14 Dealer Service

32695 (Rev. 11/17/2006)

DEALER SERVICE

■ Lower mower to ground, turn tractor engine off

and remove ignition key before performing any

maintenance.

■ When completing a maintenance or service

function, make sure all safety shields are in good

condition and installed before placing mower in

service.

■ Always use personal protection devices such

as eye and ear protection when performing mainte-

nance functions.

The information in this section is written for dealer ser-

vice personnel. The repair described herein requires

special skills and tools. If your shop is not properly

equipped or your mechanics are not properly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

SPINDLE INSPECTION

Spindles are equipped with two tapered roller bearings.

Adjustment is set by pressing a sleeve on the shaft

until all end play is removed. Adjustment is maintained

with a roll pin driven through the sleeve and shaft.

Periodically inspect blade spindles by grasping pulley,

moving from side to side and up and down. Also rotate

spindle. If end play or wobble is detected or if it feels

rough when rotated (indicating bad bearings), repair or

replace.

REMOVING SPINDLE FROM MOWER

Remove blade from spindle. Refer to Blade Removal

on page 12.

Remove belt shield and remove belt.

Disassemble split taper bushing (located on top of pul-

ley) by removing the two bolts and inserting them into

threaded holes. Tighten alternately to remove split

taper bushing.

Remove key and pulley.

Remove four spindle attaching bolts and remove spin-

dle.

SPINDLE REPAIR

Permatex 3D Aviation Form-A-Gasket

®

, or equivalent,

is recommended as a sealant.

For reference, the short cup chamber is on top.

Cups and cones are a press fit to minimize wear.

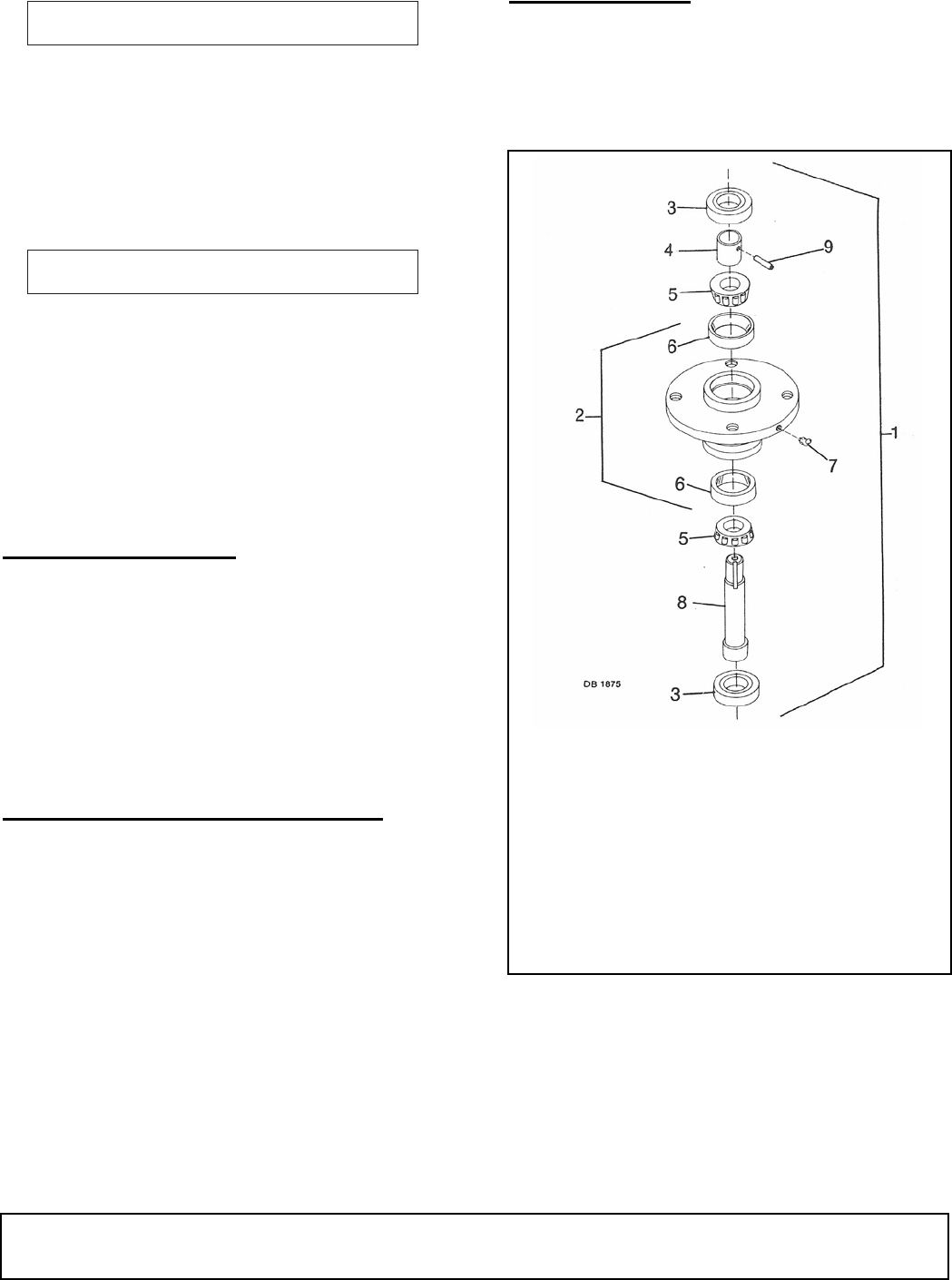

Figure 7. Spindle Repair

Disassembly

Drive roll pin out of sleeve and shaft.

Place spindle assembly in a press and press shaft

down through housing.

Remove seals from housing.

A WARNING

A CAUTION

1. Blade Spindle Assembly

2. Spindle Housing and Cups

3. Seal

4. Sleeve

5. Bearing Cone

6. Bearing Cup

7. Grease Fitting

8. Spindle Shaft

9. Roll Pin