3.

FEATURES

,

,

1.

The overhead valve design offers

a

compactness, light weight and ideal combustion characteristics

2.

An

optimum lubrication and better tilted operation thanks to upright cylinder design.

3.

A crossflow arrangement

of

intake and exhaust ports ensures stable performance under high ambient

temperature.

4.

The automatic decompressiom system lightens

the

recoil pull force by

40%

comparing to the

conventional

SV

engines.

5.

An easy operation thanks to integrated engine control system.

Improved throttle mechanism

is

adopted for easy starting.

6.

Combustion and mechanical noises have been analyzed acoustically and improved for better tonal

quality and lower engine noise.

7.

Optimally designed reciprocating parts reduce the vibration level of the engine.

EH25-2

engine

equips single through-balancer shaft as an option.

resulting in more power from Iess fuel and prolonged engine life.

4.

GENERAL DESCRIPTION

OF

ENGINE COMPONENTS

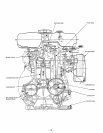

4-1

CYLINDER

AND

CRANKCASE

The cylinder and crankcase

is

single piece aluminum

diecasting. The cylinder liner, made of special cast

iron,

is

molded into the aluminum casting.

The crankcase has a mounting surface. on the output

shaft side, where the main bearing cover is attached.

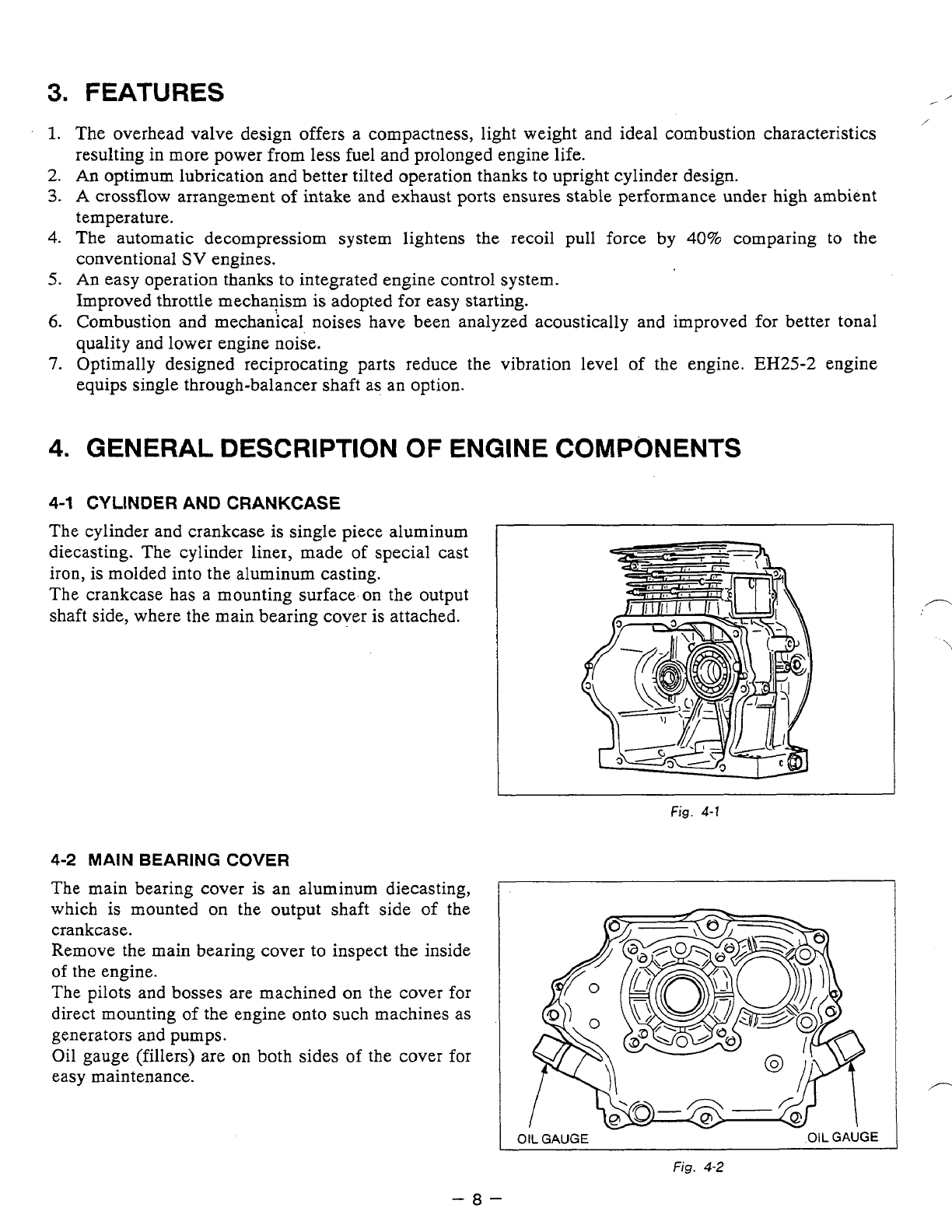

4-2

MAIN

BEARING

COVER

The main bearing cover

is

an aluminum diecasting,

which

is

mounted on the output shaft side of the

crankcase.

Remove the main bearing cover to inspect the inside

of

the engine.

The pilots and bosses are machined on the cover for

direct mounting of the engine onto such machines

as

generators and pumps.

Oil gauge (fillers) are on both sides of the cover for

easy maintenance.

Fig.

4-1

OIL GAUGE

OIL

GAUGE

/"-

\

/"

Fig.

4-2

-8-