25

3

T

Fuel system

The needles must be correctly adjusted in order for the engine to give maximum

power at different speeds, run steadily while idling and to react quickly when

accelerating.

The setting of the carburettor can vary a little depending on the humidity, tempera-

ture and air pressure.

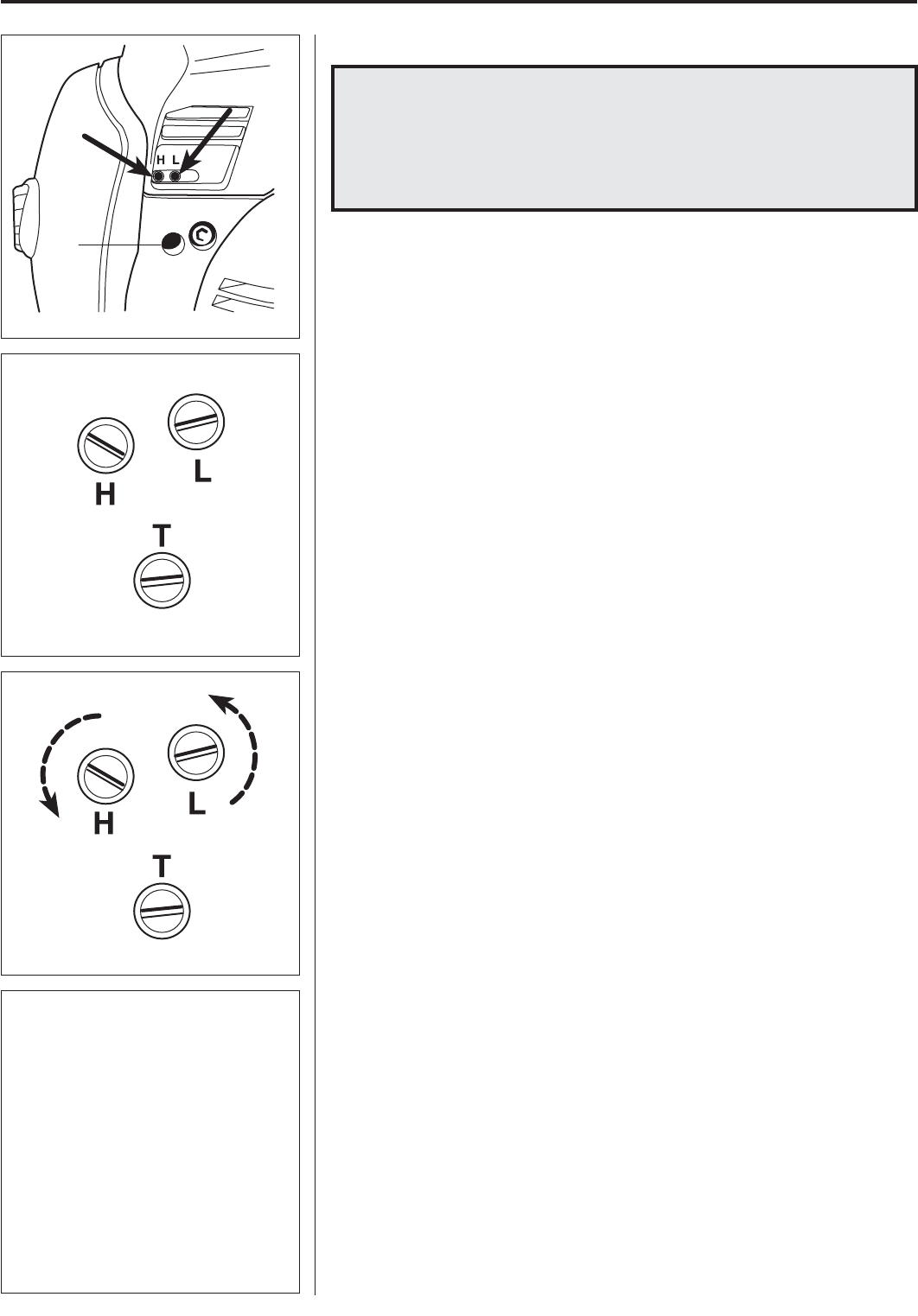

L = Low speed needle

H = High speed needle

T = Idle adjustment screw

• The fuel quantity in relation to the air flow permitted by the throttle opening is

adjusted by the L and H jets. Turning the needles clockwise gives a leaner fuel

mixture (less fuel) and turning them anticlockwise gives a richer fuel mixture (more

fuel).

A leaner

mixture gives

higher

revs while

a richer

mixture gives

less

revs.

• The T-screw regulates the position of the throttle while the engine is idling.

Turning the screw clockwise gives a higher idling speed while turning it anti-

clockwise gives a lower idling speed.

Basic setting

The carburettor is set to its basic setting when test run at the factory. The basic

setting is “richer” than the optimal setting (fast idle speed is 600–800 rpm under the

recommended max. speed) and should be kept during the engine’s first working

hours. Thereafter the carburettor should be fine tuned.

The default setting is:

H = 1 revolution open

L = 1 revolution open

Carburettor settings

Function

The carburettor has the task of supplying a combustible fuel/air mixture to the

cylinder.

The amount

of this mixture is controlled by the throttle.

The mixture’s composition

of fuel and air is controlled by means of the adjustable

“H” and “L” needles.

WARNING!

When testing the engine in connection with carburettor

adjustment, the clutch and clutch cover must be mounted

together with the shaft and angle gear under all circumstances

Otherwise there is a risk of the clutch becoming loose resulting in

serious personal injury.

!

Fine adjustment

Fine adjustment of the carburettor should be carried out after the engine has been

“run-in”.

• The air filter should be clean and the cylinder cover fitted when all adjustments

are made.

First adjust the L-needle, then the H-needle and finally the idling speed’s T-

screw.

Idling speed = 2,800 rpm.

• Since the ignition system is limited in terms of rpm, the pre-programmed fast

idle speed (12,500 – 13,500 rpm) cannot be exceeded even if the H-needle is

screwed inwards. The risk in this case is still that the engine breaks down as a

result of a too lean fuel/air mix.

• At full throttle, the H-needle shall have a setting so that the engine is almost

splutters.