Incorrectcable adjustment could cause

the wheels andtines to rotate unexpect-

edly. Follow adjustment procedures

carefully. Failure to do so could result

in personalinjuryorpropertydamage.

4. Checkfor correct spring/cable tension

as instructed in Section5, Checkingand

Adjusting ForwardClutch Belt Tension.

5. When tension is correct, tighten the

two jam nuts (B) securely.

STEP5: CHECKTRANSMISSION

GEAROIL LEVEL

Thetransmission was filled with gear oil

at the factory. However,be sureto check

the oil levelat this time to makecertain it

iscorrect.

IMPORTANT:Do not operatethe tiller if

the gear oil level is low. Doingso will

result in severedamageto the transmis-

sion components.

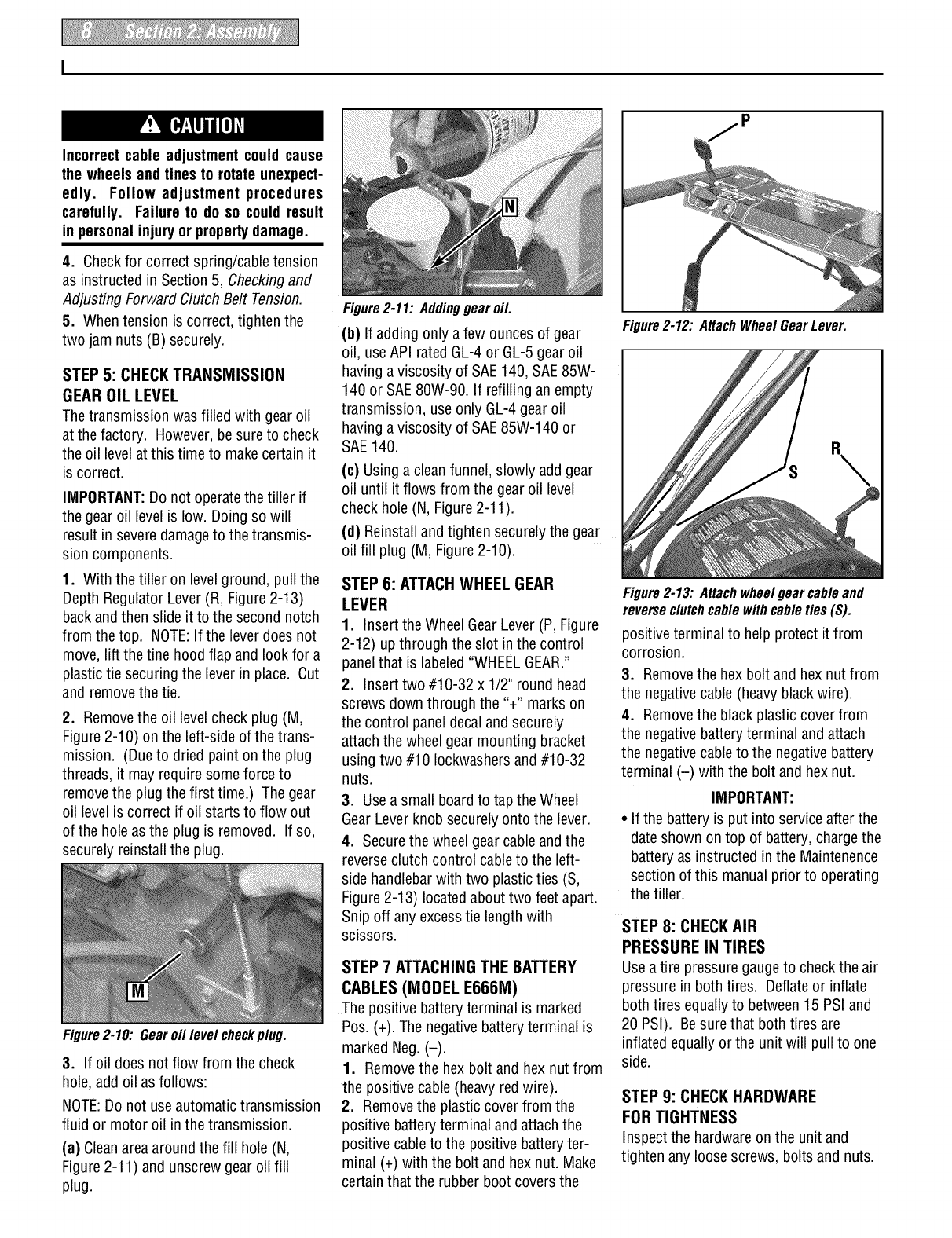

1. With the tiller on levelground, pull the

Depth Regulator Lever (R, Figure2-13)

