Two Stage Snowthrower Drive Systems Manual 3 - 3

Traction Drive Systems

6. The axle can now be removed from the chassis.

Inspect the gear, the roll pin, and the areas where

the bearings contact the axle for damage or

severe wear. Remove the thrust washers from

either end of the axle. The purpose of the roll pin

and thrust washers is to limit the side to side

movement of the axle.

7. Disconnect the two clevis pins on the shift linkage

rods.

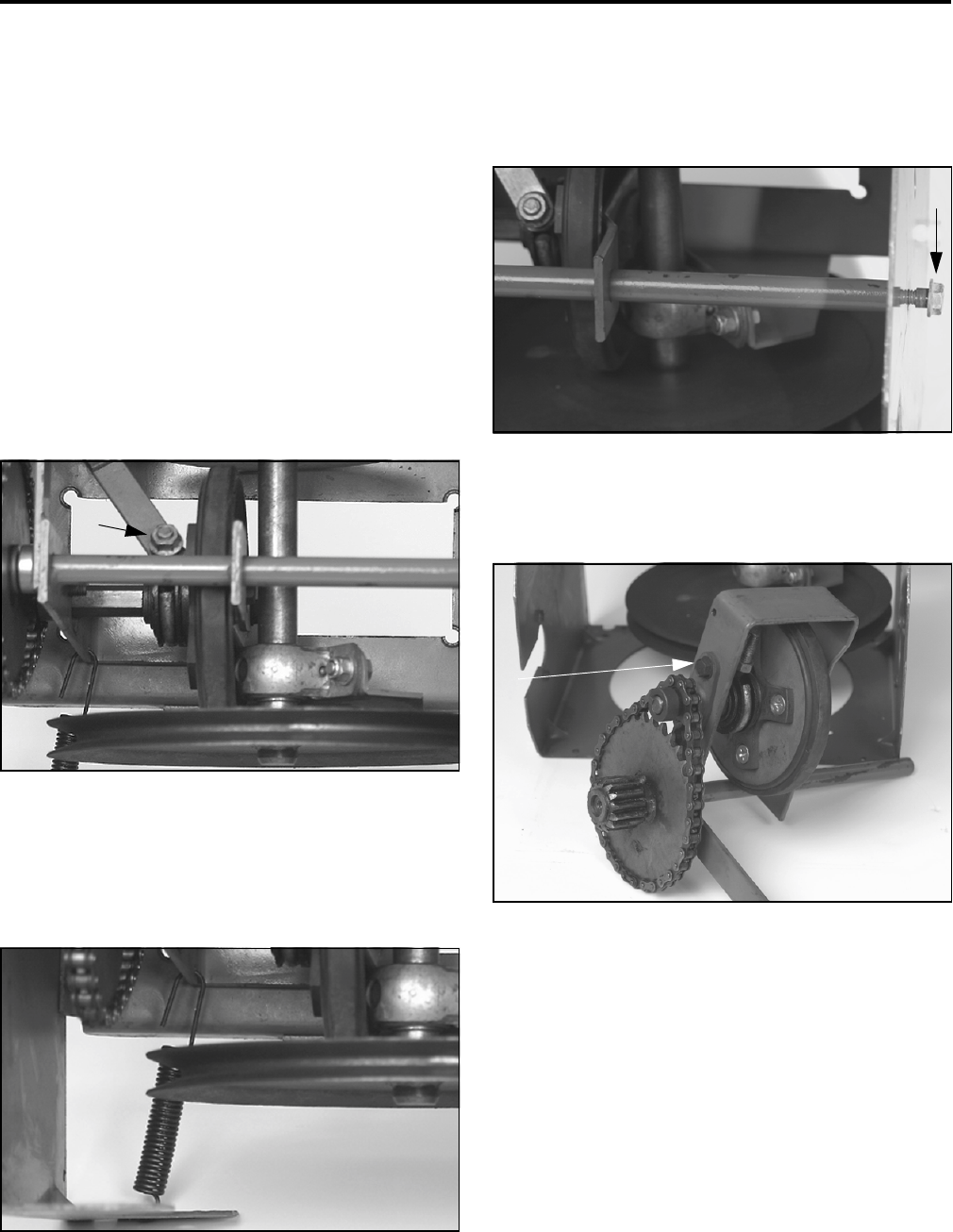

8. Next to the friction wheel is a large eyebolt, which

is connected to the shift linkage (Figure 74).

Remove the flange nut and washer from the end

of the eyebolt. Note the location and type of

washers. You should be able to slip the linkage off

of the eyebolt. If not, loosen the shoulder screw

that the linkage pivots on.

Figure 74

2768-32A

9. There is a spring connected between the left front

corner of the pivot shaft (that contains the friction

wheel) forward to a tab on the chassis. Unhook

one end of this spring (Figure 75).

Figure 75

2768-32B

10. The pivot shaft, which contains the friction wheel,

is retained by two shoulder bolts. They pass

through the side plate, into the ends of the shaft.

Remove these two bolts and the pivot assembly

will slide out of the chassis (Figure 76).

Figure 76

2768-033

11. To disassemble the pivot assembly, proceed as

follows (Figure 77):

Figure 77

2768-036

A. The drive chain contains a master link.

Separate that and remove the chain.

B. To remove the friction wheel, remove four cap

screws securing the hex shaft bearings. Slide

the bearings off the ends of the hex shaft.

C. The hex shaft can now be removed from the

pivot assembly.

D. If the friction wheel is to be replaced, remove

the four screws and lock nuts connecting it to

the traction drive hub.

1

1

.

Fl

ange nu

t/

eye

b

o

lt

1

1

.

Sh

ou

ld

er

b

o

lt

1

1

.

H

ex s

h

a

ft

b

ear

i

ng