Sefore inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove the key from the keyswitchon units so equipped.

Failure to follow these instructionscan result in serious personal injury or property damage.

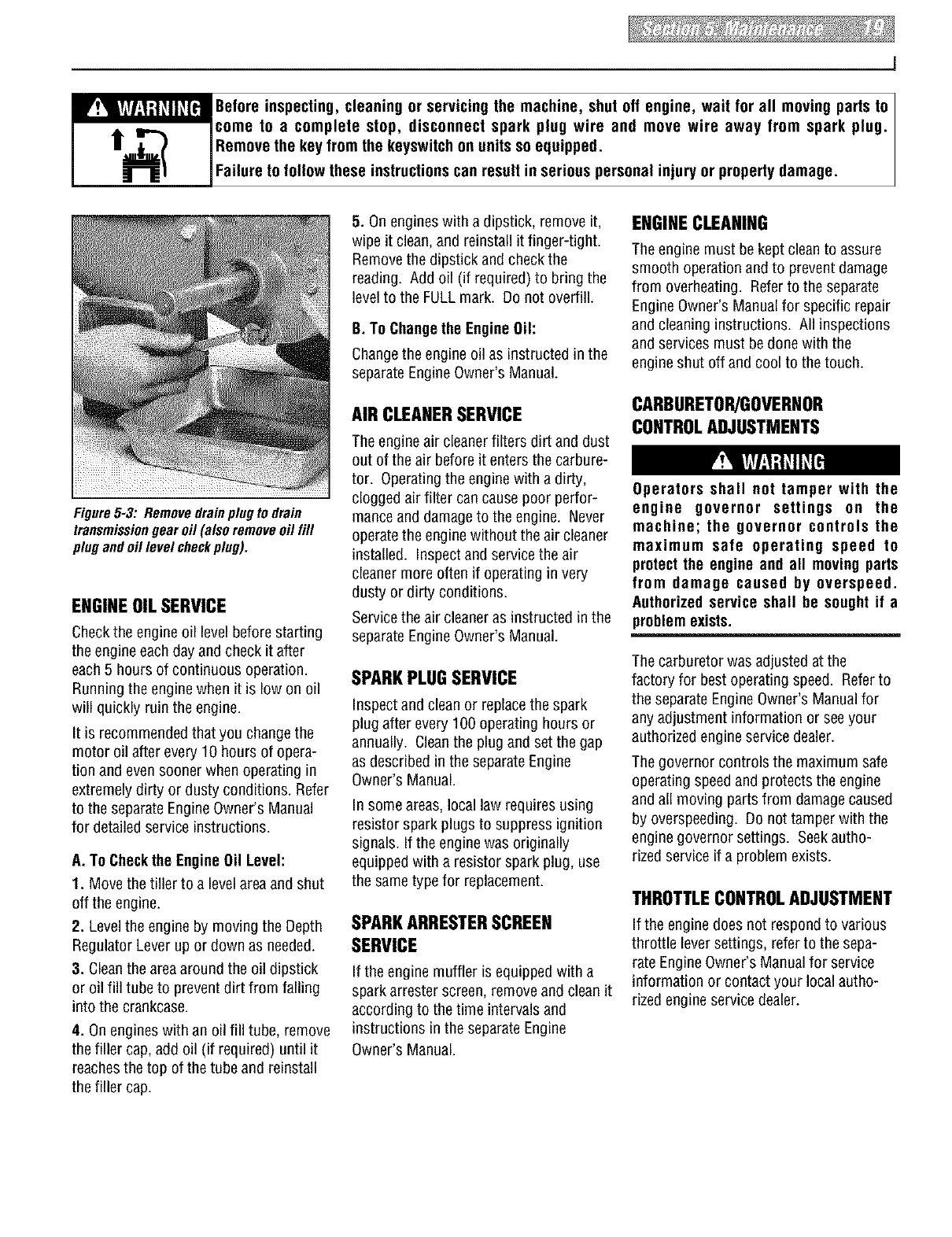

Figure5-3: Removedrainplug todrain

transmissiongear oil (alsoremoveoil fill

plugand oil level checkplug).

ENGINEOILSERVICE

Checktheengine oil levelbeforestarting

the engineeachday and checkit after

each5 hours of continuous operation.

Runningthe enginewhen it is low on oil

will quickly ruin the engine.

It is recommendedthat you changethe

motor oil after every 10 hours of opera-

tion and evensoonerwhen operating in

extremely dirty or dusty conditions. Refer

to the separateEngineOwner's Manual

for detailedservice instructions.

A. To ChecktheEngineOil Level:

1. Move the tiller to a levelareaand shut

off the engine.

2. Levelthe engine by moving the Depth

RegulatorLever up or down asneeded.

3. Cleanthe areaaround the oil dipstick

or oil fill tube to prevent dirt from falling

into the crankcase.

4. On engineswith an oil fill tube, remove

the filler cap, add oil (if required) until it

reachesthe top ofthe tube and reinstall

the filler cap.

5. On engineswith a dipstick, remove it,

wipe it clean,and reinstall it finger-tight.

Removethe dipstick andcheck the

reading. Add oil (if required) to bring the

levelto the FULLmark. Do not overfill.

B. To ChangetheEngineOil:

Changethe engine oil as instructed in the

separateEngineOwner's Manual.

AIR CLEANERSERVICE

Theengineair cleanerfilters dirt and dust

out of theair before it enters the carbure-

tor. Operatingthe engine with a dirty,

clogged air filter cancausepoor perfor-

mance and damageto the engine. Never

operatethe enginewithout the air cleaner

installed. Inspect and servicethe air

cleanermore often if operating in very

dusty or dirty conditions.

Servicethe air cleaneras instructed in the

separateEngineOwner's Manual.

SPARKPLUGSERVICE

Inspectand clean or replacethe spark

plug after every 100 operating hours or

annually. Cleanthe plug and set the gap

as described in the separateEngine

Owner's Manual.

In someareas, locallaw requiresusing

resistor spark plugs to suppressignition

signals. If the enginewas originally

equipped with a resistor sparkplug, use

the sametype for replacement.

SPARK ARRESTER SCREEN

SERVICE

If the engine muffler is equippedwith a

spark arrester screen, removeand clean it

according to thetime intervals and

instructions in the separateEngine

Owner's Manual.

ENGINECLEANING

Theengine must be kept cleanto assure

smooth operationand to preventdamage

from overheating. Referto the separate

EngineOwner's Manualfor specific repair

and cleaninginstructions. All inspections

and services must be done with the

engine shut off and cool to thetouch.

CARBURETOR/GOVERNOR

CONTROLADJUSTMENTS

Operators shall not tamper with the

engine governor settings on the

machine; the governor controls the

maximum safe operating speed to

protectthe engine and all movingparts

from damage caused by overspeed.

Authorized service shall be sought if a

problemexists.

Thecarburetor was adjusted at the

factory for best operatingspeed. Refer to

the separateEngineOwner's Manualfor

anyadjustment information or seeyour

authorizedengine service dealer.

Thegovernor controls the maximum safe

operating speedand protects the engine

and all moving parts from damagecaused

by overspeeding. Donot tamper with the

engine governor settings. Seekautho-

rized serviceif a problemexists.

THROTTLE CONTROL ADJUSTMENT

If the enginedoes not respond to various

throttle leversettings, referto the sepa-

rate EngineOwner's Manualfor service

information or contact your localautho-

rized engineservicedealer.