5.

Fuel

passage

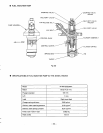

From the plunger pump fuel is sent through the highpres-

sure pipe

1

to the fuel passage

2.

Then, at the nozzle body

3,

it is pressurized up till 195 kg/cm2 and it lifts up the needle

valve

4

for

0.18

mm, and is sprayed into the combustion

chamber via the jet hole

5.

An

excess fuel which lubricated the inside of the nozzle and

nozzle holder returns to the fuel tank via the needle valve

+

nozzle spring

6

+

overflow pipe

7

+

fuel tank,

(See Fig.

63

.)

6.

Inspection and maintenance

1

2

7

6

3

4

5

Fig.

63

Fuel spraying condition

of

the nozzle and the state of pressure at starting injection are quite influential to the engine mal-

function, insufficient output, increase

of

noise and exhaust smoke. Use

of

improper fuel and contaminated fuel is one of the

main courses of the nozzle trouble. Therefore, exert good care for managment

of

fuel.

As

the nozzle is one of the very pre-

cisely processed parts, utmost care and attention must be paid when inspecting and checking.

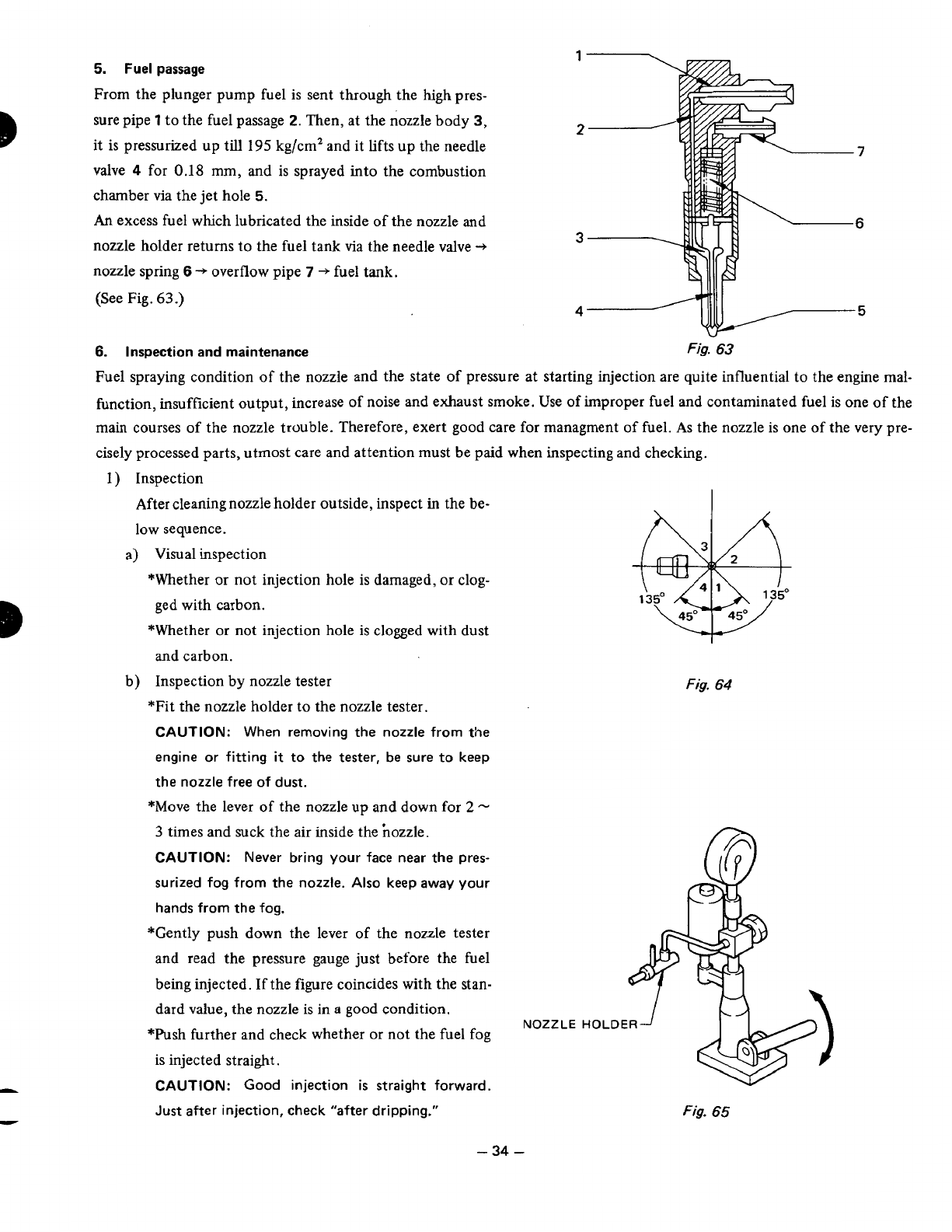

1)

Inspection

After cleaning nozzle holder outside, inspect

in

the be-

low sequence.

a) Visual inspection

*Whether or not injection hole is damaged, or clog-

ged with carbon.

*Whether or not injection hole is clogged with dust

and carbon.

b)

Inspection by nozzle tester

*Fit the nozzle holder to the nozzle tester.

CAUTION: When removing the nozzle from

the

engine or fitting

it

to the tester, be sure

to

keep

the nozzle free of dust.

*Move the lever of the nozzle up and down for

2

-

3

times and suck the air inside the hozzle.

CAUTION: Never bring your face near the pres-

surized

fog

from the

nozzle.

Also

keep away your

hands from the fog.

*Gently push down the lever of the nozzle tester

and read the pressure gauge just before the fuel

being injected. If the figure coincides with the stan-

dard value, the nozzle is in a good condition,

*Push

further and check whether or not the fuel fog

is injected straight.

CAUTION: Good injection

is

straight forward.

Fig.

64

NOZZLE

Just

after

injection, check "after dripping."

Fig.

65

-

34

-