L

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug. J

Remove the key from the keyswitch on units soequipped. J

Failure to follow these instructionscan result in serious personal injury or propertydamage.

Incorrect cable adjustment could cause

the wheels and tines to rotate unexpect-

edly. Follow adjustment procedures

carefully. Failure to do so could result

in personalinjuryorpropertydamage.

CheckingForwardBelt Tension

1. Beforechecking, shut off engine,allow

the engine and muffler to cool down, dis-

connectthe spark plug wire, removethe

ignition key on electricstart models.

2. Thecoiled part of the forward clutch

spring (E, Figure5-10) measures2" in

lengthwhen the Forward ClutchControl

leversare not pulledup. Pull either

ForwardClutch Control Lever up against

the handlebarand measurethe length of

the coil on the forward clutch spring.

Tension iscorrect if the length of the

extendedcoil is 2-1/2" (seeFigure5-11).

Theforward clutch control cable needs

adjustment if the extended lengthof the

coil is not 2-1/2". SeeAdjusting the

Forward Clutch Beltfor a procedure.

Adjustingthe ForwardClutchCable

Dothis procedure if theforward clutch

spring measurement is not correct (see

CheckingForward Belt Tension).

1. Beforeadjusting the belt, shut off

engine,allow the engineand muffler to

cool down, disconnect the spark plug

wire, and removethe ignition key on elec-

tric start models.

A

Tension.

