14

Section 2: Operating Instructions

OS1548 and OS1572 Overseeder (S/N 166724+) 308-303M

2-16/09

Land Pride

Table of Contents

Section 2: Operating Instructions

Operating Check List

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence and proper

training involved inthe operation, transport, maintenance

and storage of the seeder. Therefore, it is absolutely

essential that no one operates the Overseeder without

first having read, fully understood and become totally

familiar with the Operator’s Manual. Make sure the

operator has paid particular attention to:

• Important Safety Information, pages 1 to 3

• Section 1: Assembly & Set-up, page 9

• Section 2: Operating Instructions, page 14

• Section 3: Adjustments, page 18

• Section 4: Maintenance & Lubrication, page 31

The following information should be known and

inspections made before operating your seeder.

Operating Checklist

✔ Check

Page No.

Read and follow all Safety Rules carefully.

Refer to “Important Safety Information”. Page 1

Make sure all guards and shields are in place.

Refer to “Important Safety Information”.

Page 1

Read and follow Hook-up & preparation instructions.

Refer to “Section 1: Assembly & Set-up”. Page 9

Read and follow all operating procedures.

Refer to “Section 2: Operating Instructions”. Page 14

Read and make all required adjustments.

Refer to “Section 3: Adjustments”. Page 18

Read and follow all Maintenance Instructions.

Refer to “Section 4: Maintenance & Lubrication”.

Page 31

Read and follow all Lubrication Instructions.

Refer to “Lubrication Points”.

Page 38

Make sure all gearboxes are properly lubricated.

Refer to Gearbox lubrication. Page 40

Check tire pressure. Refer to “Tire Inflation Chart” Page 48

Inspect seed cups and seed tubes for foreign matter. Page 18

Set speed change sprocket for drive type desired. Page 19

Set seed rate. See “Seed Rate Charts”. Page 20

Check seeder initially and periodically for loose bolts

and pins. Refer to “Torque Values Chart”. Page 48

Tractor Hook-Up

!

DANGER

Tractor hook-up to equipment is dangerous and can result in

serious injury or death. Do not allow anyone to stand between

the seeder and tractor during hook-up operations. Do not

operate hydraulic 3-point lift controls while someone is

directly behind the tractor or near the seeder.

When using tractors with multispeed PTO, be certain

PTO is set for 540 RPM.

1. Slowly back tractor up to Overseeder while using the

tractor’s hydraulic control to align the tractor’s lower

hitch link holes with the seeder’s clevis lug holes.

2. Engage tractor park brake, shut tractor engine off

and remove key before dismounting from tractor.

3. Attach tractor’s 3-Point lower links to the seeder’s

lower hitch clevises using 7/8” diameter hitch pins.

Secure hitch pins with linch pins.

4. Attach tractor’s top center link to the seeder’s top

hitch using a 3/4” diameter hitch pin. Secure hitch pin

with a linch pin.

5. Ensure that the lower hitch arms are blocked to

prevent excessive side movement.

6. Return to tractor and slowly operate controls up and

down to make sure seeder clears tractor tires, frame

and drawbar. Move or remove drawbar if it interferes.

7. Manually adjust one of the tractor’s lower lift arms up

or down to level the seeder from left to right.

8. With the seeder resting on level ground, manually

adjust tractor’s top link until the seeder is level from

front to rear.

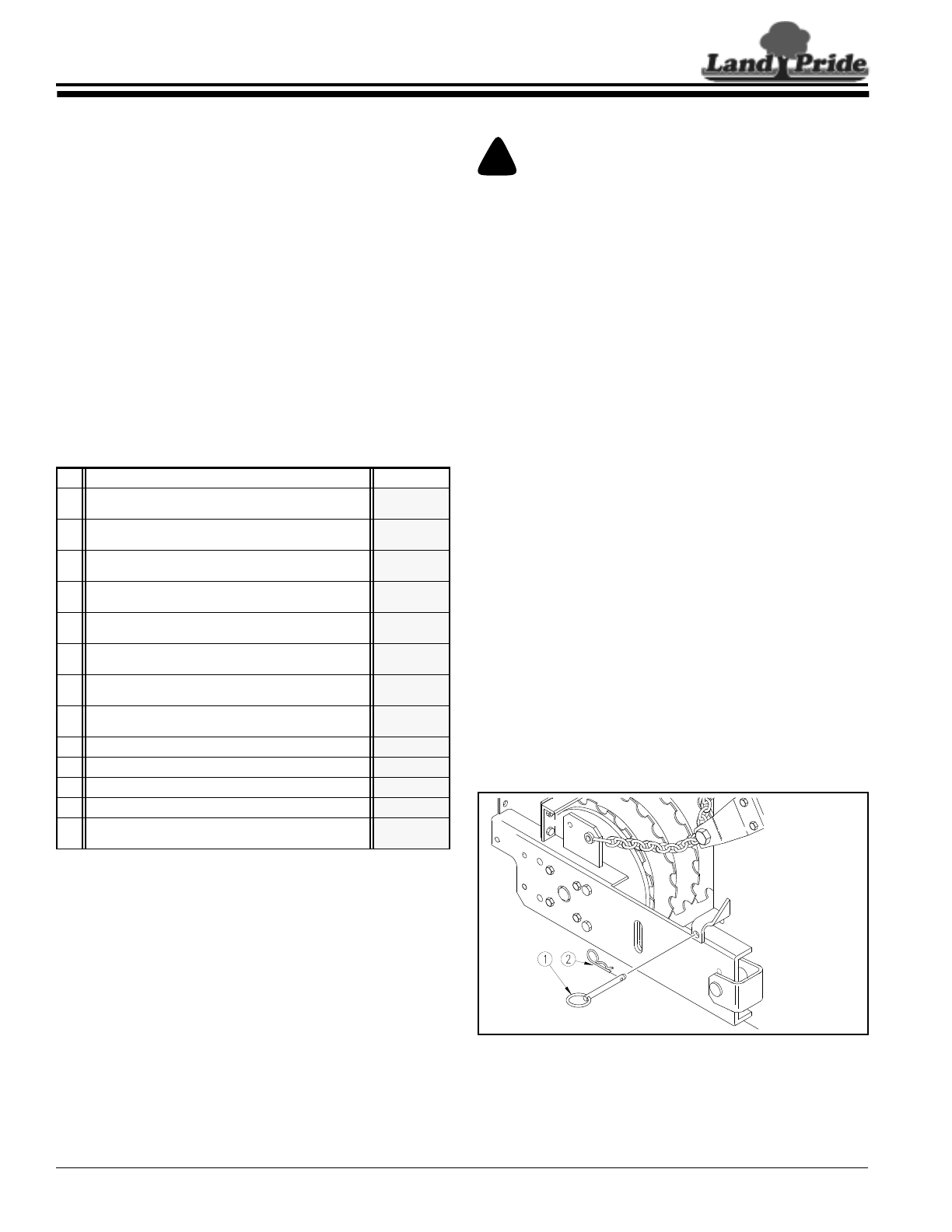

Refer to Figure 2-1:

9. Remove rear roller stop pin (#1) and hairpin

cotter (#2) out of parking position.

Rear Roller Stop Pin in Parking Position

Figure 2-1

14669