17

Section 1: Assembly & Set-up

10/21/15

RC4015 and RCM4015 Series 2 S/N 944961+ Rotary Cutters 330-845M

Table of Contents

Hydraulic Hook-up

The required number of duplex outlets at the tractor is

dependent upon how the cutter is set-up. The standard

cutter is equipped with three hydraulic cylinders with one

in the center for lifting the cutter and one on each wing for

folding the wings simultaneously. All three cylinders are

set-up for single action (one-way) operation.

Each duplex outlet on your tractor can perform only one

operation. One outlet is needed for lifting the cutter and

one for lifting the wings simultaneously. A third outlet is

required if wings are lifted independently. This will also

require replumbing wing cylinders. Float position is highly

recommended for wing outlet(s).

Your Land Pride dealer can help you determine the best

configuration that will match your needs and your tractor

capabilities. An optional control valve kit is available if the

tractor does not have the required number of duplex

outlets. For additional information, see “Selector

Control Valve Kit” on page 35.

!

DANGER

Hydraulic fluid under high pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin or eyes, it must be

treated by a doctor familiar with this type of injury within a

few hours or gangrene may result. DO NOT DELAY.

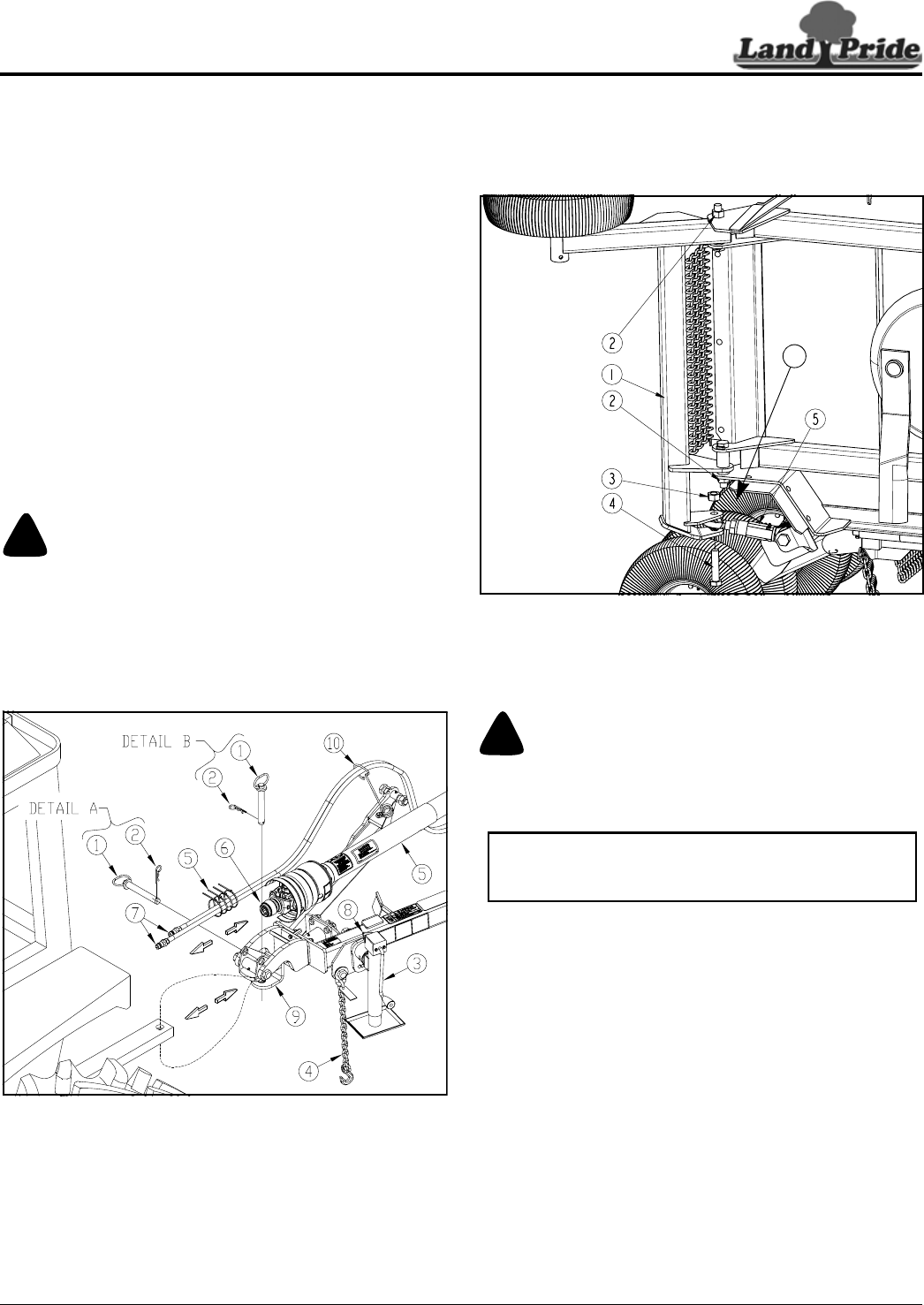

Hydraulic Hook-up (LP Performance Hitch Shown)

Figure 1-15

Refer to Figure 1-15:

1. Route hydraulic hoses (#7) through hose support

loop (#10) and attach couplers to the tractor remote

outlets. If tractor has a float option on one of the

outlets, connect wing lift hose to that outlet and set

tractor control lever for that outlet in float position

before cutting.

37631

2. Secure hydraulic hoses together with zip ties (#12)

as needed to keep them from pinch areas caused by

raising and lowering the deck, folding the wing up

and down, and while making turns with the tractor.

Wing Axle - Turnbuckle Assembly

Figure 1-16

Right & Left Wing Set-up

Refer to Figure 1-16:

!

WARNING

Connect turnbuckles (#5) to wing axles (#1) before lowering

wings. Otherwise, personal injury and/or damage to the

turnbuckle can occur.

1. Park tractor and cutter on a level surface.

2. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 13.

3. Cut metal band between the two wing axles.

4. On the right wing axle, loosen lock nuts (#2) slightly

to allow rotation of the axle.

5. Remove locknut (#3) and 1 1/4" hex head bolt (#4).

6. Loosen jam nut (#6) on turnbuckle (#5) and adjust

until center of ball swivels are approximately 10 1/2"

apart. Do not retighten jam nut. Final adjustment will

be made later when leveling wing decks.

7. Rotate right axle (#1) until turnbuckle (#5) can be

attached to the axle with existing bolt (#4) and lock

nut (#3). Tighten locknut (#3) to the correct torque.

8. Tighten locknuts (#2) until snug. Do not over tighten.

Wing axle must be able to pivot in the field.

9. Repeat steps 4 thru 6 for the left wing axle.

27929

6

NOTE: Wing axle locknuts (#2) are tightened for

shipping purposes. They must be loosened slightly

to allow the axle to pivot. Do not torque them tight.