18

Section 5: Maintenance & Lubrication

AR2596 & AR2510 Pasture Aerators 325-127M

12/09/15

Table of Contents

Introduction

Proper servicing and adjustments are key to the long life

of any implement. With careful inspection and routine

maintenance, you can avoid costly downtime and repair.

Check all bolts after using the unit for several hours to be

sure they are tight. Replace any worn, damaged, or

illegible safety labels by obtaining new labels from your

Land Pride dealer.

!

CAUTION

Do not alter Land Pride equipment or replace parts with other

brands. Doing so can cause equipment to perform improperly

and may lead to breakage that can cause bodily injury.

Replace parts only with genuine Land Pride parts.

Tractor Maintenance

One of the most important things you can do to prevent

hydraulic system problems is ensure that your tractor's

reservoir remains free of dirt and contamination. Use a

clean cloth to wipe hose ends before attaching them to

your tractor. Replace your tractor’s hydraulic filter

element at the prescribed intervals. These simple

maintenances will go a long way to prevent occurrence of

control valve and hydraulic cylinder problems.

Tine Replacement

Refer to Figure 5-1:

!

WARNING

Always secure Aerator in the up position with solid supports

before servicing the underside. Never work under equipment

supported by hydraulics. Hydraulics can drop equipment if

controls are actuated or if hydraulic lines burst. Either

situation can drop the Aerator instantly even when power to

the hydraulics is shut off.

“Right-Hand” or “Left-Hand” as used in this manual is

determined by facing the direction the machine will

operate while in use.

Stamped on the tines (see Arrows in Figure 5-1) is

Land Pride’s name, tine part number, and LH for left-hand

or RH for right-hand tine designation.

Refer to Figure 5-3 on page 19:

1. Loosen 8 nuts (#2) on one hub two or three turns.

2. Remove two bolts (#1) securing tine (#4) if working

on the Left-Hand Gang or tine (#5) if working on the

Right-Hand Gang.

IMPORTANT: Make sure right-hand tines are

mounted on the right-hand gang and left-hand tines

are mounted on the left-hand gang and that the knife

edge leads as the tine rotates about the shaft.

IMPORTANT: Tines are bolted on in a Spiral pattern

22.5 degrees from one blade to the blade on the next

flange over. Arrow in Figure 5-2 shows tines shifting

22.5 degrees from one hub assembly to the next.

3. Examine removed hardware for wear. Replace worn

hardware with new hardware if required.

4. Examine stamped information on the removed tine.

Replace worn tine with a new tine that has the same

stamped information.

5. Install new tine (#5 or #6) by sliding one hardened flat

washer (#3) over each 1/2"-20 x 3" GRL9 cap screw

(#1) and then inserting the two cap screws into the

thicker 5/8" plate first. After the bolt has been fully

inserted, slide a second hardened flat washer onto

the two cap screws as shown.

6. Apply Loctite 246 on the end 1/4" length of threads.

Screw hex flange lock nuts (#2) onto the cap screws

on 3 or 4 turns only. Do not tighten.

7. Repeat steps 2 to 5 until all four tines on a single hub

have been replaced.

8. Tighten all 8 hex flange lock nuts (#2) on that hub to

the correct torque. See “Additional Torque Values”

on page 24 for correct torque value.

9. Move on to the next hub and repeat steps 1 to 8.

10. Continue reworking one hub at a time until all worn

tines have been replaced with new tines.

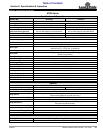

Right-Hand & Left-Hand Tines

Figure 5-1

Spiral Pattern of Tines (Left-Hand Gang Shown)

Figure 5-2

IMPORTANT: Bolt installation direction is critical.

Always insert bolts into the thicker 5/8" plate first.

IMPORTANT: Loctite 246 should be applied to the

cap screw threads before installing lock nuts.

Right-Hand Tine

Pt. No. 820-408C

27730A

Left-Hand Tine

Pt. No. 820-407C

Knife Edge

Knife Edge

30071

Section 5: Maintenance & Lubrication