(2)

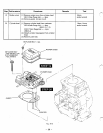

Install the piston and connecting rod assembly

into the cylinder.

Use a piston ring compressor

to

hold

the piston

rings.

Place

“MAG”

side of the connecting rod on the

magneto side

of

the crankcase.

[NOTES]

(1)

Apply

enough oil to piston rings, connecting

rod bearings

and

cylinder bore before

assembly.

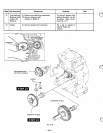

(2)

Set gaps of the piston rings

90

degrees

apart

from each other before assembly.

PISTON RING COMPRESSOR

CONNECTING

ROD

CRANKCASE (FLYWHEEL

SIDE)

Fig.

5-3

1

SECOND

RING

./=<

0

RING

Fig.

5-32

54-4

CONNECTING

ROD

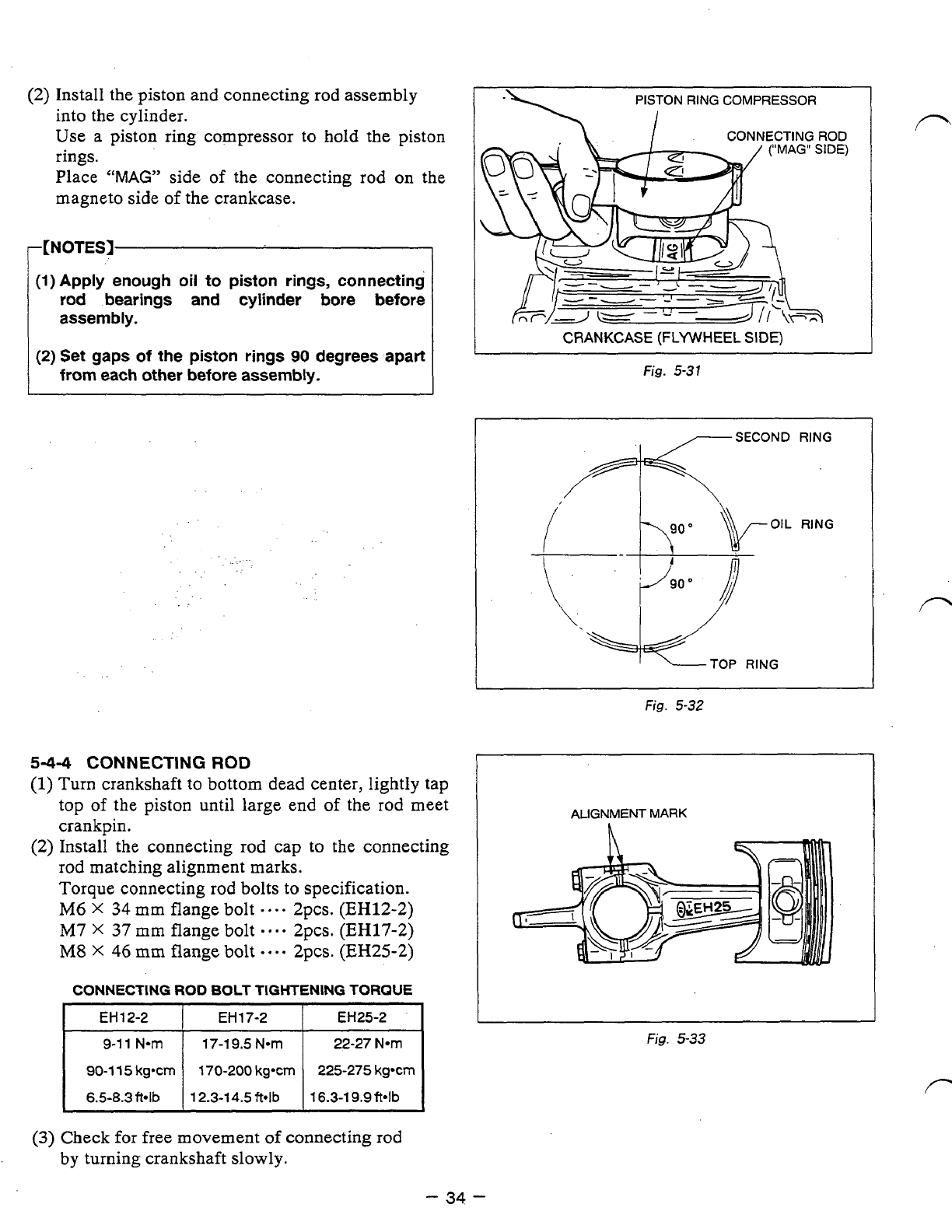

(1)

Turn crankshaft

to

bottom dead center, lightly tap

top

of

the piston until large end

of

the rod meet

crankpin.

(2) Install the connecting rod cap to the connecting

rod

matching alignment marks.

Torque

connecting

rod

bolts

to specification.

M6

X

34

mm

flange bolt 2pcs.

(EH12-2)

M7

X

37

mm

flange bolt

-0..

2pcs.

(EH17-2)

M8

X

46

mm

flange

bolt

2pcs.

(EH25-2)

CONNECTING

ROD

BOLT TIGHTENING TORQUE

I

EH

1

2-2

EH

17-2

EH25-2

1

17-1

9.5

Nom

22-27

N*m

(3)

Check

for

free movement

of

connecting rod

by turning crankshaft slowly.

ALIGNMENT MARK

Fig.

5-33

-

34

-