Two Stage Snowthrower Drive Systems Manual 1 - 7

Auger Gearbox Service

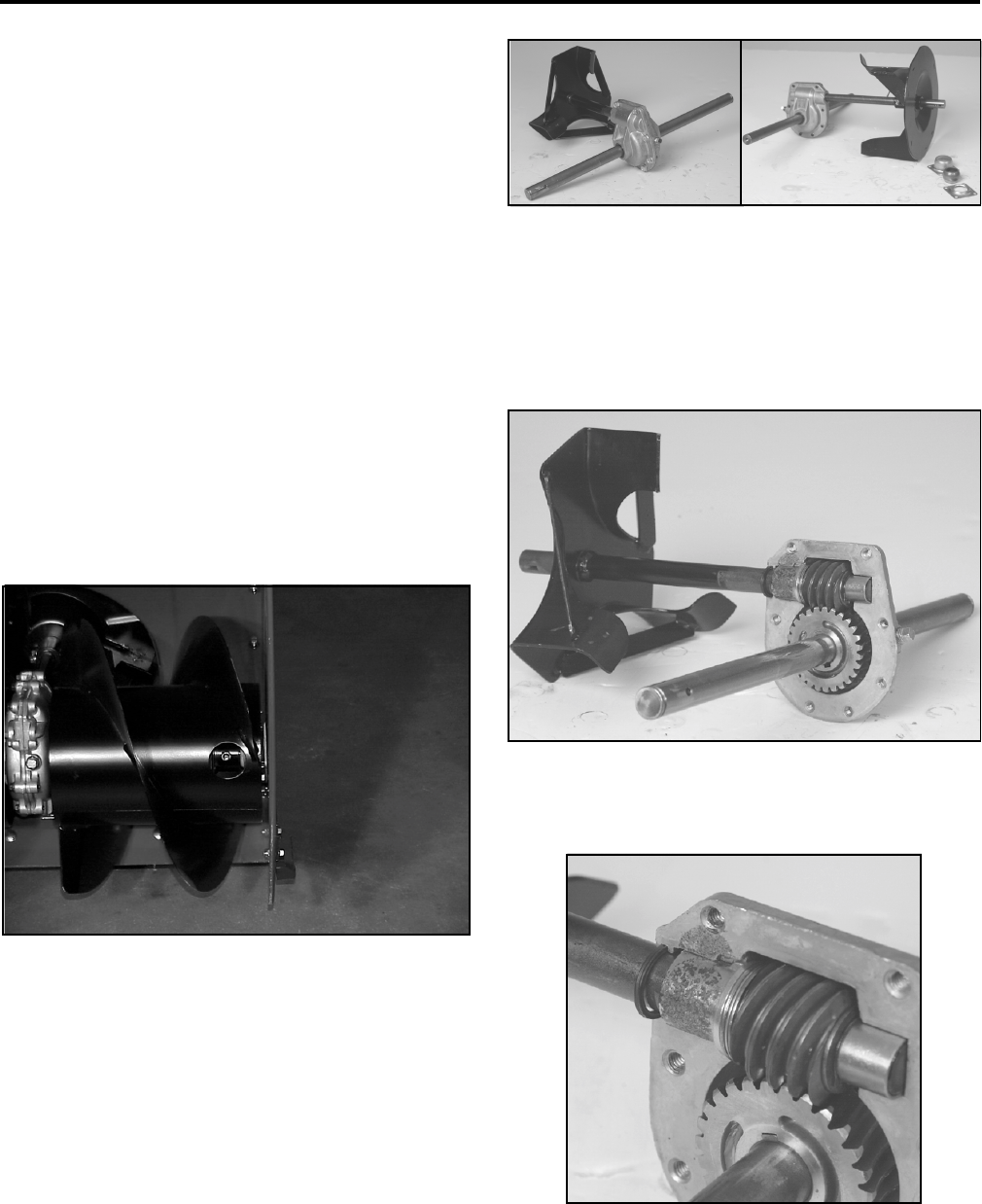

AUGER GEARBOX DISASSEMBLY /

SERVICE

Once the auger gearbox assembly is removed from the

housing the repair process is the same for all models.

The only variables are what type of lubricant is used

(see the chart on Introduction page 1), whether the

impeller is removable from the shaft (on some models

the impeller is welded to the shaft) and how the

gearbox case halves are sealed.

Auger gearbox disassembly:

1. With the gearbox assembly removed from the

housing the first step is to slide the bearings off

the output shafts. (Model 38080 & 38065, also

slide the scraper off).

2. All models use a cap screw, lock nut, and spacer

to connect the auger to the shaft (Figure 22).

Remove the cap screw, nut and spacer and slide

both augers from the shaft.

Figure 22

MVC-533

3. Some models have the impeller welded to the

impeller shaft. Others use a combination of bolts,

set screws, and a key. If you see bolt(s) through

the impeller hub, remove them. Some may have

set screws, which only require being loosened.

The models with the setscrews also have a key

between the hub and shaft. Once the visible

retainers are removed, slide the impeller away

from the gearbox, the key will be uncovered.

Remove the key (Figure 23).

Figure 23

2773-055/2773-066

4. Remove the 8 or 9 self-tapping screws that hold

the gearbox halves together. Note: On a model

that uses 90 weight gear oil, you may want to

place the gearbox over a pan when the screws are

removed. Then separate the gearbox halves

(Figure 24).

Figure 24

2773-060

5. The impeller shaft can now be removed

(Figure 25).

Figure 25

2773-061