[4] DISASSEMBLY/ASSEMBLY

[4]-14. Engine block (cont.)

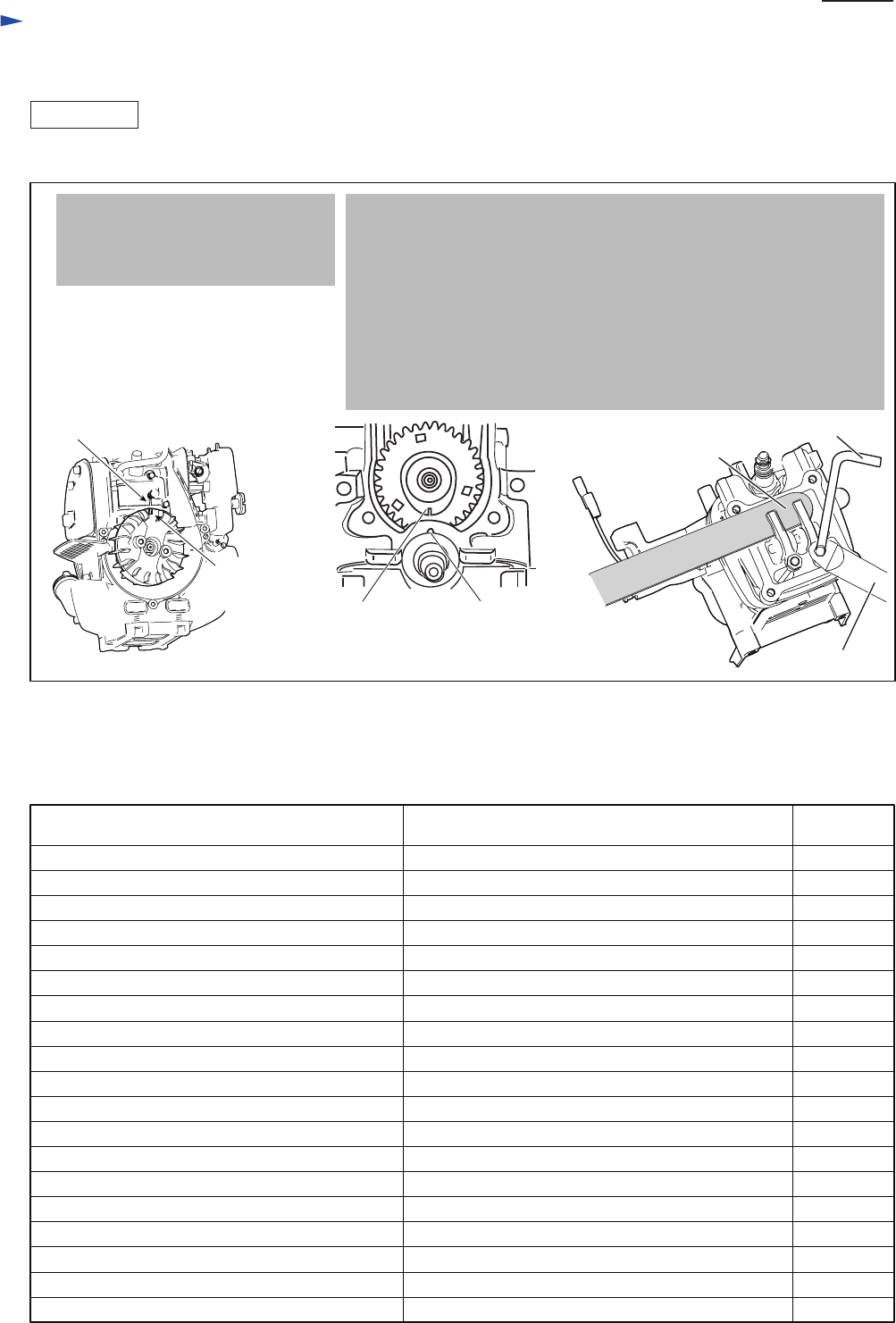

(3) Adjust the valve clearance by following the steps in Fig. 35.

Fig. 35

ASSEMBLY

Marking on Ignition coil

Marking

on

Flywheel

Marking

on

Cam gear

assembly

Marking

on

Cylinder block

1R366

(0.1mm Feeler gauge)

Offset wrench

Hex wrench 2.5

HEX SOCKET HEAD BOLT M5×16

HEX SOCKET HEAD BOLT M4×10

HEX SOCKET HEAD BOLT M5×16

FLANGE NUT M8

HEX SOCKET HEAD BOLT M4×20 with SW, W, MEC*

HEX SOCKET HEAD BOLT M5×16

NUT M5

HEX SOCKET HEAD BOLT M5×16

CLUTCH BOLT M6×25

HEX SOCKET HEAD BOLT M5×40 with W, MEC*

M10×P1.0

HEX SOCKET HEAD BOLT M5×18 with SW, W*

HEX SOCKET HEAD BOLT M5×18 with SW, W*

M8

HEX SOCKET HEAD BOLT M5×16 with SW, W*

HEX SOCKET HEAD BOLT M5×14 with SW, W*

HEX SOCKET HEAD BOLT M5×14 with SW, W*

HEX SOCKET HEAD BOLT M5×12 with SW, W*

* SW : Spring lock washer

W : Washer

MEC: MEC process (process of locking agent on screws)

NUT (M6)

CYLINDER BLOCK and CRANK CASE

CRANK CASE and RETAINER PLATE

CRANK CASE and OIL CASE

FLYWHEEL and CRANK SHAFT 1

COIL and CYLINDER BLOCK

CAM GEAR COVER and CYLINDER BLOCK

ROCKER ARM ADJUSTING SCREW and NUT

ROCKER COVER OUTER and CYLINDER BLOCK

CLUTCH and FLYWHEEL

MUFFLER and CYLINDER BLOCK

SPARK PLUG and CYLINDER BLOCK

INSULATOR and CYLINDER BLOCK

CLUTCH CASE and CYLINDER, CRANK CASE

PULLEY and CRANK SHAFT 2

RECOIL STARTER and CYLINDER, CRANK CASE

MUFFLER PLATE and CRANK CASE

OIL PIPE and OIL CASE

CONTROL LEVER ASS’Y and SHAFT PIPE COMPL.

CONTROL CABLE and INSULATOR

6.0

3.0

6.0

16.0

4.0

6.0

6.0

6.0

9.0

8.0

11.0

5.0

5.0

6.0

5.0

5.0

5.0

3.0

2.0

Fastening

torque: N•m

Screw/ NutParts to fasten

[4]-15. Fastening torque

Tighten all parts to designated fastening torques below.

Repair

P 14/ 14

(4) Take the reverse step of disassembly for Engine block.

1. Align the markings on Ignition coil

and Flywheel.

2. Align the markings on Cam gear

assembly and Cylinder block.

3. Assemble Cam lifter (2pcs), Rod 2.5 (2pcs) and Rocker arm assembly

(2pcs) to Cylinder block assembly.

Note: Put the ends of Rod 2.5 (2pcs) on the round depression of

Cam lifter and Rocker arm, while holding Rocker arm.

4. Loosen the adjust screw of Rocker arm with Hex wrench 2.5 and Offset

wrench, and put 0.1mm Feeler gauge (1R366) between valves and

Rocker arms, then adjust the valve clearance. Tighten the nuts of

Rocker arm assembly and remove 0.1mm feeler gauge (1R366).

5. The clearance is in order if 0.15mm Feeler gauge can not be inserted

between valves and Rocker arms.