5 Maintenance

Before inspecting, cleaning or

servicing the machine, shut off engine,

wait for all moving parts to come to a

complete stop, disconnect spark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failure to follow these instructionscan

resultin seriouspersonalinjury or prop-

ertydamage.

MAINTENANCESCHEDULE

PROCEDURE NOTES

Checkmotor oil level 2, 3

Cleanengine 2, 7

Checkdrive belttension 1, 4

Checknuts and bolts 1, 4

Changemotor oil 1, 4, 6

Lubricate tiller 4

Service foam pre-cleaner airfilter 7

(if soequipped)

Service paper air filter (if soequipped) 7

Checkgear oil levelin transmission 1, 5

Checktines for wear 5

Checkair pressure intires 5

Service spark plug 7

NOTES

1- After first 2 hours of break-in operation.

2 - Beforeeach use.

3 - Every5 operating hours.

4 - Every 10operating hours.

5 - Every30 operating hours.

6 - More frequently in dusty ordirty conditions.

7 - SeeEngine Owner'sManual for service

recommendations.

6 - Whichevertime interval occurs first.

TILLERLUBRICATION

D

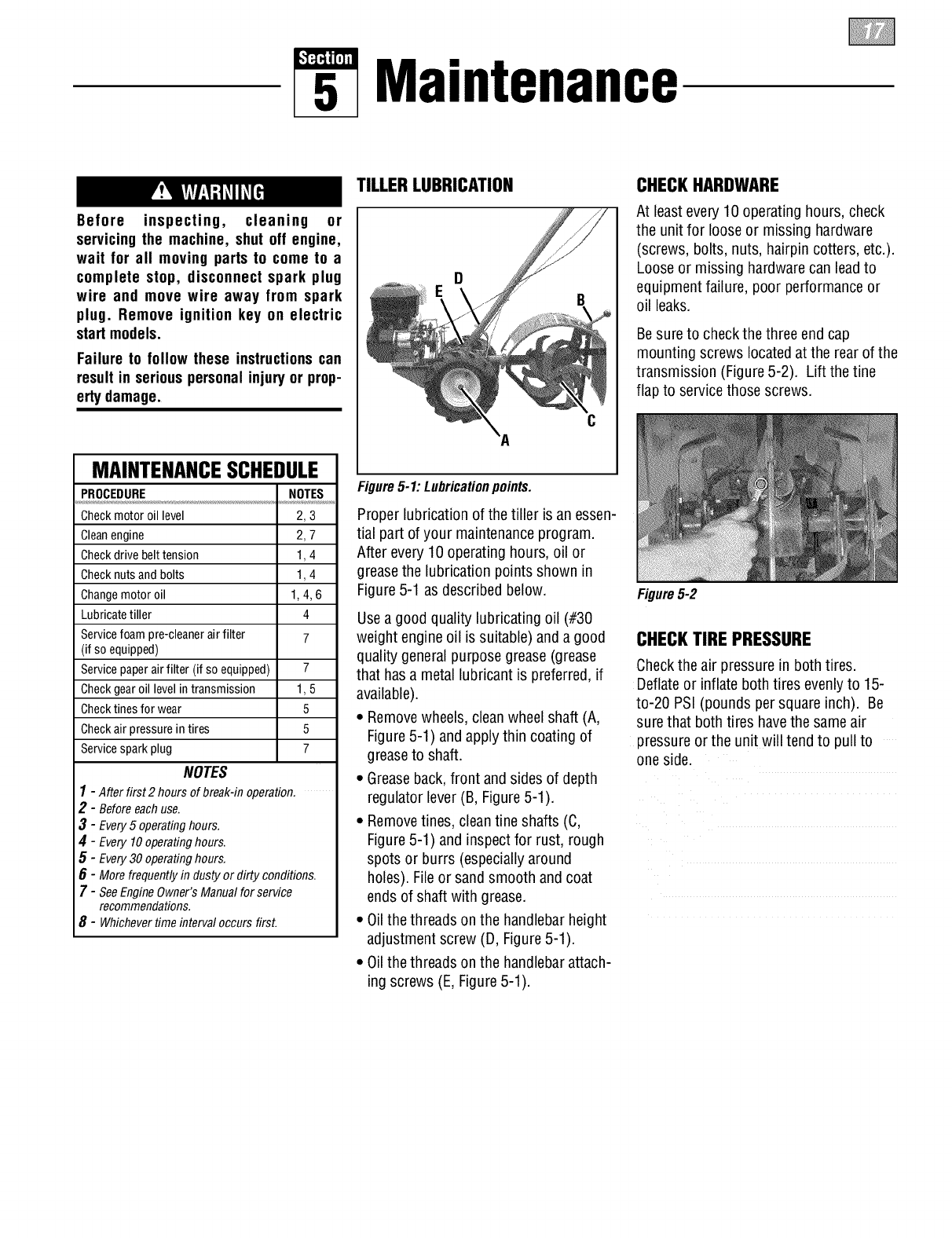

Figure5-1: Lubricationpoints.

Proper lubrication of thetiller isan essen-

tial part ofyour maintenanceprogram.

After every 10 operating hours, oil or

greasethe lubrication points shown in

Figure5-1 as described below.

Usea good quality lubricating oil (#30

weight engine oil is suitable) anda good

quality general purpose grease (grease

that hasa metallubricant is preferred, if

available).

• Removewheels,cleanwheel shaft (A,

Figure5-1) andapply thin coating of

greaseto shaft.

• Greaseback,front and sides of depth

regulator lever(B, Figure5-1).

• Removetines, cleantine shafts (C,

Figure5-1) and inspectfor rust, rough

spots or burrs (especiallyaround

holes). Fileor sand smooth and coat

endsof shaft with grease.

• Oilthe threads onthe handlebarheight

adjustment screw (D, Figure5-1).

• Oilthe threads onthe handlebarattach-

ing screws (E,Figure5-1).

CHECKHARDWARE

At least every 10 operating hours, check

the unit for loose or missing hardware

(screws, bolts, nuts, hairpin cotters, etc.).

Looseor missing hardwarecan leadto

equipment failure, poor performanceor

oil leaks.

Besureto checkthe three end cap

mounting screws locatedat the rear of the

transmission (Figure5-2). Lift the tine

flap to servicethose screws.

Figure5-2

CHECKTIRE PRESSURE

Checkthe air pressure in bothtires.

Deflateor inflate bothtires evenlyto 15-

to-20 PSI (pounds per square inch). Be

sure that bothtires havethe sameair

pressureor the unit will tendto pull to

one side.