4-15

COMBUSTION

SYSTEM

For

lower fuel consumption and easy starting of the engine,

the direct injection system is adopted in the combusition

chamber.

4-15-1

FORMING

of

COMBUSTION GAS

and

COMBUS-

TION

/INTAKE

VALVE

INTAKE

PORT

SWIRL

CYLINDER

PISTON

Fig.

13

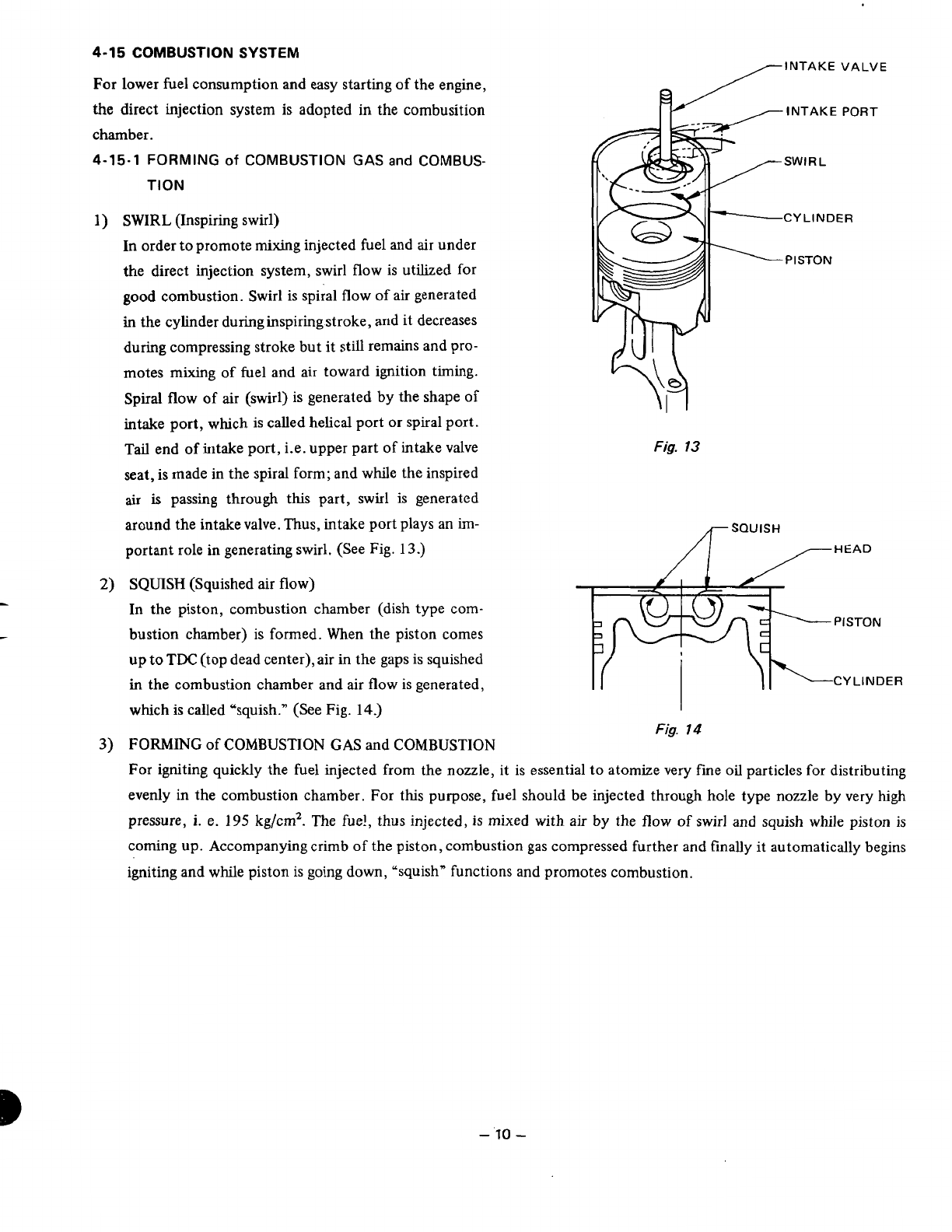

SWIRL

(Inspiring swirl)

In order to promote mixing injected fuel and air under

the direct injection system, swirl flow is utilized for

good

Combustion. Swirl is spiral flow

of

air generated

in

the cylinder during inspiring stroke, and it decreases

during compressing stroke but it still remains and pro-

motes mixing of fuel and

air

toward ignition timing.

Spiral flow

of

air

(swirl)

is generated by the shape of

intake port, which

is

called helical port

or

spiral port.

Tail

end of intake port, i.e. upper part of intake valve

seat, is made in the spiral form; and while the inspired

air

is

passing through this part, swirl

is

generated

around the intake valve. Thus, intake port plays an

im-

portant role in generating

swirl.

(See Fig. 13.)

SQUISH

(Squished air flow)

In the piston, combustion chamber (dish type com-

bustion chamber) is formed. When the piston comes

up to

TDC

(top dead center), air in the gaps is squished

in

the combustion chamber and air flow is generated,

which is called “squish.” (See Fig.

14.)

FORMING

of

COMBUSTION

GAS

and

COMBUSTION

For igniting quickly the fuel injected from the nozzle, it is essential to atomize very fine

oil

particles

for

distributing

evenly in the combustion chamber.

For

ths purpose, fuel should be injected through hole type nozzle by very

high

pressure, i. e.

195

kg/cm2. The fue!, thus injected,

is

mixed with

air

by

the flow of swirl and squish while piston

is

Coming Up. Accompanying crimb

of

the piston, combustion gas compressed further and finally it automatically begins

igniting and while piston is going down, “squish” functions and promotes combustion.

Fig.

14

-

10

-