalair pressure

or the unit will pull to one side.

Check For Oil Leaks

Beforeeach use,checkyour tiller for signs

of an oil leak--usually adirty, oily accumu-

lation either on the unit or onthe floor

where it has been parked.

A little seepagearound a cover or oil seal

is usually not a causefor alarm. However,

if the oil drips overnight,then immediate

attention is needed--ignoring a leak can

result in severetransmission damage.

If a cover leaks,try tightening any loose

screws or bolts. If thefastenersaretight, a

new gasket or oil seal may be required. If

the leakis from arounda shaftand oil seal,

the oil sealprobably needsto be replaced.

Seeyour authorized dealeror contact the

factory for service or advice.

IMPORTANT:Neveroperatethetiller if the

transmission is low on oil. Checkthe oil

level after every30 hours of operation and

wheneverthere is any oil leakage.

CheckHardware

Checkthe unit for loose or missing hard-

wareafter every10 operatinghours. Loose

or missing hardwarecan leadto equip-

ment failure, poor performance, or oil

leaks.

Besure to check the three end capmount-

ing screws locatedat the rear of thetrans-

mission (Figure 5-3). Lift the tine flap to

service those screws.

Figure5-3

EndCap

Transmission Gear Oil Service

Checkthe transmission gear oil level after

every 30 hours of operation or whenever

you notice anyoil leak.Operatingthe tiller

when thetransmission is lowon oil canre-

sult in severe damage.

16