20 –English

INSTALLATION

Propulsion

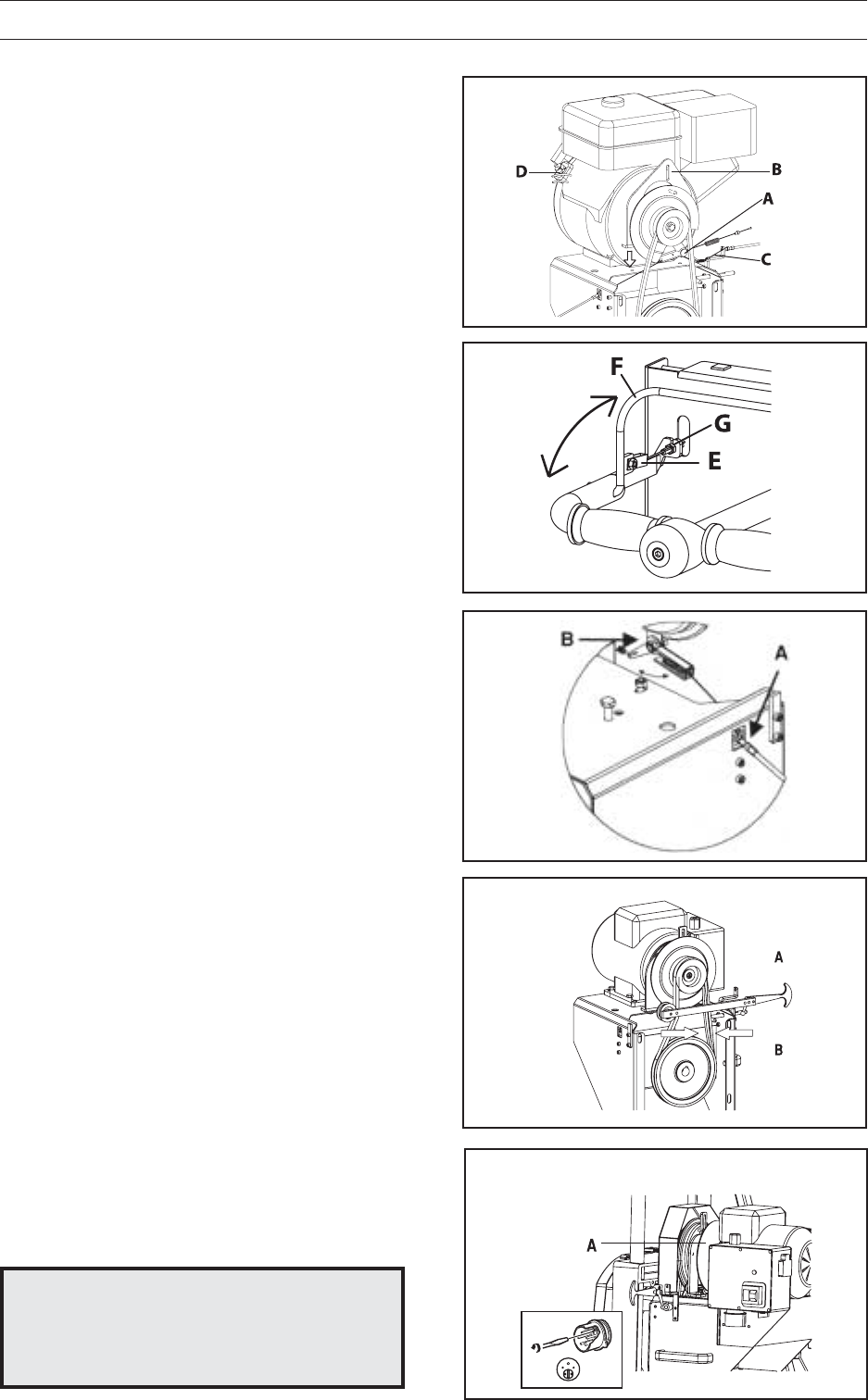

1. Place the engine/motor on the engine/motor

console and attach the drive belt.

2. Bolt the engine/motor (petrol or electric) onto

the engine/motor console.

3. Connect the cable to the clutch control arm

(A).

4. Attach the mounting for the drive disc (B), so

that the clutch does not rotate.

5. Tighten the belt with the belt tension device

(FIG. 31 A). A correctly adjusted belt can be

moved 0.5 cm with one finger (FIG. 31 B). If

necessary, adjust the engine/motor console

mounted in the lengthways slot to attain the

correct belt tension.

6. Connect the cable to the start lever (FIG. 30

E), check that the clutch is activated. When

the start lever (FIG 30 F) is activated, the

spring in the control arm on the clutch shall

be lightly compressed.

Wire adjustment

The wire that engages the clutch must be ad-

justed so that there is no pressure on the clutch

arm that is connected to the clutch. The easiest

way to do this is to adjust the wire so that it is

completely slack when the clutch is not engaged.

Adjustment is by means of the adjuster nipples

on the starter yoke and the engine bracket (FIG

30 G and FIG X A).

It is also important that the attachment to the

clutch is able to swing (FIG X B). The spring in

the fastener prevents excessive leverage being

applied to the clutch arm.

On saw mills with four-stroke engines, the wire

connected to the engine is adjusted using nipple

(FIG X), so that the throttle lever is activated by

the swinging motion (FIG X B) of the wire faste-

ner near the clutch and therefore increases the

engine speed before the clutch is engaged.

Petrol Engine

Connect the cable from the covers’ safety switch

(22) to the contact (FIG. 29 D) on the engine.

Electric Motor

Connect the cable from the covers’ safety switch

to the contact on the distribution box (FIG. 32 A).

The contact for the electrical cable for the electric

motor has polarity reversal (31). Make sure that

the main switch (34) is set to 0.

WARNING!

Check that the main switch is

set to 0, and be sure to invert

the phase if the sawmill runs in

the wrong direction.

!

FIG 29

FIG 30

FIG 31

FIG 32

FIG X