47

6

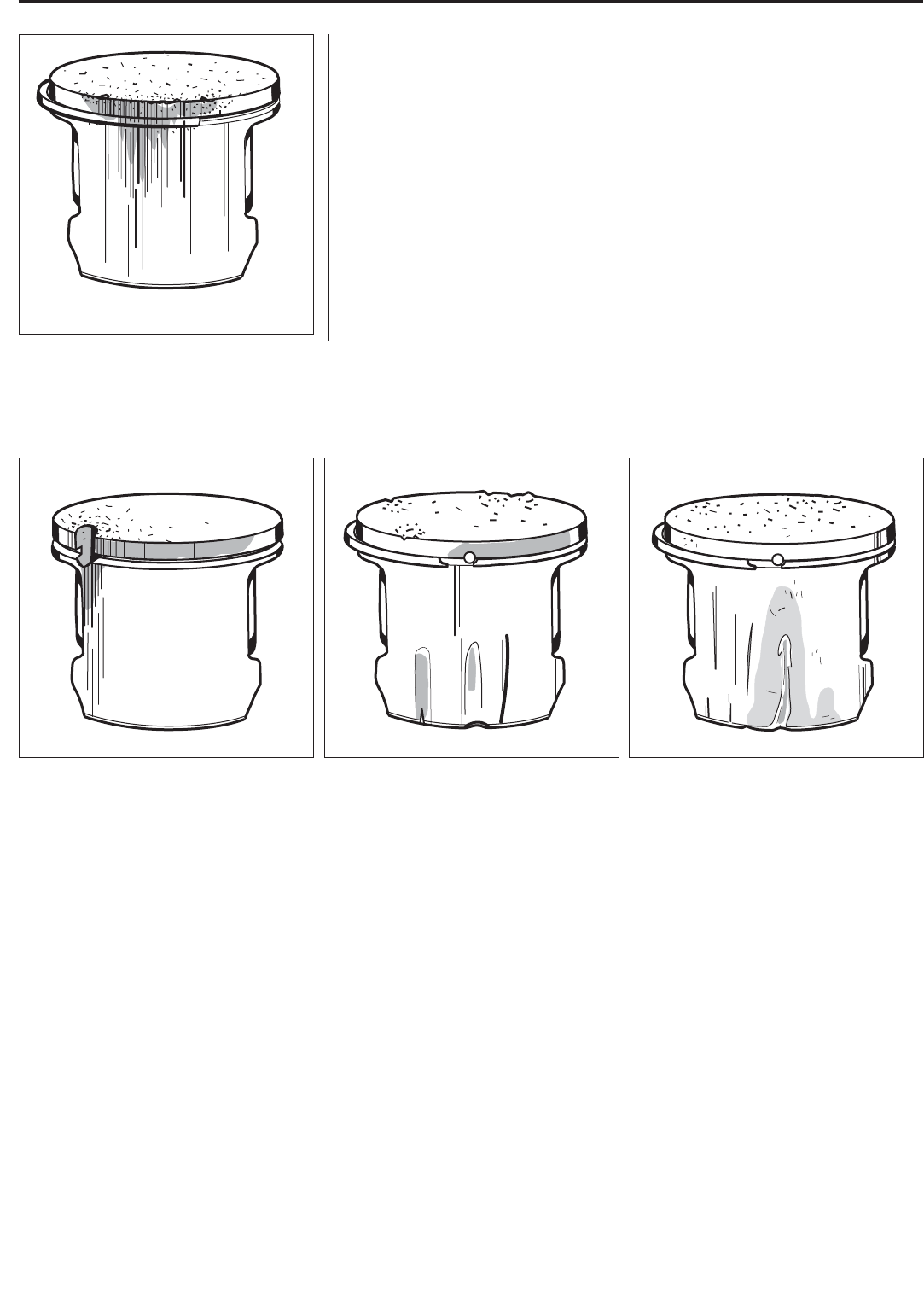

Cylinder and piston

Exhaust side damaged by a broken piston

ring. The piston ring parts damage the top

section and cause score marks.

Piston damage caused by a too high engine speed.

Typical damage associated with a too high engine speed includes broken piston

rings, broken circlip on the gudgeon pin, faulty bearings or that the guide pin for the

piston ring has become loose.

Piston ring breakage

A too “lean” carburettor setting results in a too high speed and a high piston

temperature. If the piston temperature rises above the normal working temperature

the piston ring can seize in its groove, consequently it will not sit deep enough in its

groove. The edges of the piston ring can then hit the top edge of the exhaust port

and be smashed and also cause piston damage.

A too high engine speed can also cause rapid wear to the piston ring and play in

the piston ring groove primarily in front of the exhaust port. The ring is weakened by

the wear and can be caught in the port causing serious piston damage.

The guide pin for the piston ring has been

pushed up through the top of piston.

Irregular grooves on the piston’s inlet side

caused by a broken roller retainer.

Deep, irregular grooves caused by a loose

circlip. Shown here on the piston’s inlet

side.

Piston ring guide pin

vibrated loose

A too high engine speed can cause the

ends of the piston ring to hammer against

the guide pin when the piston ring moves

in its groove. The intensive hammering

can drive out the pin through the top of

the piston causing serious damage also

to the cylinder.

Damage caused by

gudgeon pin circlips

A too high engine speed can cause the

gudgeon pin circlips to vibrate. The

circlips are drawn out of their grooves due

to the vibrations, which in turn reduces

the circlips’ tensioning power. The rings

can then become loose and damage the

piston.

Bearing failure

Failure of the crankshaft bearing or on the

connecting rod bearing is usually caused

by a too high engine speed, resulting in

the bearing being overloaded or overheat-

ing. This in turn can cause the bearing

rollers or ball to glide instead of rotate,

which can cause the roller or ball retainer

to break.

The broken debris can be trapped be-

tween the piston and cylinder wall,

damaging the piston skirt.

Debris can also pass up through the

cylinder’s transfer channels and cause

damage to the top and sides of the piston

as well as to the cylinder’s combustion

chamber.