Before inspecting, cleaning or servicing the machine, shutoff engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove the keyfrom the keyswitch on unitsso equipped.

Failure to follow these instructionscan result in serious personal injury or property damage.

WHEELGEARCABLEADJUSTMENT OFFSEASONSTORAGE

When the WheelGearLeveris in DISEN-

GAGE,the wheels will roll freely (free-

wheel). Thewheels should not roll freely

whenthe lever is in ENGAGE.If the

wheels roll freely whenthe Wheel Gear

Leveris in ENGAGE,the wheel gearcable

needsto be adjustedas described below.

1. With the engineshut off and the spark

plug wire disconnected, put the Wheel

GearLeverin ENGAGE.

2. Loosenthe top adjustment nut (A,

Figure5-4) on the wheelgear cable

bracketthat is located on the left side rear

of thetransmission.

3. Pushthe wheel gearcable (B) down

and roll thetiller slightly forward or back-

ward until the eccentric lever (C)engages

(locks) the wheels. Holdthe cable in that

position andtighten the top (A) and

bottom (D) adjustment nuts.

4. Movethe WheelGear Leverto

ENGAGEand DISENGAGEseveraltimes

to checkthe adjustment. Thewheels

should not roll when the leveris in

ENGAGE,but they should roll whenthe

leveris in DISENGAGE.Readjustthe

cableasrequired.

C

Figure5-4: Wheelgear cableassembly.

Whenthe tiller won't beusedfor

extended periods, prepare it for storage

asfollows:

1. Cleanthe tiller and engine.

2. Do routine tiller lubrication and check

for loose parts and hardware.

3. Protect the engineand perform recom-

mendedengine maintenancebyfollowing

the engine storage instructions found in

the separateEngineOwner's Manual.

NOTE:Besureto protectthe fuel lines,

carburetor andfuel tank from gum

deposits by removing fuel or by treating

fuel with a fuel stabilizer (follow engine

manufacturer's recommendations).

4. On electric start units, follow "Battery

Storage" instructions in this Section.

5. Store unit in a clean,dry area.

6. Neverstore thetiller with fuel in the

fuel tank in an enclosedarea wheregas

fumes could reachan openflame or

spark, or where ignition sources are

present (spaceheaters,hot water heaters,

furnaces, etc.).

BOLOTINES

Thetines will wear with useand should

be inspectedat the beginning of each

tilling season andafter every30 operating

hours. Tines can be replaced individually

or as acomplete set. Neverinspector

servicethe tines unlessthe engine is

stopped, the spark plug wire is discon-

nected,and the ignition key is removed

on electric start models.

