12 Operation

MAN0646 (7/6/2007)

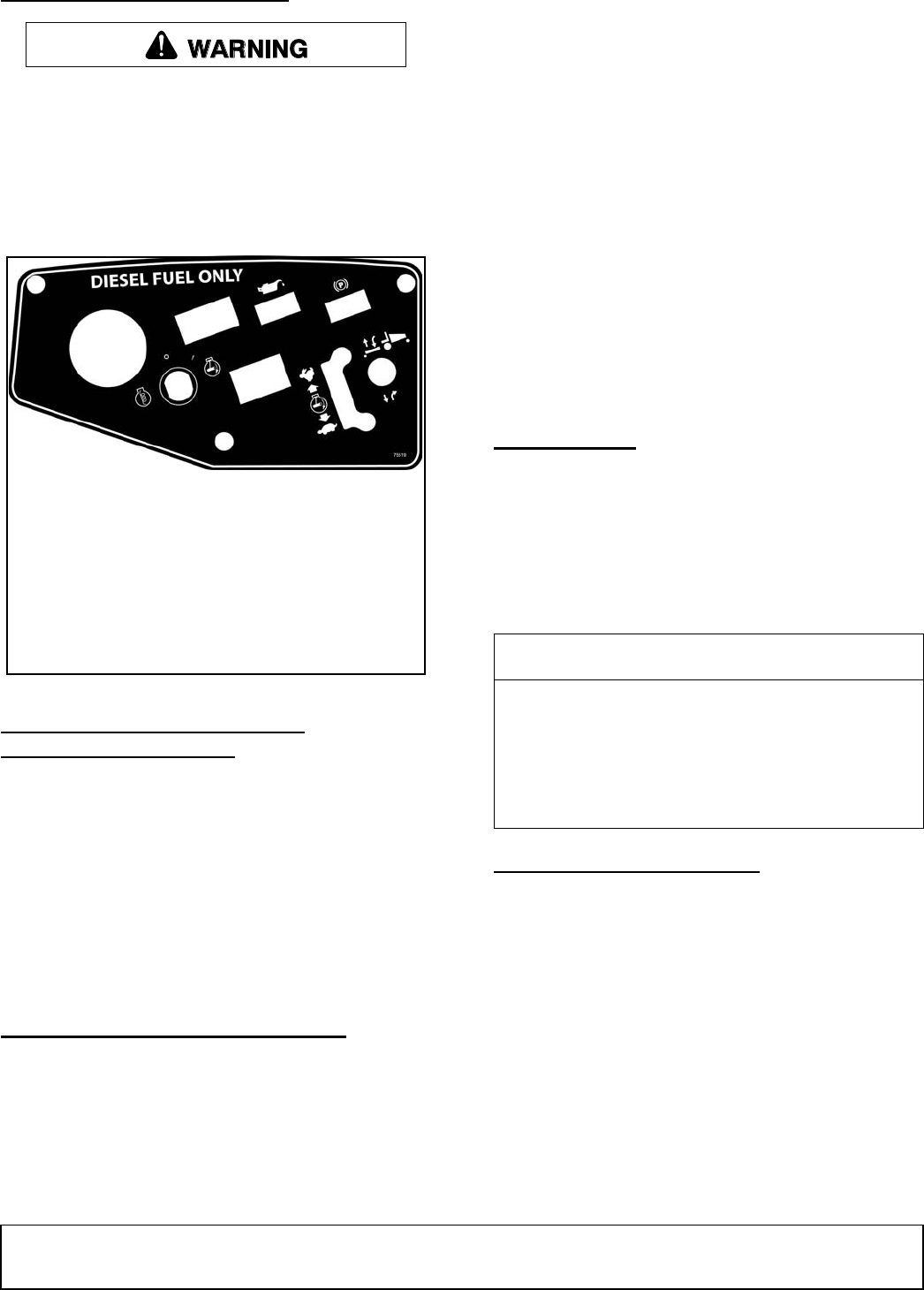

CONTROLS AND SWITCHES

Know your controls and how to stop engine and

attachment quickly in an emergency.

Control and indicator console is located on the right

fuel tank. This console contains controls needed to

operate this unit. PTO switch (2) is used to engage

attachments: pull up to engage, push down to disen-

gage.

Figure 1. Console Control Locations

DECK HEIGHT/POWER TILT™

ADJUSTMENT SWITCH

The deck height and Power Tilt™ switch is used with

MXT or MX deck equipped with the Power Tilt™ Kit.

Push the toggle switch forward to raise the deck and

pull back to lower the deck to the desired cutting

height. For Power Tilt™ operation, pull back and hold

the toggle switch to lower the deck and cycle through to

the tilt position. Release switch when deck reaches

maximum tilt position. To lower the deck, push and hold

toggle switch until it cycles to the desired cutting

height. NOTE: Power Tilt™ feature must not be used

when sitting in the seat.

BRAKE & TEMPERATURE LIGHTS

Brake Light

NOTICE

■ Do not operate with parking brake engaged or

damage to the brake adjustment will occur.

The brake light indicates when the brake is engaged.

To ensure light is operating properly, engage parking

brake and turn ignition key switch to the “ON” position.

Control panel brake light (3) should be on.

Temperature Light

NOTICE

■ For overheating, clean radiator grill and check

engine coolant level.

The temperature light will alert you when the engine

temperature is excessive. The temperature light sys-

tem is not intended to shut the engine off or prevent

operation; it is designed to provide notification. If tem-

perature light starts to flash during operation, discon-

tinue operation. The light is programed to flash at 220°

fahrenheit and above.

NOTE: The radiator and prescreen require regular

cleaning to prevent engine overheating. Clean the pre-

screen daily and the radiator fins every 40 hours. Do

not use high pressure on radiator fins to avoid radiator

damage.

HOUR METER

The hour meter is programed to alert the operator at

various service intervals. The change oil light will flash

at 20 hours (initial break in) and every 100 hours after.

The light will flash for a period of 4 hours (alternating

between hours & change oil) and than resume normal

mode. The hour glass will flash every second indicating

it’s in running mode.

SAFETY SWITCH SYSTEM

Several safety switches are incorporated in the unit’s

design to prevent it from being started out of NEUTRAL

(handles pivoted outward) or with PTO engaged.

The PTO control must be in the “OFF” position and the

steering handles in the NEUTRAL position before unit

can be started.

A safety switch behind the operator’s seat will cause

the engine to stop if the operator leaves the seat with

the PTO or steering handles engaged. The engine will

also stop if the steering handles are moved from NEU-

TRAL while the parking brake is engaged. It will not run

if the deck jumper wire (for Power Tilt™ operation) is

not connected to the wire harness or the deck safety

switch is disengaged.

1. Temperature gauge

2. PTO switch

3. Brake light

4. Oil light

5. Ignition switch

6. Hour meter

7. Throttle control

8. Deck height switch

1

2

3

4

5

6

7

8

Service Intervals

20 hrs Engine oil change (break in)

100 hrs Engine oil change & filter

500 hrs Hydraulic oil change & filter (see

hydraulic transmission - change oil

& filter, page 19)

(Rev. 1/7/2010)