5-4-8

CYLINDER HEAD

(1)

Clean carbon and gum deposits from the valves, seats, ports and guides. Inspect the valves, valve

(2) Replace valves that are badly burned, pitted or warped.

(3)

When installing the valves in the cylinder head, oil the valve stems and insert them into the valve

guide.

Then place the cylinder head

on

a flat

table,

install the valve springs, spring retainers

and

collet

valves.

(4)

Valve guides should be replaced when the valve stem clearance exceeds specifications (See

"SERVICE

DATA").

Draw the valve guides out and press the new guides in.

Refer to"SERV1CE

DATA"for

clearance specifications.

After replacing the valves and guides, lap valves

in

place until a uniform ring shows around the face

of the valve. Clean valves and wash cylinder head thoroughly.

Tighten four flange bolts evenly in three steps by the following tightening torque:

Cylinder head

M8

X

65

mm flange bolt

-

-

4

PCS.

(EH12-2, 17-2)

seats and valve guides.

(5)

Install cylinder head to cylinder with new head gasket.

M10

X

75

mm

flange bolt

-

4

pcs.

(EH25-2)

Tightening torque

(EH12-2,

17-2)

1

st

step final step

2nd step

5

Nom

100

kgcm

50

kgwn

23-26

Nm

10

Nom

17-30

ft-lb

7.2

ft-lb

3.6

ft-lb

230-270

kgcm

Tightening torque

(EH25-2)

1

st

step

final

step

2nd step

9.8

Nom

100

kgecrn

33.3-41.2

Nom

19.6

Nom

24.6-30.4

ft*lb

14.5

ft4b

7.2

ft-lb

340-420

kg-cm

200

kgcm

n

54-9

ROCKER

ARMS

AND

PUSH

RODS

(1)

Insert push rods into crankcase.

Put push rod tip in the hollow

of

tappet top.

(2)

Apply oil to the rocker arms and assemble them to the cylinder head using pivot bolt and guide plate.

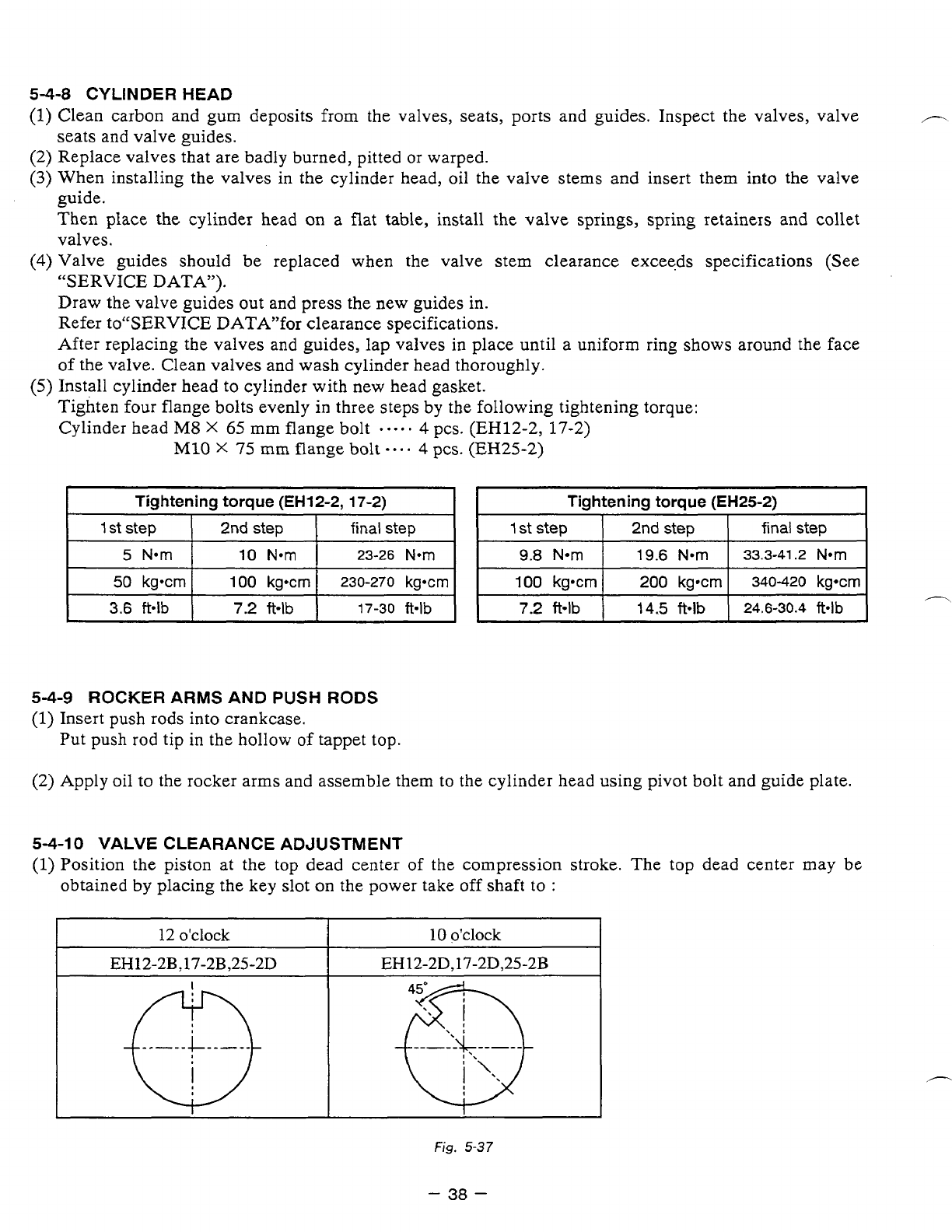

5-4-10

VALVE

CLEARANCE ADJUSTMENT

(1)

Position the piston at the top dead center of the compression stroke. The top dead center may be

obtained by placing the key slot

on

the power take

off

shaft

to

:

I

12

o'clock

I

10 o'clock

I

EH12-2B,17-2B,25-2D

I

EH12-2D,17-2D,25-2B

-

38

-