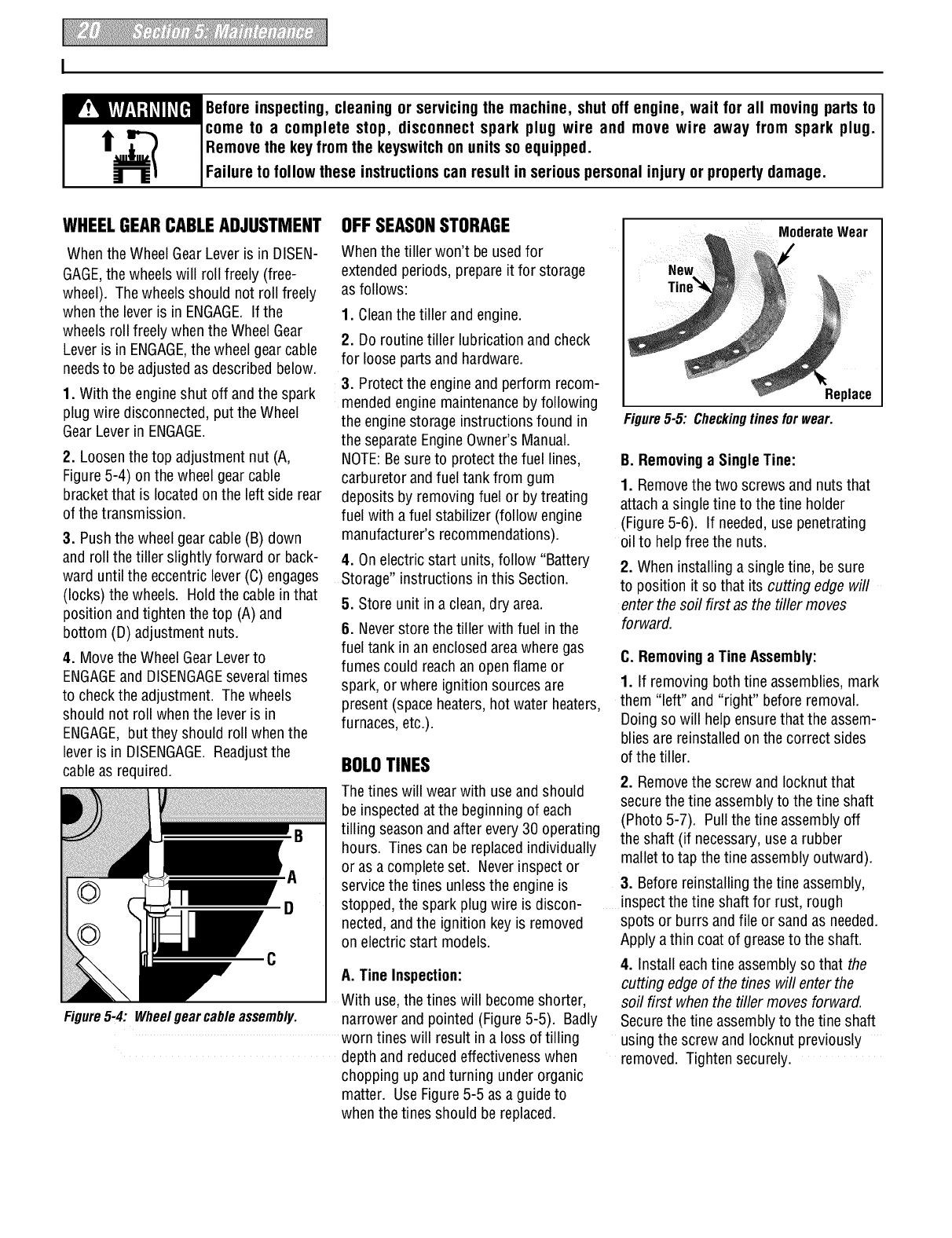

A. Tine Inspection:

With use,thetines will becomeshorter,

narrowerand pointed (Figure5-5). Badly

worn tines will result in a loss of tilling

depth and reducedeffectiveness when

chopping up and turning under organic

matter. UseFigure5-5 asa guideto

when thetines should be replaced.

ModerateWear

Replace

Figure5-5: Checkingtinesforwear.

B. Removinga SingleTine:

1. Removethe two screws and nuts that

attacha single tine to the tine holder

(Figure5-6). If needed,use penetrating

oil to helpfree the nuts.

2. When installing a single tine, besure

to position it so that its cutting edge will

enterthe soil first as the tiller moves

forward.

C. Removinga TineAssembly:

1. If removing both tine assemblies, mark

them "left" and "right" beforeremoval.

Doingso will help ensurethat the assem-

bliesare reinstalled onthe correct sides

of the tiller.

2. Removethe screw and Iocknut that

securethe tine assembly to the tine shaft

(Photo5-7). Pull the tine assembly off

the shaft (if necessary,usea rubber

malletto tap the tine assembly outward).

3. Beforereinstalling the tine assembly,

inspectthetine shaft for rust, rough

spots or burrs andfile or sand as needed.

Apply athin coat of greaseto the shaft.

4. Installeach tine assembly sothat the

cutting edge of the tines will enter the

soil first when the tiller moves forward.

Securethe tine assembly to the tine shaft

usingthe screw and Iocknut previously

removed. Tighten securely.