25

Section 5: Maintenance & Lubrication

12/15/15

RCD1884 Rotary Cutters 326-355M

Table of Contents

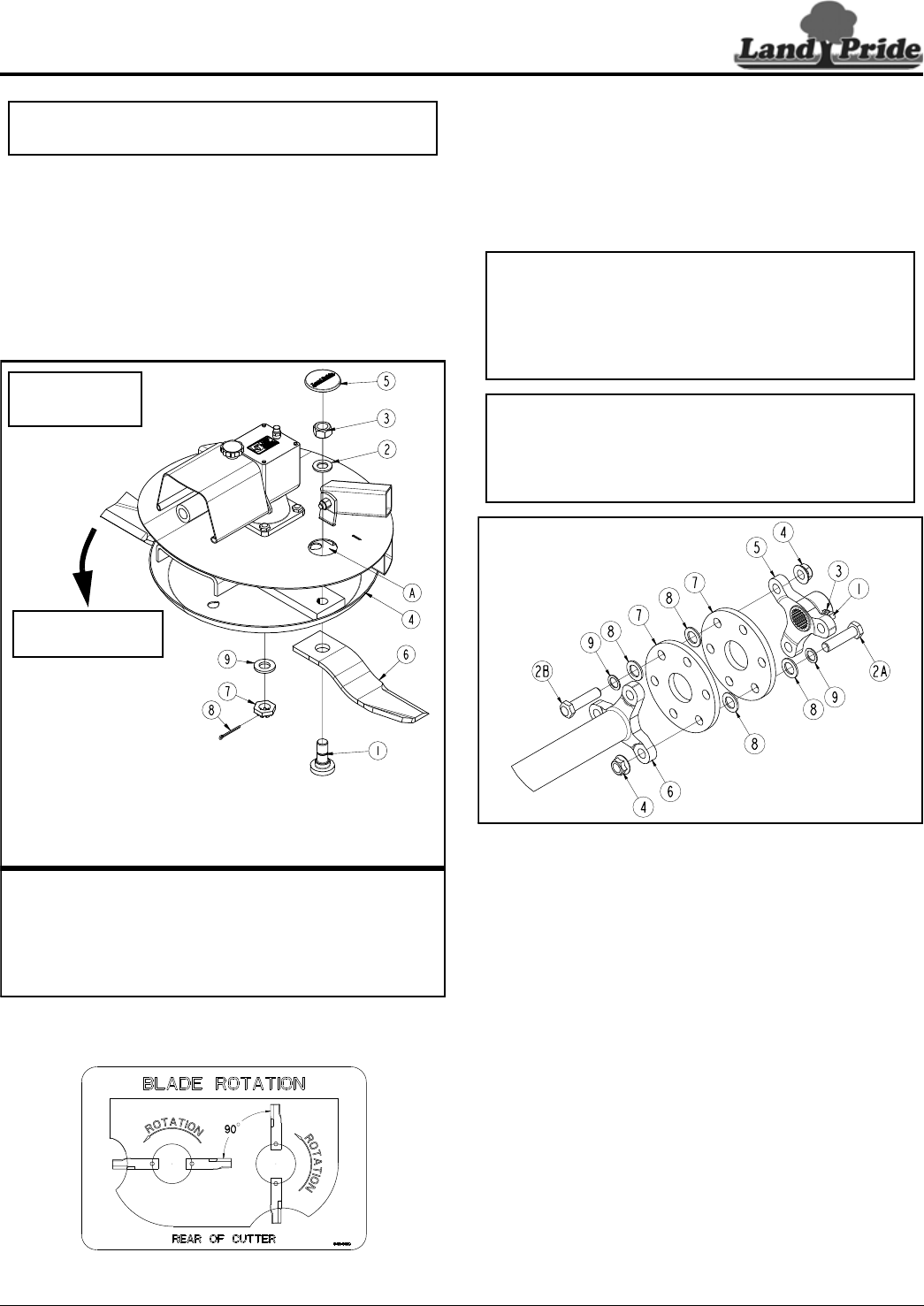

8. Insert blade bolt (#1) through blade (#6), dish

pan (#4), and flat washer (#2). Secure blade with a

new locknut (#3) and torque to 450 ft-lbs.

9. Replace access cover (#5).

10. If replacing dishpan (#4), castle nut (#7) on gearbox

output shaft should be torqued to 450 ft-lbs. minimum

and secured with cotter pin (#8) with both legs bent

opposite directions around the nut.

Cutter Blade Assembly

Figure 5-1

Blade Rotation & Timing

Figure 5-2

IMPORTANT: Examine blade bolts (#1) and flat

washers (#2) for excessive wear and replace if worn.

33002

Counterclockwise

Blade Rotation

Use 1-11/16"

Socket Wrench

On Blade Nut (#3)

Land Pride Cutter Blade Parts

Item Part No. Part Description

318-586A BLADE BOLT KIT (items 1, 2, & 3 below)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 804-147C WASHER FLAT 1 HARD ASTMF436

3 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

4 326-234H ROUND DISHPAN WELDMENT

5 840-273C PLUG LP 3" ID RUBBER

6 820-443C CUTTER BLADES 1/2" x 4" x 16" LG. CCW

Flex Coupler & Blade Timing

Refer to Figure 5-3:

If rubber discs (#7) are wrinkled, the blades may be out of

time and hit each other. Replace rubber disc if blades hit.

Follow instructions below when replacing rubber discs

and when adjusting blade timing.

Flex Coupler Assembly

Figure 5-3

1. Unbolt/remove rubber discs (#7) from flex coupler.

Keep rubber discs that are in good shape and

replace them if they are wrinkled excessively.

2. Loosen jam nut (#3) and set screw (#1).

Slide spider (#5) off main gear box output shaft.

3. Rotate cutter blades until blades on the left dishpan

are 90

o

to blades on the right dishpan.

4. Hold blades 90

o

apart. Center spider lugs (#5)

between spider tube lugs (#6) and push spider (#5)

onto main gearbox output shaft.

5. Attach rubber discs (#7) to spider tube lugs (#6) with

existing bolts (#2A), washers (#9), bushing (#8), and

hex flange locknuts (#4) as shown. Do not tighten.

6. Attach rubber discs (#7) to spider lugs (#5) with

existing bolts (#2B), washers (#9), bushing (#8), and

hex flange locknuts (#4) as shown. Do not tighten.

7. Tighten nuts (#4) evenly until rubber disc (#7) touch

each other at each bolt location. Bushings (#8)

should be compressed halfway into the rubber discs.

IMPORTANT: See Figure 5-2. Cutter blades must be

90 deg. to each other to be in time or blades will

contact each other when hitting solid objects such as

tree stumps, rocks and earth. Blades hitting each

other will become bent, broken, or twisted and

require being replaced immediately.

IMPORTANT: Through use, rubber discs (#7) will

become wrinkled from hitting solid objects causing

blades to be out of time. Replace rubber disc when

wrinkling causes blades to make a ticking sound

from touching each other while cutting heavy brush.

33025