12

Section 1: Assembly & Set-up

RCD1884 Rotary Cutters 326-355M

12/15/15

Table of Contents

tractor off, and remove switch key.

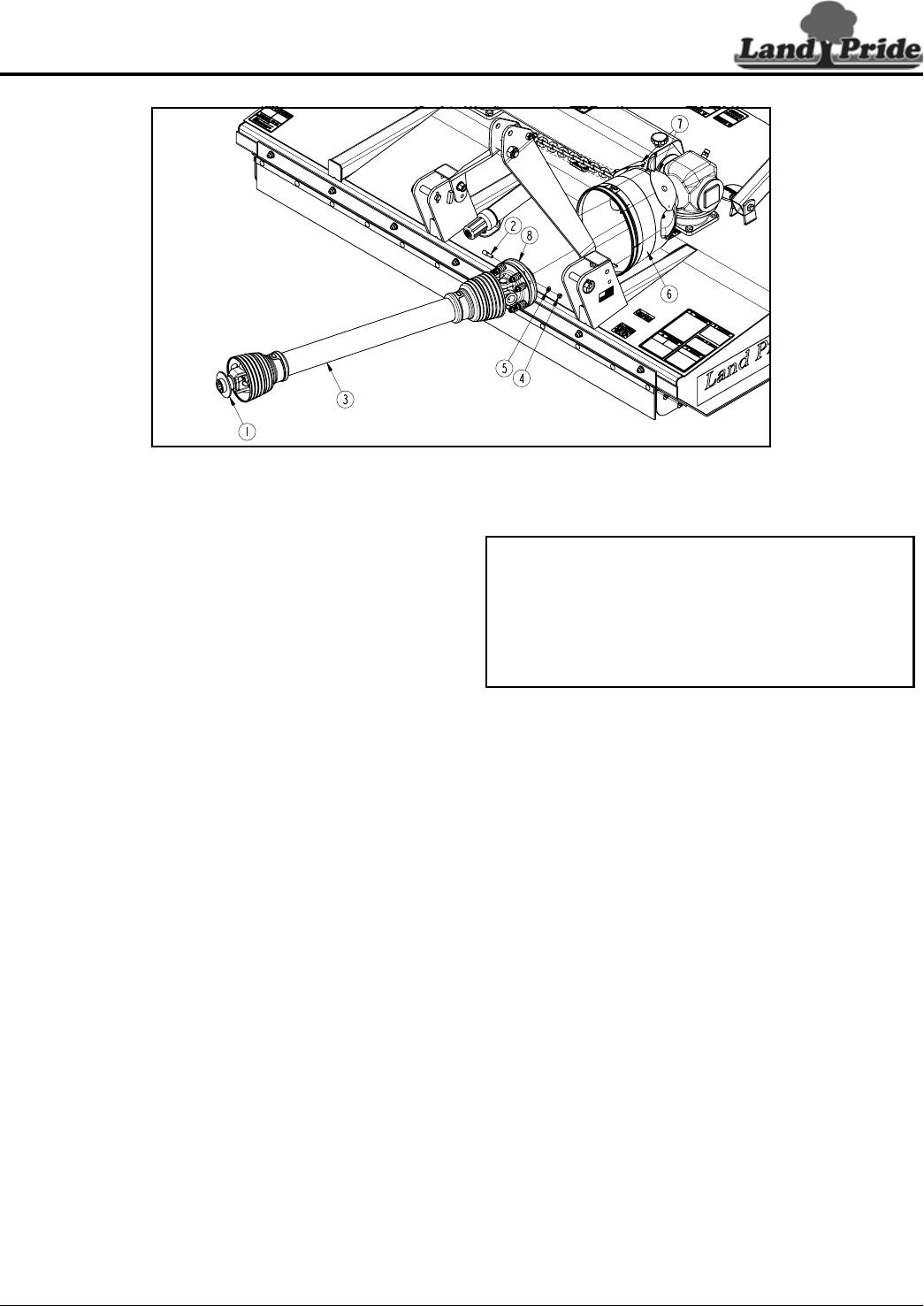

Refer to Figure 1-5:

4. Remove tapered pin (#2) from slip-clutch (#8).

5. Unsnap access doors (#7) from gearbox cone (#6)

and rotate about the metal pin either up or down to

gain access to the gearbox input spline shaft.

6. Slide slip-clutch end of driveline onto gearbox input

shaft until holes in slip-clutch align with notch in

gearbox shaft.

7. Insert tapered pin (#2) and secure with removed

washer (#5) & hex nut (#4). Tighten hex nut to the

correct torque.

8. Move slip-clutch back and forth several times to

make sure it is locked onto gearbox shaft.

9. Replace access covers (#7).

10. Pull back on yoke collar (#1) and push driveline yoke

onto the tractor PTO shaft. Release pull collar and

continue to push driveline yoke forward until pull

collar locks in place.

11. Move driveline yoke back and forth several times to

make sure yoke is locked in place. If driveline yoke

will not lock in place, skip to “Check Driveline

Collapsible Length” on page 12.

12. Continue with “Check Driveline Collapsible

Length”.

Check Driveline Collapsible Length

1. Make sure driveline is properly installed and level

before checking driveline collapsible length. (Refer to

“Driveline Installation” instructions on page 11.)

Refer to Figure 1-6 on page 13:

2. With driveline level, measure (“B” dimension) back

from universal joint shield to end of outer driveline

shield as shown in Figure 1-6. If measurement is less

than 1", then shorten driveline using instructions

provided below.

3. Skip to “Check Driveline Maximum Length” on

page 13 if “B” dimension is 1" or more.

Shorten Driveline

Refer to Figure 1-6 on page 13:

Be sure to check driveline collapsed length first. If

required, shorten driveline.

1. Unhook driveline from tractor PTO shaft. Pull outer

and inner drivelines apart.

2. Reattach outer driveline to tractor PTO shaft. Pull on

inner and outer driveline yokes to be sure universal

joints are properly secured.

3. Hold inner and outer drivelines parallel to each other:

a. Measure 1" (“B” dimension) back from outer

driveline universal joint shield and make a mark at

this location on the inner driveline shield.

b. Measure 1" (“B” dimension) back from the inner

driveline universal joint shield and make a mark at

this location on the outer driveline shield.

IMPORTANT: A driveline that is too long can bottom

out causing structural damage to tractor and cutter.

Always check driveline collapsed length during initial

setup, when connecting to a different tractor, and

when alternating between using a quick hitch and a

standard 3-point hitch. More than one driveline may

be required to fit all applications.

Driveline Installation

Figure 1-5

33001