4. Withtheforwardclutchcable (N,

Figure2-4) on the insideofhandlebar,

position the handlebarendson the

outside of the two mounting tabs (M,

Figure2-3) on the transmission top

cover.

NOTE:Thecurved handlebarheight

adjustment bracketappearsasshown in

C,Figure2-3 for non-electric start units.

Forelectric start units, the bracket is loos-

enedand moved to one side.

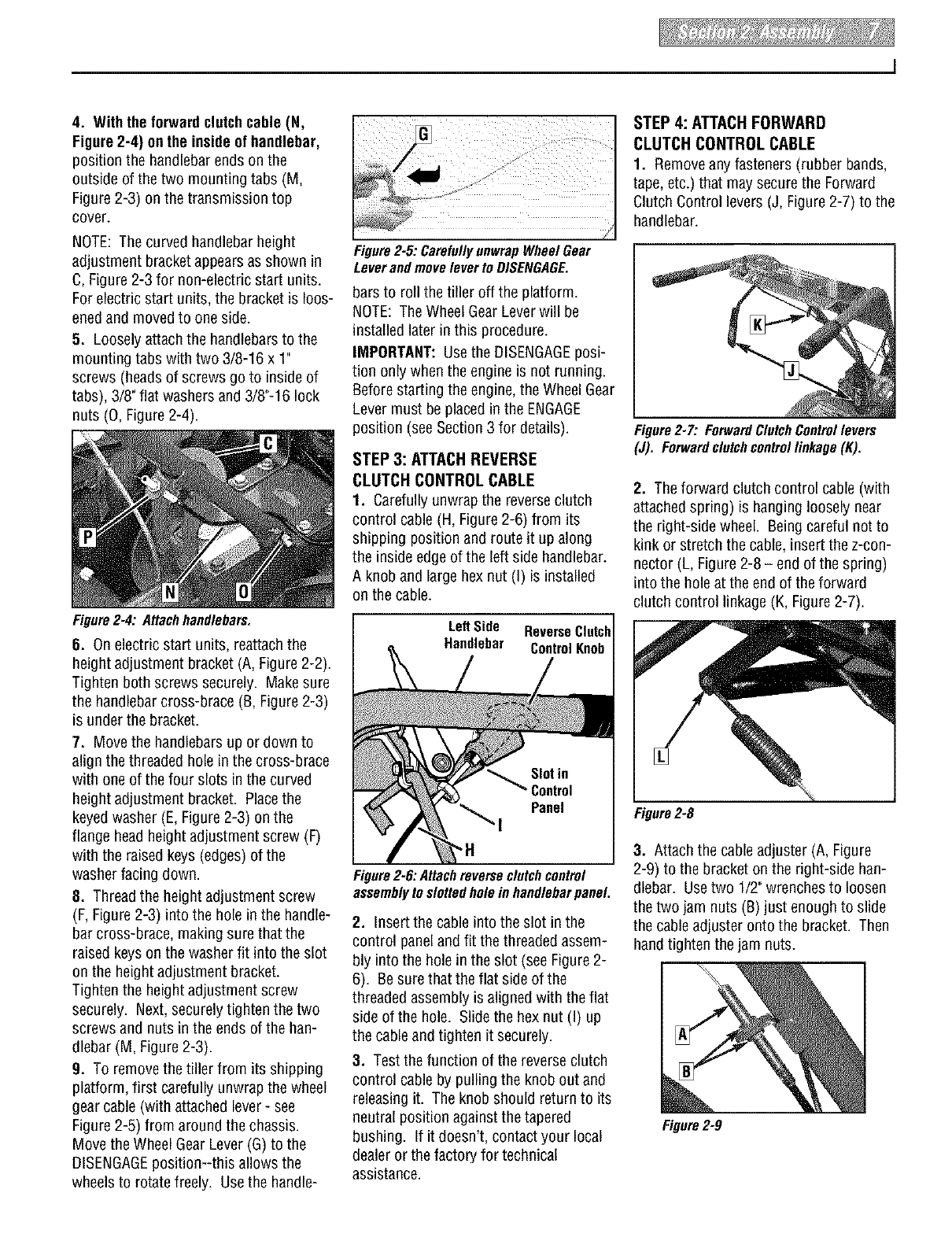

5. Loosely attachthe handlebarsto the

mounting tabs with two 3/8-16 x 1"

screws (headsof screws go to insideof

tabs), 3/8" flat washersand 3/8"-16 lock

nuts (O,Figure2-4).

