MAINTENANCE

1900 07/11 Maintenance Section 5-9

©2011 Alamo Group Inc.

MAINTENANCE

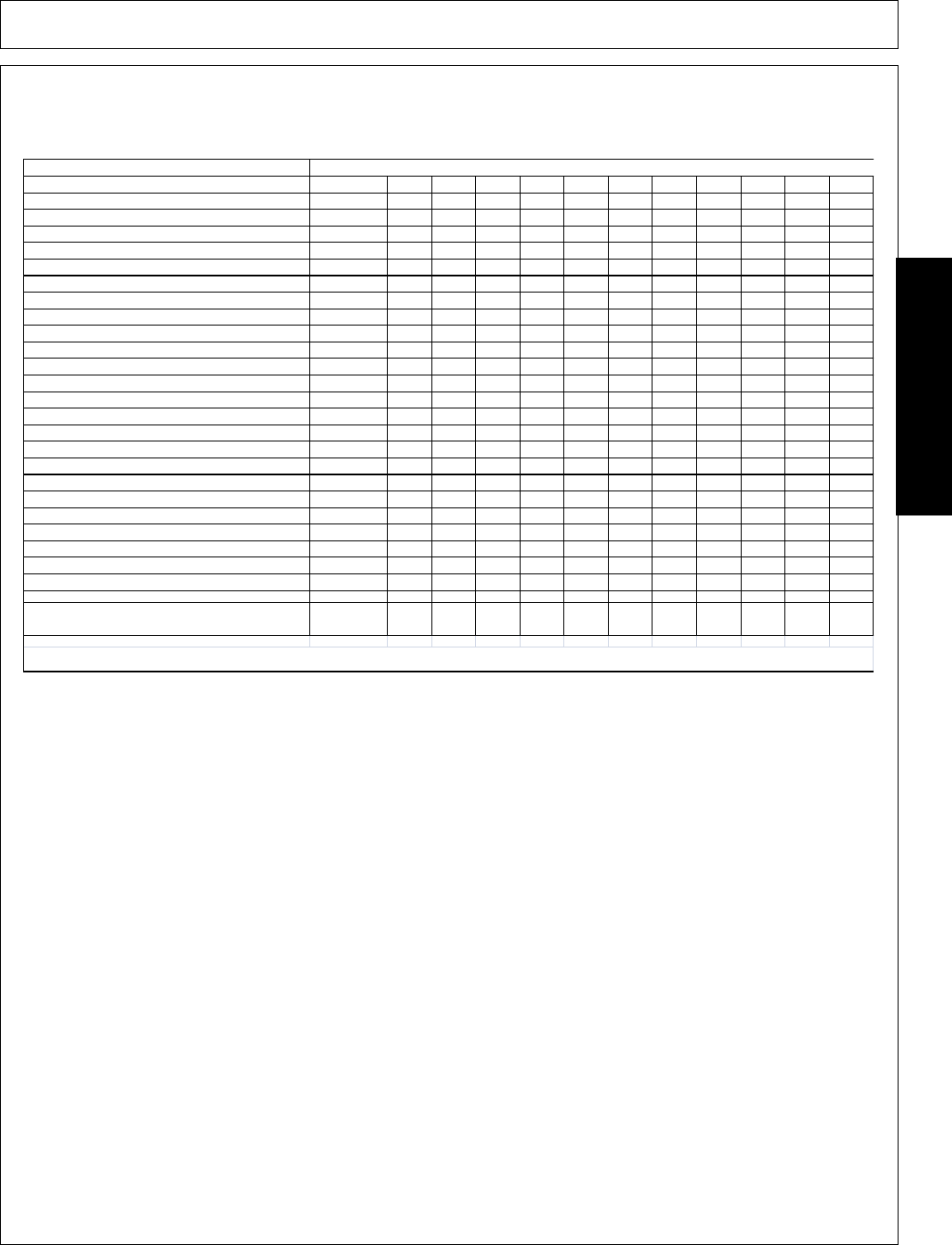

Hydraulic Component Maintenance Schedule

PROPER TORQUE FOR FASTENERS

The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to

this chart to determine the grade of bolts and the proper torque except when specific torque values are

assigned in manual text.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL*

NOTE:

These values apply to fasteners as received from supplier, dry or when lubricated with normal engine

oil. They do not apply if special graphitic or molydisulphide greases or other extreme pressure lubricants are

used. This applies to both UNF fine and UNC coarse threads.

Component Installation 200 400 600 800 1000 1200 1400 1600 1800 2000 2200

Pump Drive Shaft Check and Lubricate

X XXXXXXXXXXX

Pump Mounting Bolt torque check (Inspect Daily)

X XXXXXXXXXXX

Charge Pump Filter

Installation

XX X

Pressure Filter to the Control Valve

Installation

XX X

Return Canister Filter Element

Installation

XX X

Hydraulic Oil Change

Installation

X X

Hydraulic Oil Particle Count Testing XX X X

Hydraulic Tank Breather Filter

Installation Inspect Replace

Hydraulic Tank Suction Screen

Installation Inspect Inspect

Hydraulic Hose Inspection/Replacement

Installation Inspect Inspect Inspect Inspect Inspect Inspect Inspect Inspect Inspect Inspect Inspect

Cooling Fan Clean and Inspect

Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily

Check Hydraulic Fluid Level (Inspect Daily)

Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily

Mower Blades Replace (INSPECT DAILY) XXXXXXXXXXX

Blade Bolts Replace (INSPECT DAILY) XXXXXXXXXXX

Blade Bar Assembly Replace

Installation

XX

Spindle Lube Replacement (INSPECT DAILY)

XXX

Spindle Bearing Pre-load Inspection X XXXXXXXXXXX

Mower Debris Guard Inspect/Replace X XXXXXXXXXXX

Pivot Point Lubrication

Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily Daily

King Pin Bearing Replacement

Installation

X

Pivot Pin Bearing replacement (Steel)

Installation

X

Pivot Pin Bearing Replacement (Fiber)

Installation

XX

Inspect Operation And Safety Decals Replace

when faded, torn or missing.

X XXXXXXXXXXX

Repeat the Maintenance Schedule based on the hours indicated for the life of the machine

Hours of Operation