English – 15

DESCRIPTION

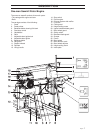

Band Wheel Guard (21)

The band wheels are protected from contact by a

cover on each side. Each cover is equipped with

a safety key that cuts the mains power to the

start switch for units with an electric motor and

short-circuits the petrol engine when the covers

are removed. There are 3 rubber straps on the

guard to allow easy dismantling and assembly

when changing the bandsaw blade. The safety

key activates a safety switch when the covers are

fitted. The rail stop (FIG. 14A) prevents the

bandsaw carriage from rolling off the rails.

Safety Devices

The one-man saw is fitted with a number of

safety devices, which are described under the

headings below.

Bandsaw Blade Guard (lower)

(23)

The part of the bandsaw blade that is not in the

log when cutting should be covered by the

adjustable guard.

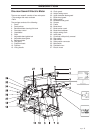

Bandsaw Blade Brake (FIG. 16)

The bandsaw is equipped with an integrated

brake/clutch (A) that stops the band wheel in

order to quickly stop the band wheel when the

handlebar controls (4) are released.

Starter, Electric Motor (FIG. 17)

The electrically powered saw is equipped with a

main switch (35), safety switch connector with

phase inverter (31), contact for safety switch (A),

and start switch (33). The motor is started with

the green start switch and stopped with the red

stop switch (32). The electric motor stops when

not in use for longer periods or when sawing is

completed. The starter is equipped with a 0-volt

trigger. This means that the sawmill’s electric

motor must be restarted after a power outage.

Stop Switch, Petrol Engine (14)

On the petrol engine, the stop switch is located

on the engine body and with electric start the

engine is stopped with the key.

WARNING!

The one-man saw must not be

started if any of the safety

devices have been removed,

are defective, or are not

working.

Bandsaw Blade Guard (upper)

(20)

The upper section of the bandsaw blade runs in

a slot.

!

FIG 14

FIG 15

FIG 16

FIG 17