[4] DISASSEMBLY/ASSEMBLY

[4]-7. Ignition

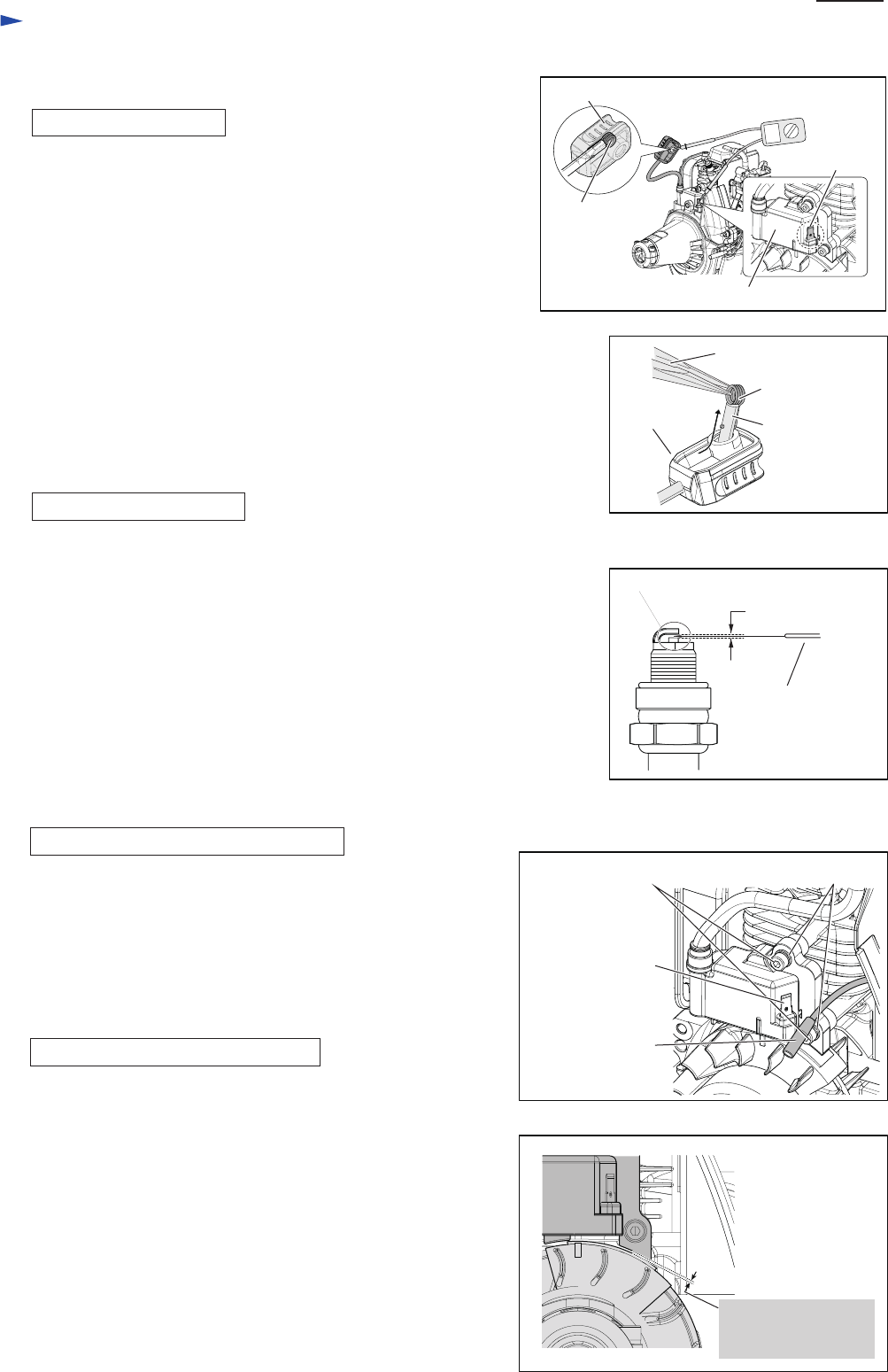

(1) Remove Plug cap from Spark plug and test the continuity

between Plug cap spring in Plug cap and Earth terminal of

Ignition coil.

It is in order when Tester shows 2.0kΩ±0.5kΩ.(Fig. 15)

(2) In case of no continuity or unstable continuity, check the

connection between Plug cap spring and Ignition coil as follows:

(A) Spray the lubricant in Plug cap, then pull out Plug cap spring

together with Ignition cable using Long-nose pliers. (Fig. 16)

(B) In case no connection or inconsistent connection,

check the condition of Plug cap and spring.

Reassemble them or replace them if they are disorder.

(C) Insert the end of Plug cap spring into Ignition cable, then return them

back to the inside of Plug cap carefully so as not to be disconnected.

(D) Check Plug cap and spring again according to the step of (1) to avoid

poor connection causing the poor sparks of Spark plug.

ASSEMBLING OF IGNITION COIL

(1) Insert 0.3mm Feeler gauge of 1R366 in between the

magnet portion of Flywheel and Ignition coil. Tighten M4x20

Hex socket head bolts (2pcs) while keeping Ignition coil

attached to Flywheel through 0.3mm thickness gauge.

Note: Two M4x20 Hex socket head bolts (Fig. 19) are with

threadlocker. Therefore, when re-using them, apply

ThreeBond 1342 or Loctite 242 to the threads.

(2) After setting Ignition coil, remove the thickness gauge, then

turn Flywheel by hand to check if it turns smoothly

without being stuck.

Note: Be sure to insert Spacer on M4x20 Hex socket head bolt

when fastening Ignition coil to Engine. (Fig. 18)

(3) Assemble Cylinder cover to Engine.

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

CHECKING PLUG CAP

(1) Remove Plug cap with Plug cap spring, then remove Spark plug with Box

driver 15-17 (standard equipment).

Note: If the electrodes are wet with Fuel, wipe it away with a cloth and

dry it by air blow.

(2) Clean carbon deposits on Electrodes on Insulator tip with a wire brush.

(3) Do fine adjustment of a gap between Side electrode and Center electrode of

Spark plug by inserting 0.7mm Feeler gauge of 1R366. (Fig. 17)

(4) Mount Plug cap with Plug cap spring on Plug terminal and connect

Screw part of Plug to a metal part of Engine, then pull Starter rope slowly.

The sparks can be seen when starter rope is pulled.

(5) When the sparks can not be seen, follow the procedure of

[CHECKING PLUG CAP] to test the continuity. If it has yet to be solved,

replace Plug and recheck the ignition through the above process.

CHECKING SPARK PLUG

(1) Remove Cylinder cover and cable from Ignition coil terminal.

(2) Loosen M4x20 Hex socket head bolts (2pcs) and remove

Ignition coil from Engine. (Fig. 18)

Note: Do not lose Spacers for heat insulation (2pcs) on the bolts.

DISASSEMBLING OF IGNITION COIL

0.6 up to 0.7mm

Plug cap spring

Plug cap

Ignition cable

Long-nose pliers

Clearance between

Flywheel and

Ignition coil: 0.3mm

Plug cap

Ignition coil

Earth terminal

M4x20 Hex socket

head bolt (2pcs.)

Spacer (2pcs.)

Tab of Ignition

coil to connect

with Cable

Connector

of Cable

Plug cap spring

Repair

P 7/ 14

0.7 mm Feeler

gauge of 1R366

Electrode