Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove the key from the keyswitchon units so equipped.

Failure to follow these instructionscan result in serious personal injury or property damage.

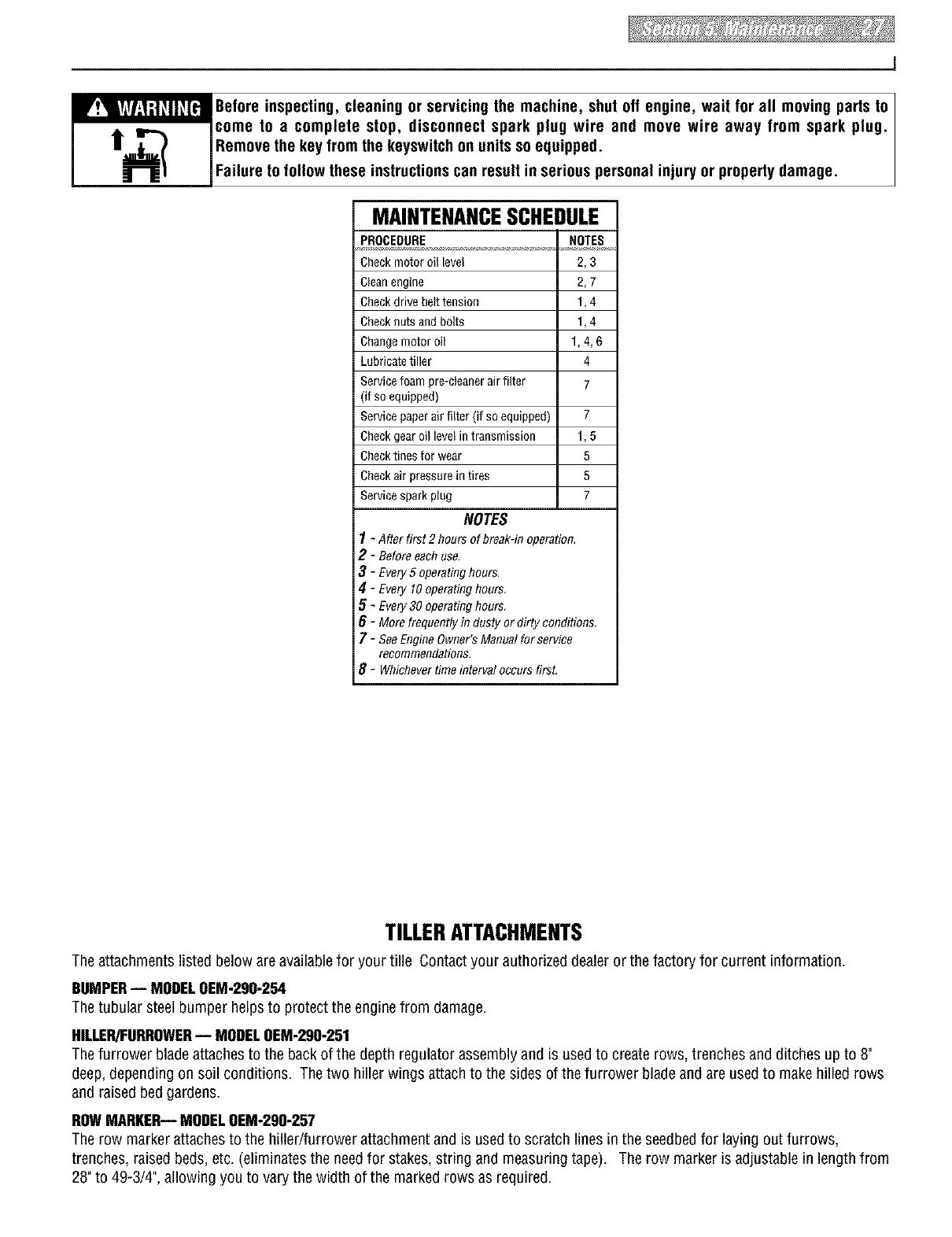

MAINTENANCESCHEDULE

PROCEDURE NOTES

Check motor oil level 2, 3

C)eanengine 2, 7

Check drive belt tension 1,4

Check nuts and bolts 1,4

Changemotoroi( 1,4,6

Lubricatetiller 4

Servicefoampre-cleanerairfilter 7

(if so equipped)

ServicepaperairfUter(ifso equipped) 7

Check gear oil levelin transmission 1,5

Checktines for wear 5

Checkairpressureintires 5

Servicespark p)ug 7

NOTES

1 - Atier first 2 hours of break-in operation.

2 - Before each use.

3 - Every5 operatinghours,

4 - Every10operatinghours,

5 - Every30 operating hours,

6 - More frequently in dusty or dirty conditions,

7 - SeeEngineOwner'sManualforservice

recommendations,

8 - Whichevertimeintervaloccursfirst,

TILLERATTACHMENTS

Theattachments listed beloware availablefor your tille Contact your authorizeddealer or the factory for current information.

BUMPER-- MODEL0EM-290-254

Thetubular steel bumper helpsto protectthe enginefrom damage.

HILLER/FURROWER-- MODEL0EM-290-251

Thefurrower bladeattachesto the backof the depth regulator assemblyand is usedto create rows, trenchesand ditches upto 8"

deep,depending on soil conditions. Thetwo hiller wings attachto the sidesofthe furrower bladeand are usedto makehilled rows

and raisedbedgardens.

ROWMARKER--MODEL0EM-290-257

The row marker attachesto the hiller/furrower attachment and is usedto scratch linesin the seedbedfor layingout furrows,

trenches, raised beds, etc.(eliminates the needfor stakes, string and measuring tape). Therow markeris adjustable in lengthfrom

28"to 49-3/4", allowing you to varythewidth of the marked rows as required.