2 Assembly

To prevent personal injury or property

damage,do notstartthe engine until all

assembly steps are complete and you

havereadand understandthe safetyand

operatinginstructionsin this Manual.

INTRODUCTION

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginningassembly.

INSPECTUNIT

Inspectthe unit andcarton for damage

immediatelyafter delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them ofthe

damageand request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 days afterthe unit has

beendelivered.Contact usat the factory if

you needassistancein this matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeanycardboard inserts and

packagingmaterialfrom the carton.

Removeanystaples from the bottom of

the carton and removethe carton.

2. Cutthe large,plastic tie strap that

securesthe transmission tubeto the ship-

ping pallet. Leavethe handlebarson top

of the tiller to avoid damaginganycables.

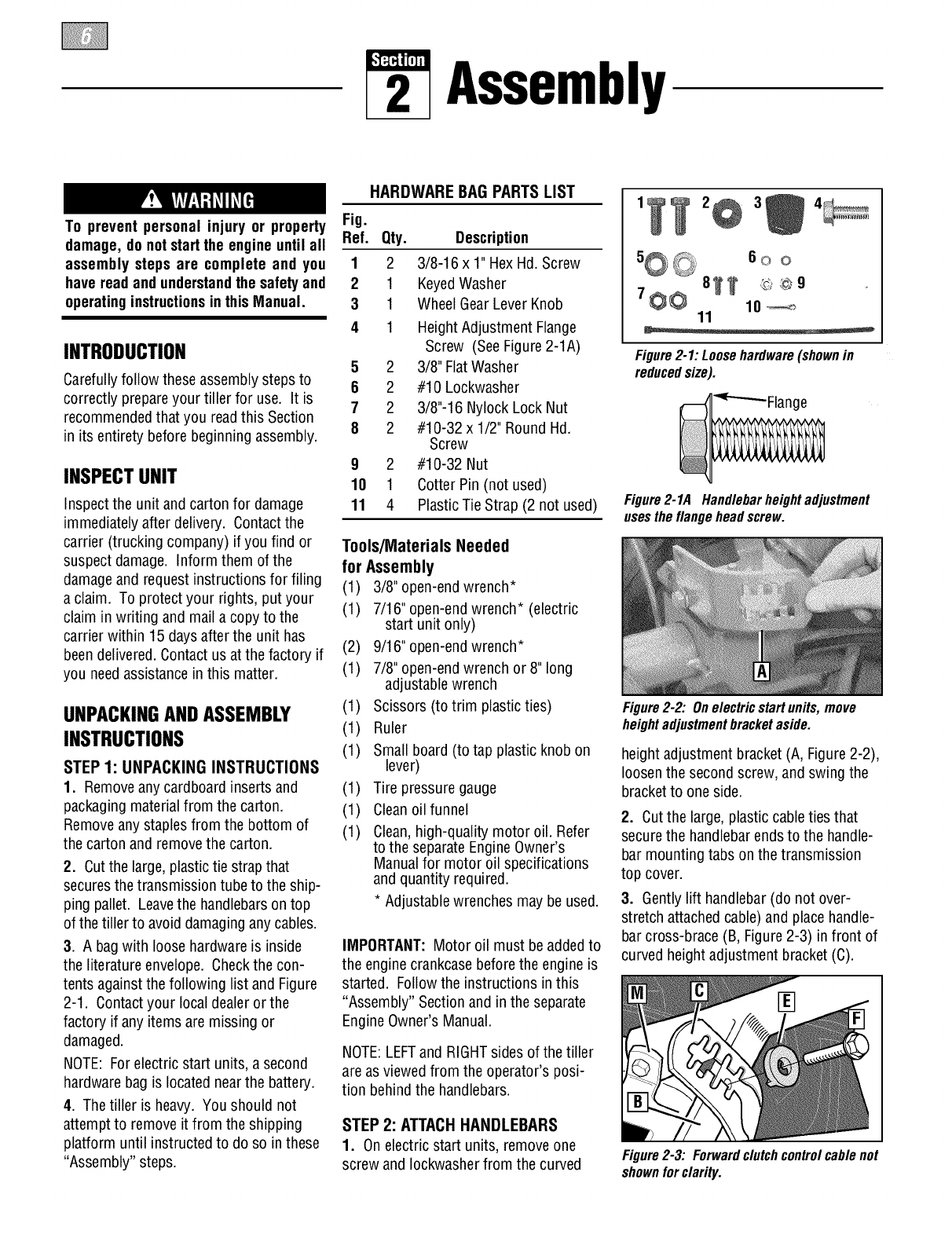

3. A bag with loose hardwareis inside

the literature envelope. Checkthe con-

tents against thefollowing list and Figure

2-1. Contactyour local dealeror the

factory if any items are missing or

damaged.

NOTE:For electric start units, a second

hardwarebag is located nearthe battery.

4. Thetiller is heavy. You should not

attempt to remove it from the shipping

platform until instructed to do so in these

"Assembly" steps.

HARDWARE BAG PARTS LIST

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1" HexHd. Screw

2 1 KeyedWasher

3 1 WheelGearLeverKnob

4 1 Height Adjustment Flange

Screw (SeeFigure2-1A)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" RoundHd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 PlasticTie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8" open-endwrench*

(1) 7/16" open-endwrench* (electric

start unit only)

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench or 8" long

adjustable wrench

(1) Scissors (to trim plasticties)

(1) Ruler

(1) Small board (to tap plastic knob on

lever)

(1) Tire pressuregauge

(1) Cleanoilfunnel

(1) Clean,high-quality motor oil. Refer

to the separateEngineOwner's

Manualfor motor oil specifications

and quantity required.

* Adjustablewrenches may be used.

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebeforethe engine is

started. Followthe instructions in this

"Assembly" Sectionand in the separate

EngineOwner's Manual.

NOTE:LEFTand RIGHTsides of thetiller

are asviewedfrom the operator's posi-

tion behindthe handlebars.

STEP 2: ATTACHHANDLEBARS

1. On electric start units, removeone

screw and Iockwasherfrom thecurved

5@_, 60 o

8_ @©9

7_ 10_

11

Figure2-1:Loosehardware(shownin

reducedsize).

Figure2-1A Handlebarheightadjustment

usestheflangeheadscrew.

Figure2-2: Onelectric startunits, move

heightadjustmentbracket aside.

heightadjustment bracket (A, Figure2-2),

loosenthe secondscrew, and swing the

bracketto one side.

2. Cutthe large,plastic cableties that

securethe handlebarends to the handle-

bar mounting tabs on the transmission

top cover.

3. Gently lift handlebar (do not over-

stretch attachedcable) and place handle-

bar cross-brace (B, Figure 2-3) in front of

curved heightadjustment bracket (C).

Figure2-3: Forwardclutchcontrolcablenot

shownforclarity.