I

Ir!lv_vl._!:t_ll_[fll

t

q

b

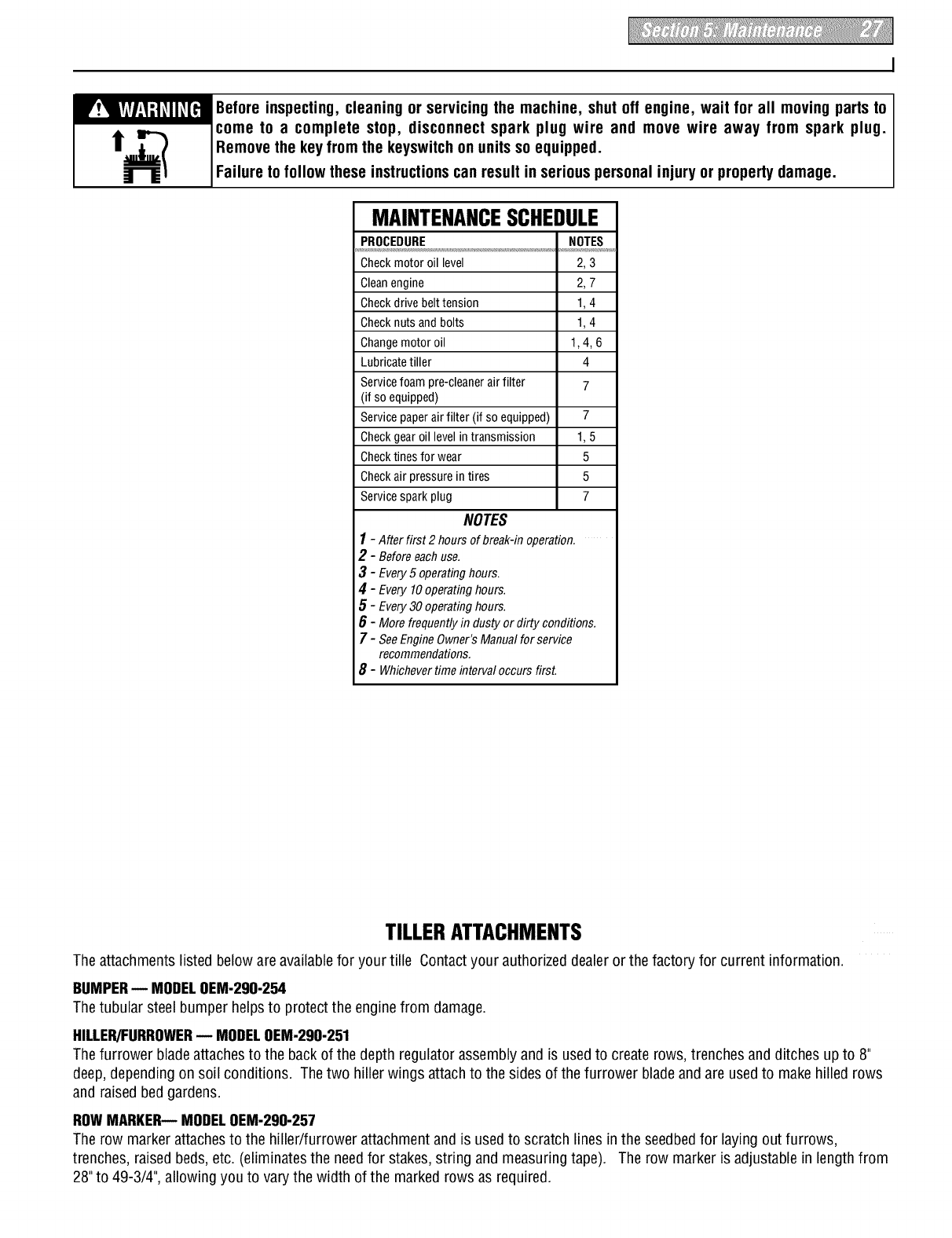

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Removethe key fromthe keyswitchon units so equipped.

Failure tofollow these instructions canresult in seriouspersonal injury or propertydamage.

MAINTENANCESCHEDULE

PROCEDURE NOTES

Check motor oil level 2, 3

Clean engine 2, 7

Check drive belt tension 1, 4

Checknutsandbolts 1,4

Changemotor oil 1,4, 6

Lubricatetiller 4

Service foam pre-cleaner air filter 7

(if so equipped)

Service paperair filter (if so equipped) 7

Check gearoil levelin transmission 1, 5

Checktines for wear 5

Check air pressurein tires 5

Service spark plug 7

NOTES

1 - After first 2 hours of break-in operation.

2 - Before eachuse.

3 - Every5 operating hours.

4 - Every 10operating hours.

5 - Every30 operating hours.

6 - More frequently in dusty or dirty conditions.

7 - SeeEngine Owner's Manual for service

recommendations.

8 - Whichevertime interval occurs first.

TILLERATTACHMENTS

Theattachments listed beloware availablefor your tille Contactyour authorized dealeror the factory for current information.

BUMPER-- MODEL0EM-290-254

Thetubular steel bumper helpsto protect the enginefrom damage.

HILLER/FURROWER-- MODEL0EM-290-251

Thefurrower bladeattachesto the backof the depth regulator assemblyand is usedto create rows, trenches and ditches upto 8"

deep,depending on soil conditions. The two hiller wings attachto the sides of the furrower bladeand are usedto makehilled rows

and raisedbedgardens.

ROWMARKER--MODEL0EM-290-257

The row marker attachesto the hiller/furrower attachmentand is used to scratch linesin the seedbedfor layingout furrows,

trenches, raised beds,etc. (eliminatesthe needfor stakes,string and measuringtape). The row marker is adjustablein lengthfrom

28" to 49-3/4", allowing you to varythe width of the marked rows as required.