MAINTENANCE

1900 07/11 Maintenance Section 5-12

©2011 Alamo Group Inc.

MAINTENANCE

Flail Blades Inspection

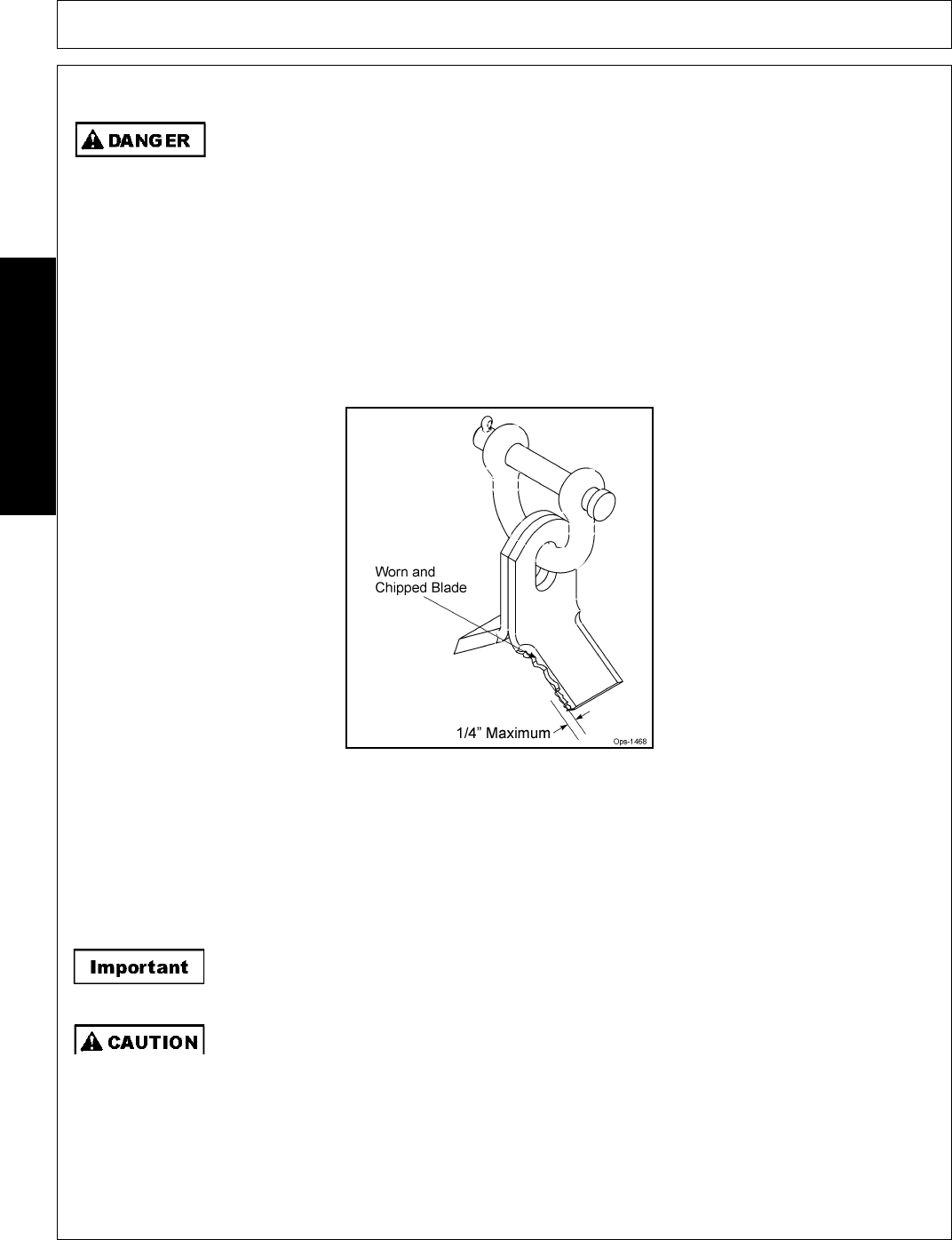

Inspect the Blades daily for abnormal wear. REPLACE ALL BLADES on the carrier

IMMEDIATELY if any blades have:

• Become bent or deformed from its original shape, or

• Wear inside the blade bolt hole, or

• Any cracks are visible, or

• Deep gouges in the blade’s surface are present, or

• Gouges or chipped areas in the cutting edge are larger than 1/4”(8mm), or

• The material on the leading edge has been worn away by more than 1/4”(8mm)

DO NOT straighten, sharpen, weld or hard-face blades

Failure to replace worn or damaged blades may lead to catastrophic failure of the blades and ejection of the

broken part with tremendous force which may cause serious bodily injury or death.

Always replace blades in sets

• Blades that are damaged may indicate severe service or abuse. If one blade is worn or damaged

other blades on the same shaft will have been subjected to the same severe service or abuse.

• The Flail rotor turns at speeds exceeding 2000 RPM and is dynamically balanced at the factory.

Differences in blade weight between used blades with loss of material from gouges or wear as

compared to new blades can cause severe vibration and damage to the Flail rotor. Always replace

blades as complete sets.

Use only genuine Rhino replacement blades and fasteners. Other blades and fasteners

may not meet the Rhino requirements and could fail during operation resulting in part being

thrown out from under the mower.

Never attempt to sharpen blades.

OPS-U-0046