27

531 00 48-63

531 03 03-98

502 50 18-01

3

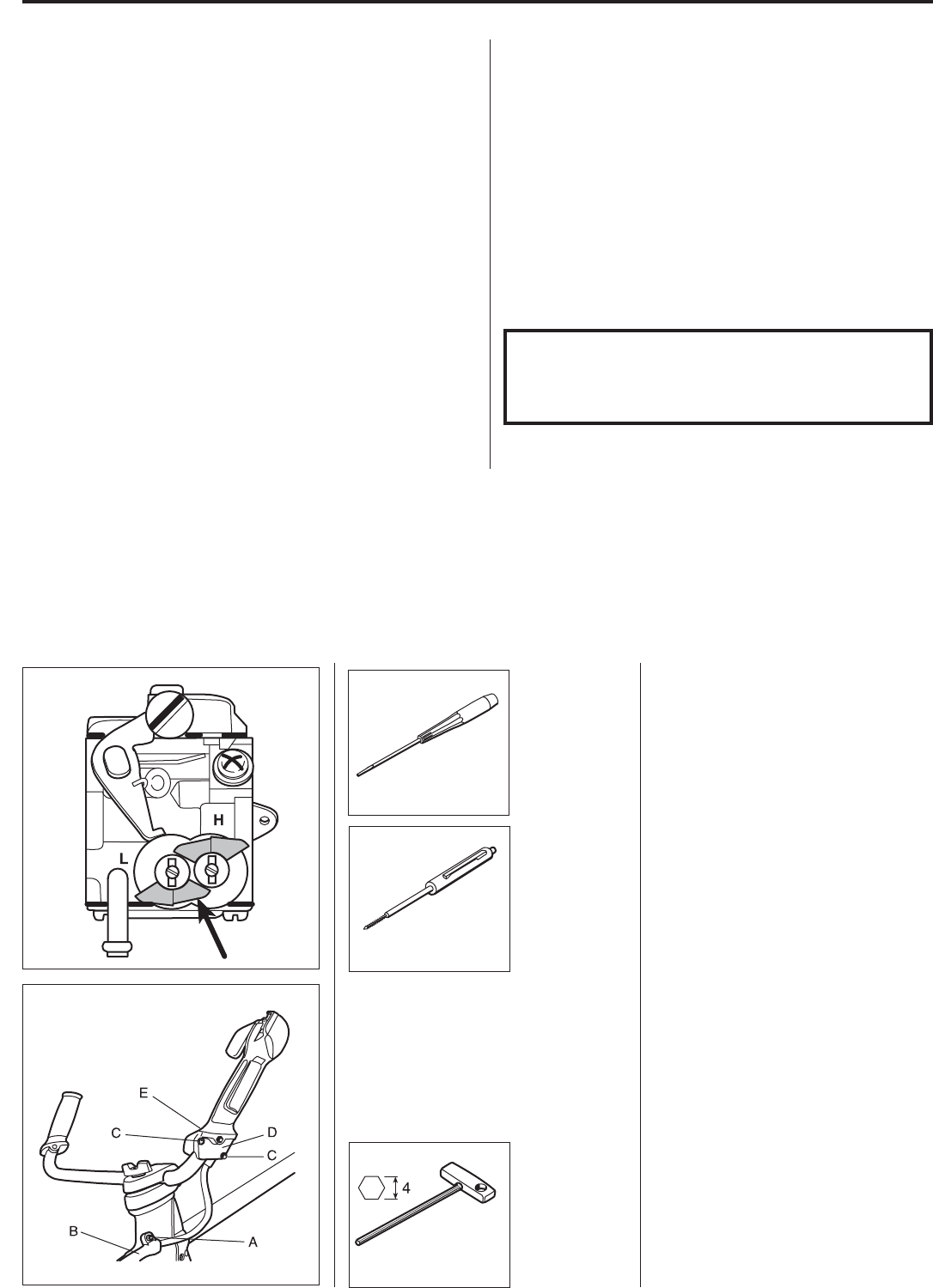

Carburettor needles with Zama “caps”.

Carburettor adjustment 345RX/FX

Adjusting the L-needle

1. Mount the Trimmy Fix (4 wires) and use 3.3 mm smooth

cord. The cord length should be 160 mm measured from the

end of the cord to the cord bushing on the trimmer head.

2. Run the engine warm for about 5 minutes.

3. Turn the L-needle so that the highest speed is attained.

4. If the speed exceeds 3,700 rpm, reduce it with the aid of the

idling speed’s T-screw (T) and a carry out a new adjustment

in accordance with point 3.

5. Then turn the L-needle anticlockwise so that the speed drops

by 300 rpm.

6. Then adjust the idling speed to 2,800 rpm by turning the T-

screw.

7. When mounting the plastic sleeve on the L-needle, the

needle is turned a quarter-turn anticlockwise once the

optimal setting has been made and the plastic sleeve is

mounted so that the needle cannot be turned anticlockwise.

Then turn the L-needle back a quarter-turn.

Carburettor adjustment 345RX/FX

Adjusting the H-needle

1. Mount the Trimmy Fix (4 wires) and use 3.3 mm smooth

cord. The cord length should be 160 mm measured from

the end of the cord to the cord bushing on the trimmer

head.

2. Run the engine warm for about 5 minutes.

3. Turn the H-needle so that the highest speed is attained.

4. Reduce the speed by 400 rpm by turning the H-needle

anticlockwise. Mount the plastic sleeve on the H-needle

so that it cannot be turned anticlockwise.

5. Then increase the speed by 200 rpm by turning the H-

needle clockwise.

Throttle

Disassemble the cable protector (B),

the cover (D) and the throttle from the

handle.

Remove the bolts and separate the two

halves of the throttle.

Throttle

Remove the bolt (A) and cable protec-

tor (B).

Remove the two bolts (C) and the cover

(D).

Remove the bolt (E) that attaches the

throttle to the handle and remove the

throttle.

Remove the bolts and separate the two

halves of the throttle.

Fuel system

NOTE!

If the cutting equipment rotates while idling the T-

screw should be turned anticlockwise until it stops

rotating.