Figure24: Attachhandlebars.

6. On electricstart units, reattachthe

heightadjustment bracket (A,Figure2-2).

Tighten both screws securely. Makesure

the handlebarcross-brace (B, Figure2-3)

is under the bracket.

7. Move the handlebarsup or down to

align the threadedhole in the cross-brace

with one of thefour slots in the curved

heightadjustment bracket. Placethe

keyedwasher (E,Figure2-3) on the

flange head heightadjustment screw (F)

with the raisedkeys (edges)of the

washer facing down.

8. Threadthe heightadjustment screw

(F, Figure 2-3) into the hole in the handle-

bar cross-brace, making surethat the

raisedkeyson thewasher fit into the slot

on the height adjustment bracket.

Tighten the heightadjustment screw

securely. Next, securelytighten the two

screwsand nuts in the ends ofthe han-

dlebar (M, Figure2-3).

9. To removethe tiller from its shipping

platform, first carefully unwrapthe wheel

gearcable (with attachedlever- see

Figure2-5) from around the chassis.

Move theWheel Gear Lever(G) to the

DISENGAGEposition--this allows the

wheels to rotatefreely. Usethe handle-

g

#

Figure25: CarefullyunwrapWheelGear

LeverandmovelevertoDISENGAGE.

barsto roll the tiller off the platform.

NOTE:TheWheelGearLeverwill be

installed later in this procedure.

IMPORTANT: Usethe DISENGAGEposi-

tion only when the engineis not running.

Beforestarting the engine,theWheel Gear

Levermust beplaced in the ENGAGE

position (seeSection 3 for details).

STEP3: ATTACHREVERSE

CLUTCH CONTROL CABLE

1. Carefullyunwrap the reverseclutch

control cable(H, Figure2-6) from its

shipping position and route it upalong

the insideedge ofthe left side handlebar.

A knoband large hexnut (I) is installed

on the cable.

LeftSide ReverseClutch

Handlebar ControlKnob

Figure2-6."Attachreverseclutchcontrol

assemblytoslottedholeinhandlebarpanel.

2. Insert the cableinto the slot in the

control paneland fit the threadedassem-

bly into the hole in theslot (seeFigure2-

6). Besurethat the flat sideof the

threaded assemblyis aligned with the flat

side ofthe hole. Slidethe hex nut (I) up

the cableand tighten it securely.

3. Testthe function of the reverseclutch

control cableby pulling the knob out and

releasingit. Theknob should returnto its

neutral position against the tapered

bushing. If it doesn't, contact your local

dealer or thefactory for technical

assistance.

STEP 4: ATTACHFORWARD

CLUTCH CONTROLCABLE

1. Removeanyfasteners (rubber bands,

tape, etc.)that may secure the Forward

Clutch Control levers (J, Figure2-7) to the

handlebar.

I

Figure2-7: ForwardClutchControllevers

(J). Forwardclutchcontrollinkage(K).

2. Theforward clutch control cable(with

attachedspring) is hanging loosely near

the right-side wheel. Beingcareful not to

kink or stretch the cable, insert the z-con-

nector (L, Figure2-8 - end of the spring)

into the hole at the end of theforward

clutch control linkage(K, Figure2-7).

Figure2-8

3. Attach thecableadjuster (A, Figure

2-9) to the bracket on the right-side han-

dlebar. Usetwo 1/2"wrenchesto loosen

thetwo jam nuts (B)just enough to slide

the cableadjuster onto the bracket. Then

hand tighten the jam nuts.

Figure2-9