Assembly

To prevent personal injury or property

damage,do not startthe engineuntil all

assembly steps are complete and you

havereadand understandthesafetyand

operatinginstructionsin this Manual.

INTRODUCTION

Carefullyfollow these assembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in its entirety before beginning assembly.

INSPECTUNIT

Inspectthe unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protectyour rights, put your

claim in writing and maila copy to the

carrier within 15 days after the unit has

been delivered.Contact usat the factory if

you needassistance in this matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeanycardboard insertsand

packaging materialfrom the carton.

Removeany staplesfrom the bottom of

the carton and removethe carton.

2. Cutthe large,plastictie strap that

securesthetransmission tube to theship-

ping pallet. Leavethe handlebarson top

of the tiller to avoid damaginganycables.

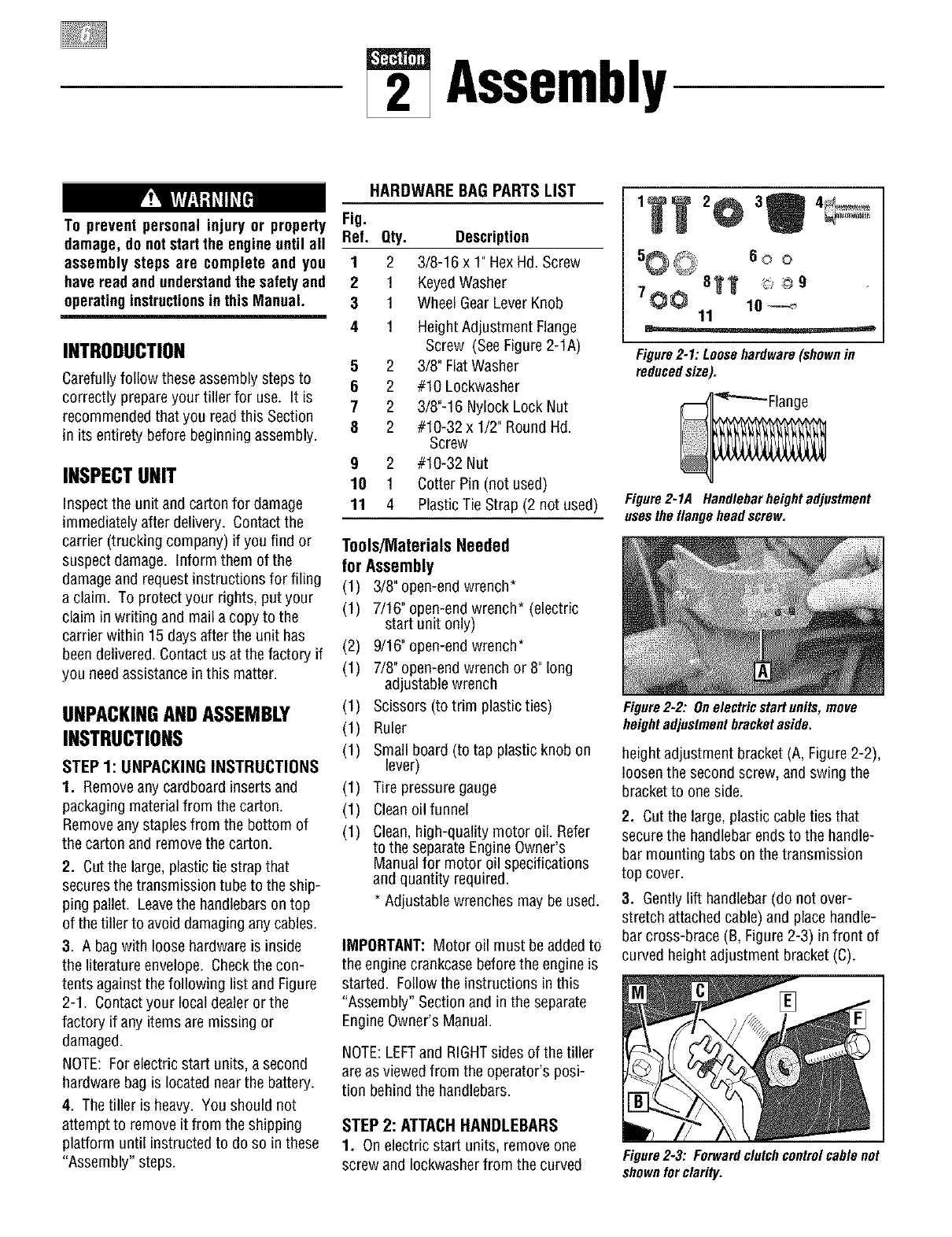

3. A bag with loose hardwareis inside

the literature envelope. Checkthe con-

tents against thefollowing list and Figure

2-1. Contactyour local dealeror the

factory if any items are missing or

damaged.

NOTE: Forelectric start units, a second

hardware bag is located nearthe battery.

4. Thetiller is heavy. You should not

attempt to remove it from the shipping

platform until instructed to do so in these

"Assembly" steps.

HARDWARE BAG PARTSLIST

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1" HexHd. Screw

2 1 KeyedWasher

3 1 WheelGearLeverKnob

4 1 Height Adjustment Flange

Screw (SeeFigure2-1A)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" RoundHd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 PlasticTie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8"open-end wrench*

(1) 7/16" open-endwrench* (electric

start unit only)

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench or 8" long

adjustablewrench

(1) Scissors (to trim plasticties)

(1) Ruler

(1) Small board (to tap plasticknob on

lever)

(1) Tire pressuregauge

(1) Cleanoilfunnel

(1) Clean,high-quality motor oil. Refer

to the separateEngineOwner's

Manualfor motor oil specifications

and quantity required.

* Adjustable wrenches may be used.

IMPORTANT:Motor oil must beadded to

the enginecrankcase beforethe engine is

started. Followthe instructions inthis

"Assembly" Sectionand in the separate

EngineOwner's Manual.

NOTE:LEFTand RIGHTsidesof the tiller

areas viewedfrom the operator's posi-

tion behindthe handlebars.

STEP 2: ATTACHHANDLEBARS

1. On electric start units, remove one

screw and Iockwasherfrom the curved

'T

600

7_ 8_' _ _9

10 _.

11

Figure2-1:Loosehardware(shownin

reducedsize).

Figure2.1A Hand/ebarheightadjustment

usestheflangeheadscrew.

Figure2-2: Onelectricstartunits,move

heightadjustmentbracketaside.

heightadjustment bracket (A, Figure2-2),

loosenthe second screw, and swing the

bracketto oneside.

2. Cut the large,plastic cableties that

securethe handlebarendsto the handle-

bar mounting tabs on thetransmission

top cover.

3. Gently lift handlebar(do not over-

stretch attachedcable)and placehandle-

bar cross-brace (B, Figure2-3) in front of

curved height adjustment bracket (C).

Figure2-3: Forwardclutchcontrolcablenot

shownforclarity.