24

3

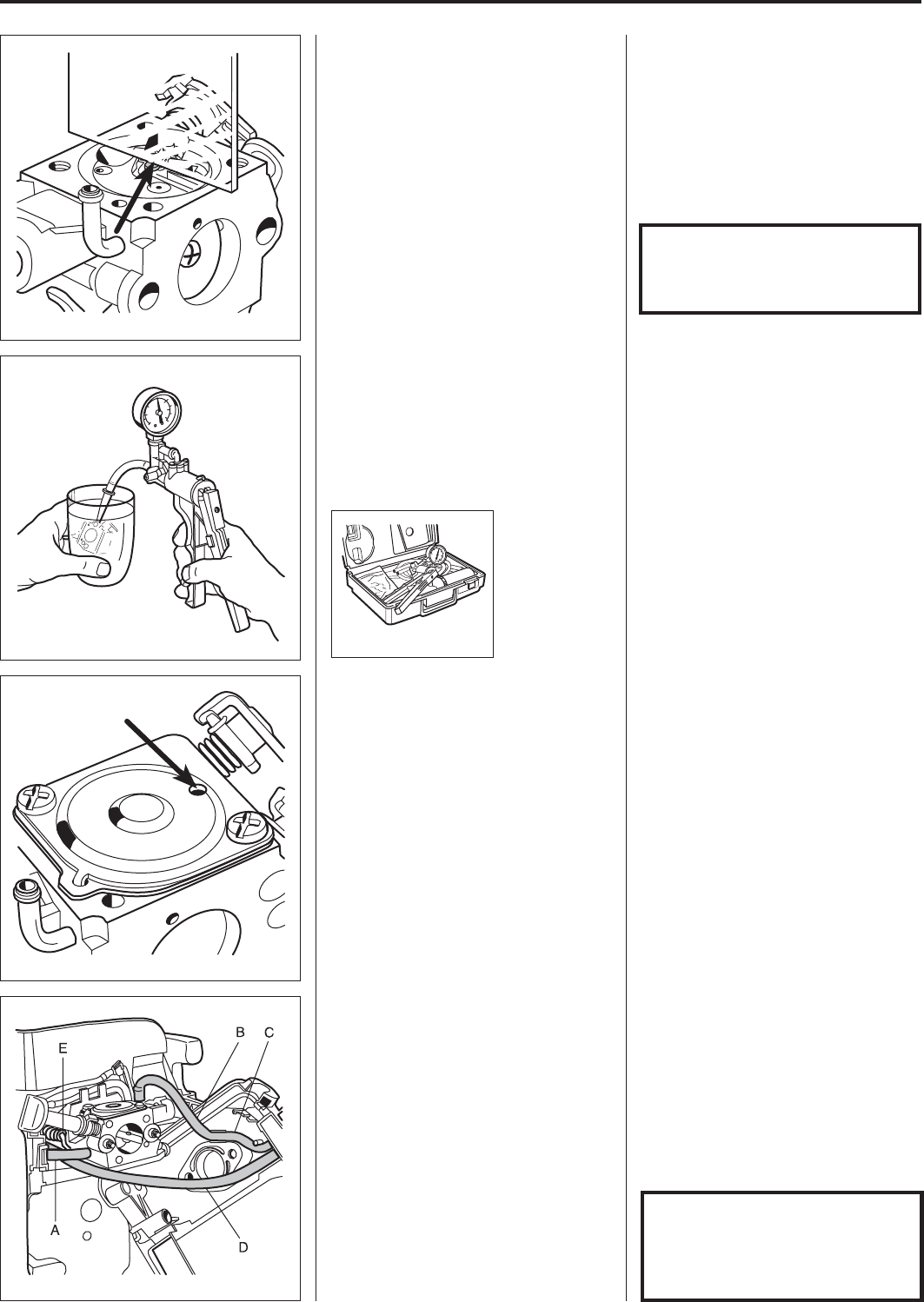

531 03 06-23

Fuel system

Check that the carburettor is sealed.

No leakage is permitted at 50 kPa.

Connect pressure tester 531 03 06-23

to the fuel intake on the carburettor.

Pump up the pressure to 50 kPa.

Lower the carburettor in a vessel with

petrol in order to discover any leaks

more easily.

No leakage is permitted.

Attach the control diaphragm and

cover.

Place the gasket on the carburettor

housing and then the control dia-

phragm.

Check that the air hole in the cover is

open and screw the cover on.

Assembly

Slide the carburettor into place and

connect the fuel hoses.

Make sure that they do not get pinched.

Connect the throttle cable to the

carburettor.

Assembly

Slide the carburettor into place.

Connect the fuel hose (A) to the carburettor.

Connect the fuel hose (B) to the carburettor

and make sure that it is in the groove (C).

Place the filter holder in place and make

sure that the fuel hose (D) is under the

carburettor and is not pinched.

Connect the throttle cable (E) to the

carburettor.

Screw down the filter holder and attach

the air filter.

Attach the various parts of the measur-

ing unit in the reverse order as set out

for dismantling.

Attach the various parts of the measur-

ing unit in the reverse order as set out

for dismantling.

The lever arm should lie flush with the

carburettor housing.

Too high setting = too much fuel.

Too low setting = too little fuel.

NOTE!

The H-needle is a little shorter

than the L-needle.

NOTE!

Check carefully that the fuel hoses

are not bent or pinched when the

fuel tank is pushed back into

place against the engine body.