I

t

q

b

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Removethe key fromthe keyswitchon units so equipped.

Failure tofollow these instructions canresult in seriouspersonal injury or propertydamage.

Figure5-6: Removingsingle tine.

Figure5-7: Removingatineassembly.

Figure5-8: Forwardclutchbelt. (C, Left-

side view, nobelt cover.)

Followthe belt adjustment instructions

carefully. An incorrectadjustmentcould

result in the clutch control mechanism

engaging too soon. This could cause

loss of tiller control and result in per-

sonalinjuryor propertydamage.

CHECKINGAND ADJUSTING

TENSION ON CLUTCH BELTS

Maintaining correct belt tension is impor-

tant to good tilling performanceand long

belt life. A loosebelt will slip on the

engine andtransmission pulleysand

causethe tines andwheels to slow down

- orstop - eventhough theengine is

running at full speed. A loose beltwill

also result in premature beltwear.

While checking belttension, also check

for cracks,cuts or frayed edges.A belt in

poor condition should be replaced.

Tension on a newforward clutch belt (C,

Figure5-8) should becheckedafter the

Figure5-9: Reverse clutchbelt(D).

(Right-side view,nobelt cover.)

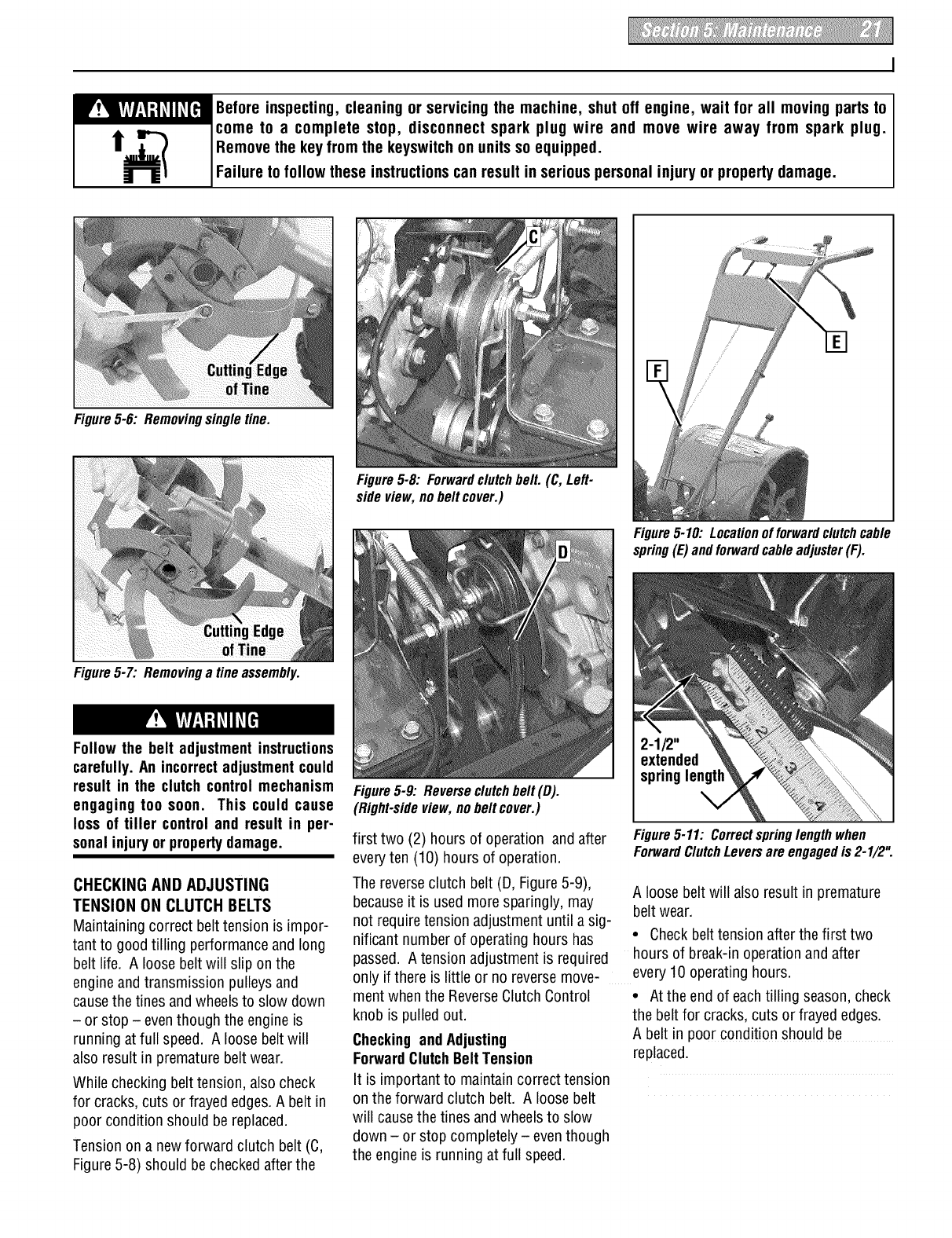

Figure5-10: Locationofforwardclutchcable

spring(E)andforwardcableadjuster(F).

2-1/2"

first two (2) hours of operation and after

every ten (10) hours of operation.

Figure5-11: Correctspringlengthwhen

ForwardClutchLeversareengagedis2-1/2".

The reverseclutch belt (D, Figure5-9), A loose beltwill also result in premature

becauseit is used moresparingly, may belt wear.

not require tension adjustment until a sig-

nificant number of operating hours has • Checkbelttension after thefirst two

passed. A tension adjustment is required hours of break-inoperation and after

only if there is little or no reversemove- every 10 operating hours.

ment whenthe ReverseClutchControl

knob is pulled out.

CheckingandAdjusting

ForwardClutchBelt Tension

It is important to maintain correct tension

on theforward clutch belt. A loosebelt

will causethe tines andwheels to slow

down- or stop completely - even though

the engine is running atfull speed.

• Atthe end of eachtilling season,check

the beltfor cracks, cuts or frayededges.

A belt in poor condition should be

replaced.