backand then slide it to the second notch

from the top. NOTE:If the leverdoes not

move,lift the tine hoodflap and look for a

plastictie securing the leverin place. Cut

and removethe tie.

2. Removethe oil levelcheck plug (M,

Figure2-10) on the left-side of the trans-

mission. (Dueto dried painton the plug

threads, it may require someforce to

removethe plug the first time.) The gear

oil levelis correct if oil starts to flow out

ofthe hole asthe plug is removed. If so,

securely reinstall the plug.

Figure2-10: Gearoil level checkplug.

3. If oil does notflow from the check

hole,add oil asfollows:

NOTE:Donot useautomatic transmission

fluid or motor oil in the transmission.

(a) Cleanareaaround the fill hole (N,

Figure2-11) and unscrewgear oil fill

plug.

Figure2-11: Addinggearoil.

(b) If adding only a few ouncesof gear

oil, useAPI ratedGL-4 or GL-5 gear oil

havinga viscosity of SAE140, SAE85W-

140 or SAE80W-90. If refilling an empty

transmission, useonly GL-4 gearoil

havinga viscosity of SAE85W-140 or

SAE140.

(c) Usinga cleanfunnel, slowly addgear

oil until it flows from the gear oil level

check hole (N, Figure2-11).

(d) Reinstalland tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP 6: ATTACHWHEEL GEAR

LEVER

1. Insert the WheelGearLever(P, Figure

2-12) up through the slot in the control

panelthat is labeled"WHEELGEAR."

2. Insert two #10-32 x 1/2" round head

screws down through the "+" marks on

the control paneldecaland securely

attach thewheel gear mounting bracket

usingtwo #10 Iockwashersand #10-32

nuts.

3. Usea small board to tap the Wheel

GearLeverknobsecurely onto the lever.

4. Securethe wheelgear cableand the

reverseclutch control cableto the left-

side handlebarwith two plasticties (S,

Figure2-13) locatedabout two feet apart.

Snip off anyexcesstie length with

scissors.

STEP7 ATTACHINGTHE BATTERY

CABLES(MODEL E666M)

The positive batteryterminal is marked

Pos. (+). Thenegative batteryterminal is

marked Neg.(-).

1. Removethe hex bolt and hex nut from

the positive cable(heavy red wire).

2. Removethe plasticcover from the

positive batteryterminal and attachthe

positive cableto the positive batteryter-

minal (+) with the bolt and hex nut. Make

certain that the rubber boot coversthe

Figure2-12: AttachWheel GearLever.

Figure2-13: Attachwheel gear cableand

reverseclutchcable with cableties(S).

positive terminal to help protect itfrom

corrosion.

3. Removethe hexbolt and hexnut from

the negativecable(heavy blackwire).

4. Removethe black plastic cover from

the negativebatteryterminal and attach

the negativecableto the negativebattery

terminal (-) with the bolt and hex nut.

IMPORTANT:

• If the battery is put into serviceafter the

dateshown on top of battery, chargethe

batteryas instructed in the Maintenence

sectionof this manual prior to operating

the tiller.

STEP 8: CHECKAIR

PRESSURE IN TIRES

Usea tire pressuregaugeto check the air

pressure in bothtires. Deflateor inflate

both tires equallyto between15 PSI and

20 PSI). Besure that both tires are

inflated equally or the unit will pull to one

side.

STEP 9: CHECK HARDWARE

FOR TIGHTNESS

Inspect the hardwareon the unit and

tighten anyloose screws, bolts and nuts.