24 Dealer Service

MAN0646 (Rev. 11/5/2007)

7. Start engine and disengage parking brake.

8. Open pump dump valve.

9. Slowly push steering levers back and forth 5 to 6

times to bleed the hydraulic system.

10. Close pump dump valve.

11. Adjust NEUTRAL position of steering linkage as

necessary.

12. Stop engine. Check level of hydraulic reservoir and

check for leaks.

13. Remove power unit from stands.

PTO BELT REMOVAL

1. Remove key from switch.

2. Remove belt shield, if necessary

3. Remove clutch anti-rotation cable, if necessary.

4. Loosen idler spring bolt (J-bolt), and derail belts

from pulleys.

5. Remove belts.

ENGINE REMOVAL

1. Disconnect throttle cable, battery cables, hoses,

fuel line, and electrical wires from engine.

2. Remove the four engine mounting bolts from

bottom of power unit frame.

3. Remove belts from the front and rear engine

pulleys. See belt removal.

4. Lift engine from the power unit frame.

NOTE: Contact your authorized engine dealer for

parts and repairs.

PARKING BRAKE ADJUSTMENT

NOTICE

■ Overtightening the brake can cause internal

damage to the brake linkage.

NOTE: Adjust right and left brakes individually.

1. Disconnect clevis from right parking brake and

brake handle linkages.

2. Adjust left parking brake pull rod until brake rock

shaft lug is perpendicular with the bottom edge of

the frame rail.

3. Readjust and reconnect clevis for parking brake

handle linkage.

NOTE: Approximately 12 to 13 lbs of force at the

top of the handle is needed to apply the single

brake.

4. Reconnect right parking brake rod.

5. Disconnect clevis from left parking brake and brake

handle linkages.

6. Adjust right parking brake pull rod until brake rock

shaft lug is perpendicular with the bottom edge of

the frame rail.

7. Reconnect parking brake rod.

NOTE: Approximately 24 to 26 lbs of force at the

top of the handle is needed to apply both brakes.

SOLENOID TEST

1. Disconnect solenoid from engine and briefly crank

engine.

2. Leave key ON. Fuel solenoid should be engaged

(pushed out).

NOTE: If fuel solenoid will not engage, check inline

fuse. If fuse is OK, test the solenoid in this manner:

a. Disconnect wires from solenoid terminals.

b. Set a multi meter to X 1 ohm scale.

c. Connect leads to “Common” and “Pull” solenoid

terminals; meter should indicate 0.1 ohms.

d. Connect leads to “Common” and “Hold” sole-

noid terminals; meter should indicate 10 ohms.

NOTE: If you do not get these readings, or one of

the circuits reads “OPEN”, then the solenoid is

defective and you will need to replace the defective

solenoid.

CLUTCH REPAIR

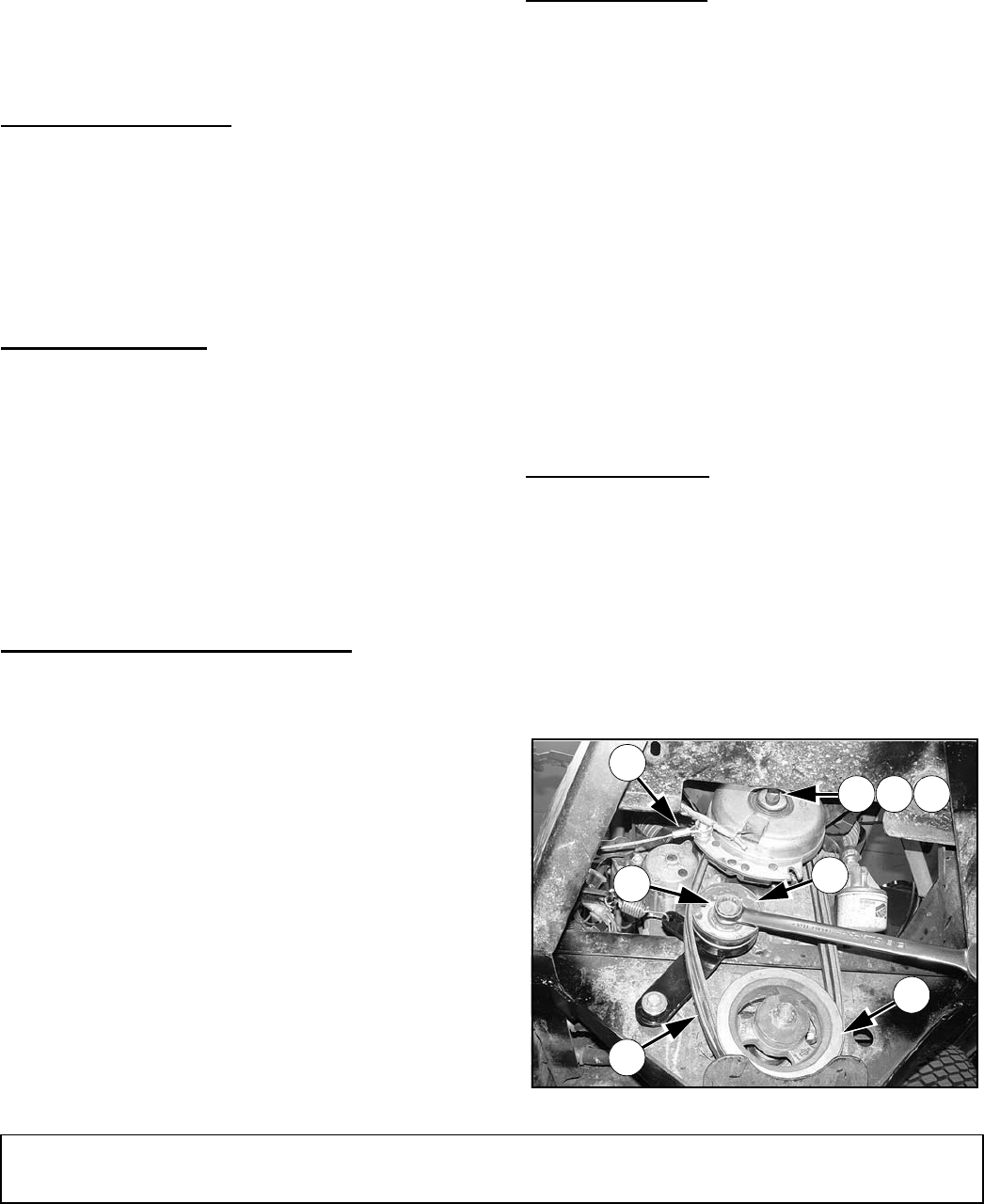

Remove Components (Figure 14 & Figure 15)

1. Position Mow’n Machine on a level work area.

2. Set parking brake, stop engine, and remove key.

NOTE: Photo in Figure 14 was taken from underneath

the power unit for clarification. All work can be per-

formed from above.

NOTE: It may be easier to rework clutch if you first

remove counterweights from the rear of the power unit.

Figure 14. Clutch and Sheave Assembly

47

22

16

21 8 20

2

6

DP9