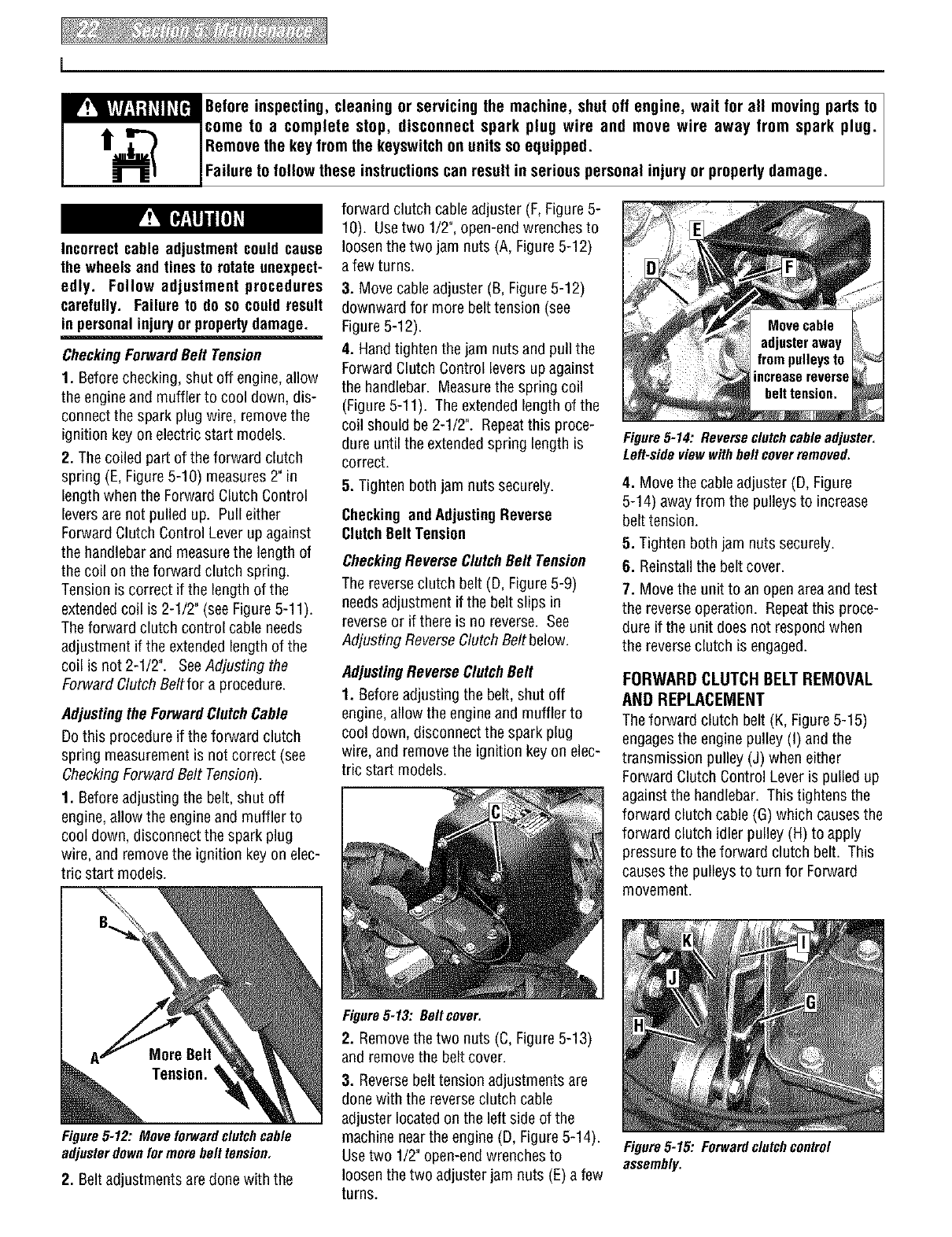

Figure5-12: Moveforwardclutchcable

adjuster downformorebelttension,

2. Beltadjustments aredone with the

forward clutch cableadjuster (F,Figure5-

10). Usetwo 1/2", open-end wrenchesto

loosenthetwo jam nuts (A, Figure5-12)

afew turns.

3. Move cableadjuster (B, Figure5-12)

downward for more belttension (see

Figure5-12).

4. Handtighten the jam nuts and pull the

Forward Clutch Control leversup against

the handlebar. Measurethe spring coil

(Figure5-11). Theextendedlength of the

coil should be 2-1/2". Repeatthis proce-

dure until theextendedspring length is

correct.

5. Tighten bothjam nuts securely.

CheckingandAdjustingReverse

ClutchBeltTension

CheckingReverseClutchBelt Tension

Thereverseclutch belt (D, Figure5-9)

needsadjustment if the belt slips in

reverseor if there is no reverse. See

Adjusting ReverseClutchBelt below.

AdjustingReverseClutchBelt

1. Beforeadjusting the belt, shut off

engine,allow theengine and muffler to

cool down, disconnect the spark plug

wire, and remove the ignition keyon elec-

tric start models.

Figure5-13: Beltcover.

2. Removethe two nuts (C, Figure5-13)

and removethe beltcover.

3. Reversebelttension adjustments are

donewith the reverseclutch cable

adjuster located on the left sideof the

machine nearthe engine (D, Figure5-14).

Usetwo 1/2"open-endwrenches to

loosenthe two adjuster jam nuts (E) a few

turns.

Figure5-14: Reverse clutchcableadjuster.

Left-sideview withbeltcover removed.

4. Move thecable adjuster (D, Figure

5-14) awayfrom the pulleys to increase

belt tension.

5. Tighten both jam nuts securely.

6. Reinstallthe belt cover.

7. Move the unit to an open areaand test

the reverseoperation. Repeatthis proce-

dure if the unit does not respondwhen

the reverseclutch is engaged.

FORWARD CLUTCH BELTREMOVAL

AND REPLACEMENT

Theforward clutch belt (K,Figure5-15)

engagesthe engine pulley (I) and the

transmission pulley (J) wheneither

Forward Clutch Control Leveris pulled up

against the handlebar. This tightens the

forward clutch cable (G)which causesthe

forward clutch idler pulley (H) to apply

pressure to theforward clutch belt. This

causesthe pulleysto turn for Forward

movement.

Figure5-15: Forwardclutchcontrol

assembly.