45

6

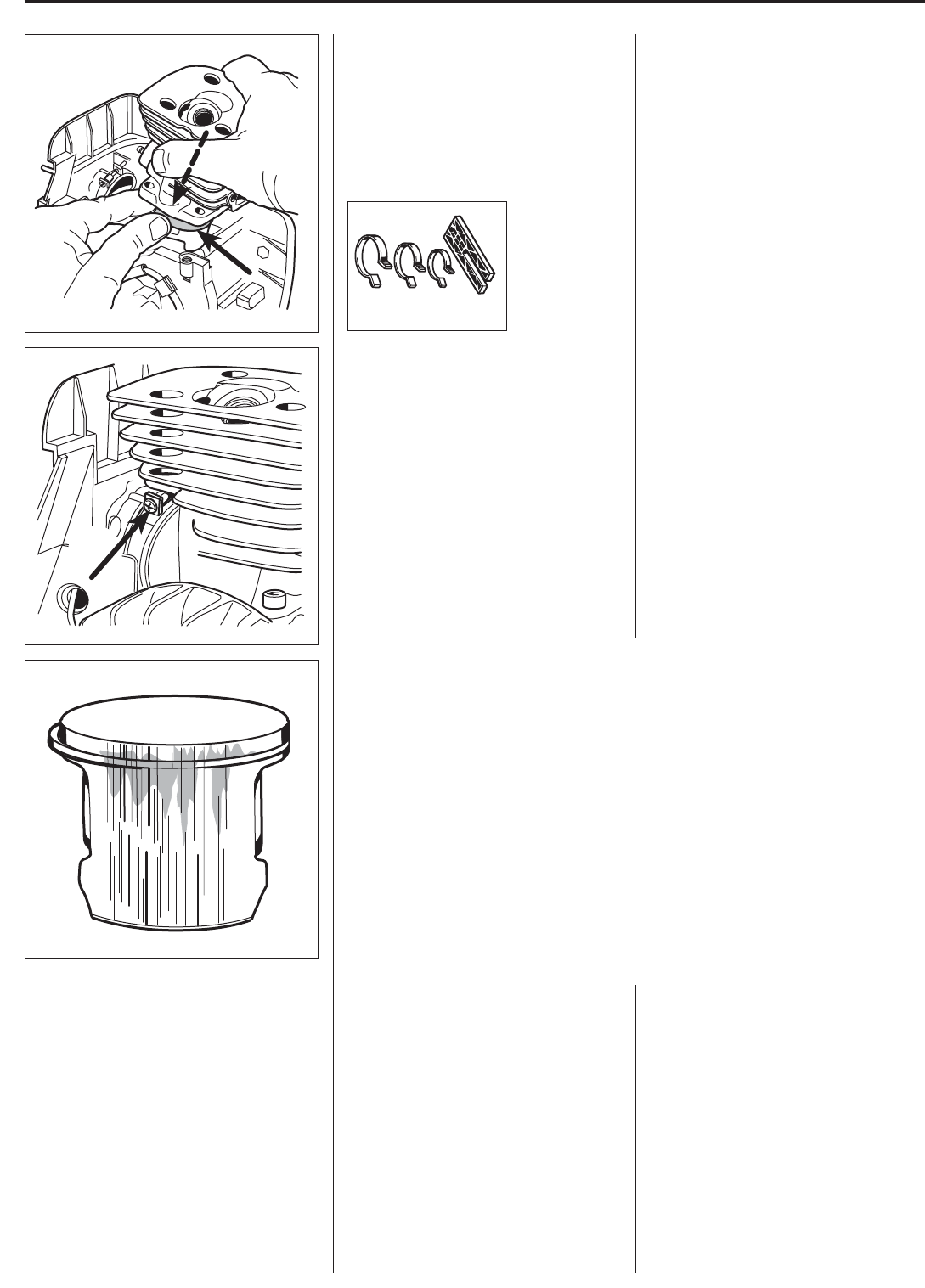

502 50 70-01

Cylinder and piston

Use a new gasket and fit the cylinder.

Make sure that the inlet manifold is

correctly connected to the sleeve

coupling on the cylinder and that the

impulse nipple sits right.

Place a new cylinder pedestal gasket

on the cylinder.

Lubricate the piston and the inlet

manifold on the cylinder with a few

drops of engine oil and fit the cylinder

using the smallest piston ring compres-

sor in assembly kit 502 50 70-01.

Make sure that the inlet manifold is

correctly connected to the sleeve

coupling on the cylinder and that the

impulse nipple sits right.

Screw the cylinder into place and

tighten the clamp around the inlet

manifold.

Assemble the other parts.

Screw the cylinder into place.

Tighten the clamp around the inlet

manifold.

Assemble the carburettor and the other

parts in the reverse order as set out for

dismantling.

Analysis and actions

Experience tells us that piston or cylinder failure due to manufacturing errors are

extremely rare.

The reason is usually due to other factors, which is evident from the following.

Note the reasons for the breakdown, repair the damage and take the actions

required to prevent the same thing happening again.

Small to medium size scores primarily in

the middle of the exhaust port.

Insufficient lubrication

The piston has small to medium size score marks usually in front of the exhaust

port. In extreme cases heat development can be so great that material from the

piston smears along the piston skirt and even in the cylinder bore.

Generally the piston ring is undamaged and moves freely in the ring groove

There can also be scores on the inlet side of the piston.

Cause:

• Incorrect carburettor setting.

Recommended max. speed ex-

ceeded.

• Incorrect oil mixture in the fuel.

• Too low octane fuel.

Action:

Check and change the carburettor

setting.

Change the fuel.

Change to a higher octane petrol.