[4] DISASSEMBLY/ASSEMBLY

[4]-10. Carburetor (cont.)

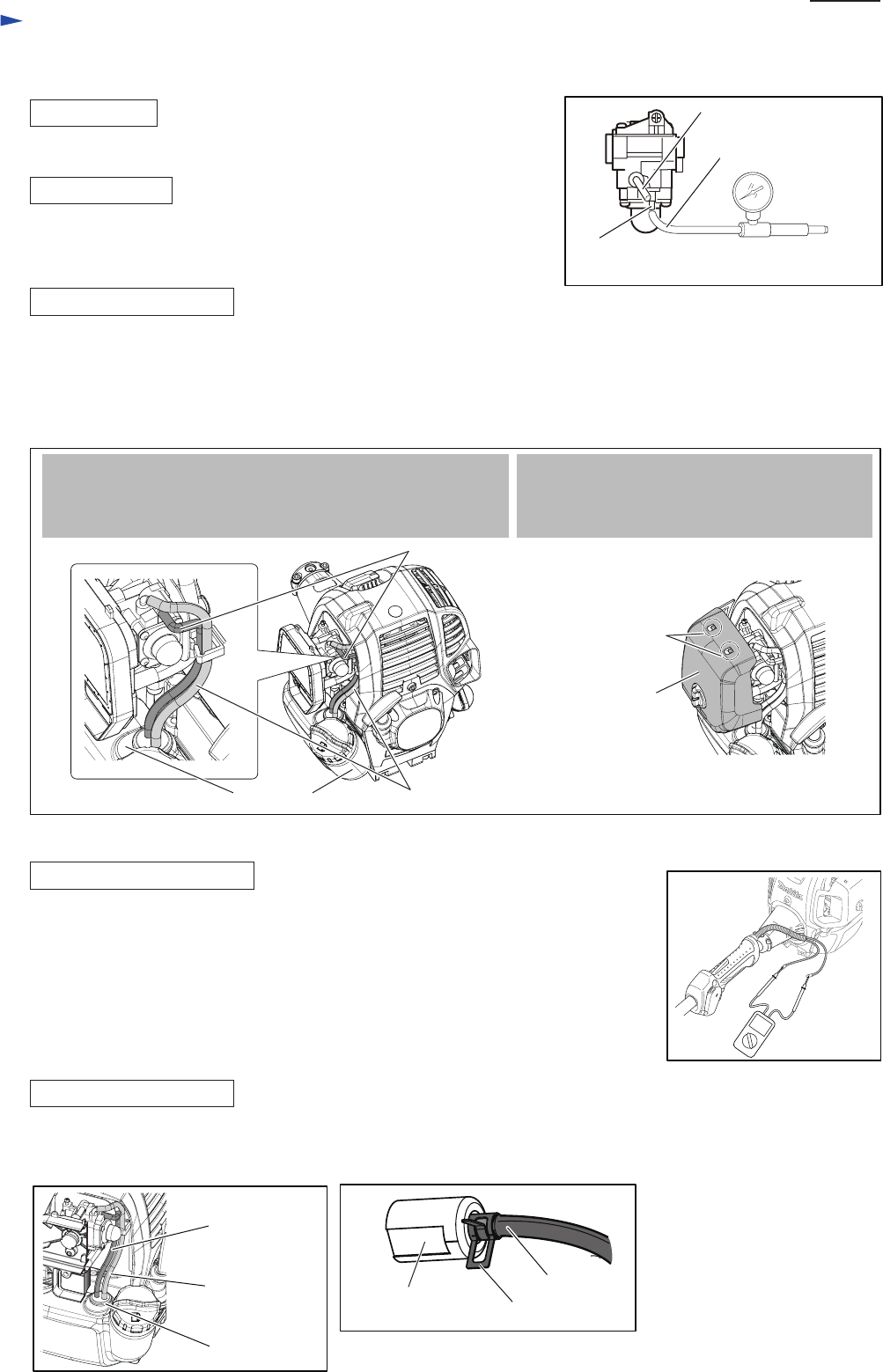

Carefully assemble each part in right direction and order. (Fig. 25)

(1) Assemble Cleaner plate assembly, Carburetor and Gasket to Insulator with two M5x60 Hex socket head bolts.

(2) Connect tubes (black & yellow) of Fuel tank to the nipple of Carburetor, then connect Pipe from Cylinder and

Breather pipe to Cleaner plate. (Fig. 27)

(3) Set Air cleaner elements (sponge at cover side & felt at engine side) in Cleaner plate and

fix Cleaner cover assembly. (Fig. 27)

Check the continuity of two Lead wires’ ends routed from Control lever with Tester.

(Fig. 28)

Stop switch is in order if it works as following:

• Tester shows no connectivity when Engine ON

• Tester shows a connectivity when Engine OFF

(1) Assemble Tube complete; black tube & yellow tube through grommet, to Fuel tank. (Fig. 29)

(2) Assemble Gasoline filter and Hose clamp to the black tube, then put them into Fuel tank. (Fig. 30)

Fig. 26

Fig. 27

Fig. 28

Fig. 30

ASSEMBLING

ASSEMBLY TO ENGINE

Connect 1R127 to the nipple of Carburetor as drawn in Fig. 26.

Give air pressure from 1R127 and check if the pressure gauge indicates

0.05Mpa for around 10 seconds, then there is no problem with Carburetor.

AIRTIGHT TEST

Nipple of Carburetor to connect

black tube of Tank

(Nipple to connect

yellow tube of Tank)

1R127

[4]-11. Stop switch

CHECKING STOP SWITCH

[4]-12. Fuel tube

Hose clamp

Black tube

Gasoline filter

Tabs of Cleaner

plate assembly

Cleaner cover

assembly

Fuel tank

yellow tube

black tube

Fig. 29

grommet

Repair

P 11/ 14

Yellow tube

Black tube

FUEL TUBE ASSEMBLY

1. Connect two tubes (black & yellow) of Fuel tank to

the nipple of Carburetor, then connect Breather pipe and

Pipe from Cylinder to Cleaner plate assembly.

Note: Make sure two tubes do not interfere with Cylinder cover.

2. Set Air cleaner elements (sponge at cover side

& felt at engine side) in Cleaner plate and fix

Cleaner cover by fitting two interlocking tabs

and slots.