ENGINE

AND

SNOWTHROWER

MAINTENANCE

7.

Slowly unscrew the drain plug. Allow the oil

to

run

down the cardboard and into the container.

8.

After the oil has drained, reinstall the drain plug

and very securely tighten

it.

9.

Add clean oil

to

the engine. See "Checking

Engine Oil Level and Adding Oil

to

Engine".

Engine

Ignition

System

The snowthrower engine has

an

electronic ignition

system. This system eliminates the traditional set of

points and condensor. The electronic ignition system

also eliminates the yearly tune-up. The only sched-

uled maintenance you need to perform

on

the

engine's ignition system concerns the spark plug

(which

is

discussed next).

Spark

Plug

Yearly,

or every

100

hours of operation, remove the

engine's spark plug, clean it, and inspect it. Clean

the spark plug by scraping it (don't wire brush it or

sand blast it). Replace the spark plug with a new one

if its electodes were pitted or burned, or if its por-

celain was cracked.

Before installing the spark plug, set its electrode

gap

at

0.030

inch.

COMPLIANCE WITH

RADIO INTERFERENCE

REGULATIONS CERTI-

FIED. REPLACE SPARK

PLUG WITH RESISTOR

.030 (.8

mm)

SPARK PLUG.

FEELER GAUGE

Figure 5-3

Carburetor

Adjustment

Your carburetor has been set for proper operation.

If you believe that it has come out of adjustment,

please refer

to

the engine owner's manual for the

correct carburetor adjustment procedure.

SNOWTHROWER

MAINTENANCE

Lubrication

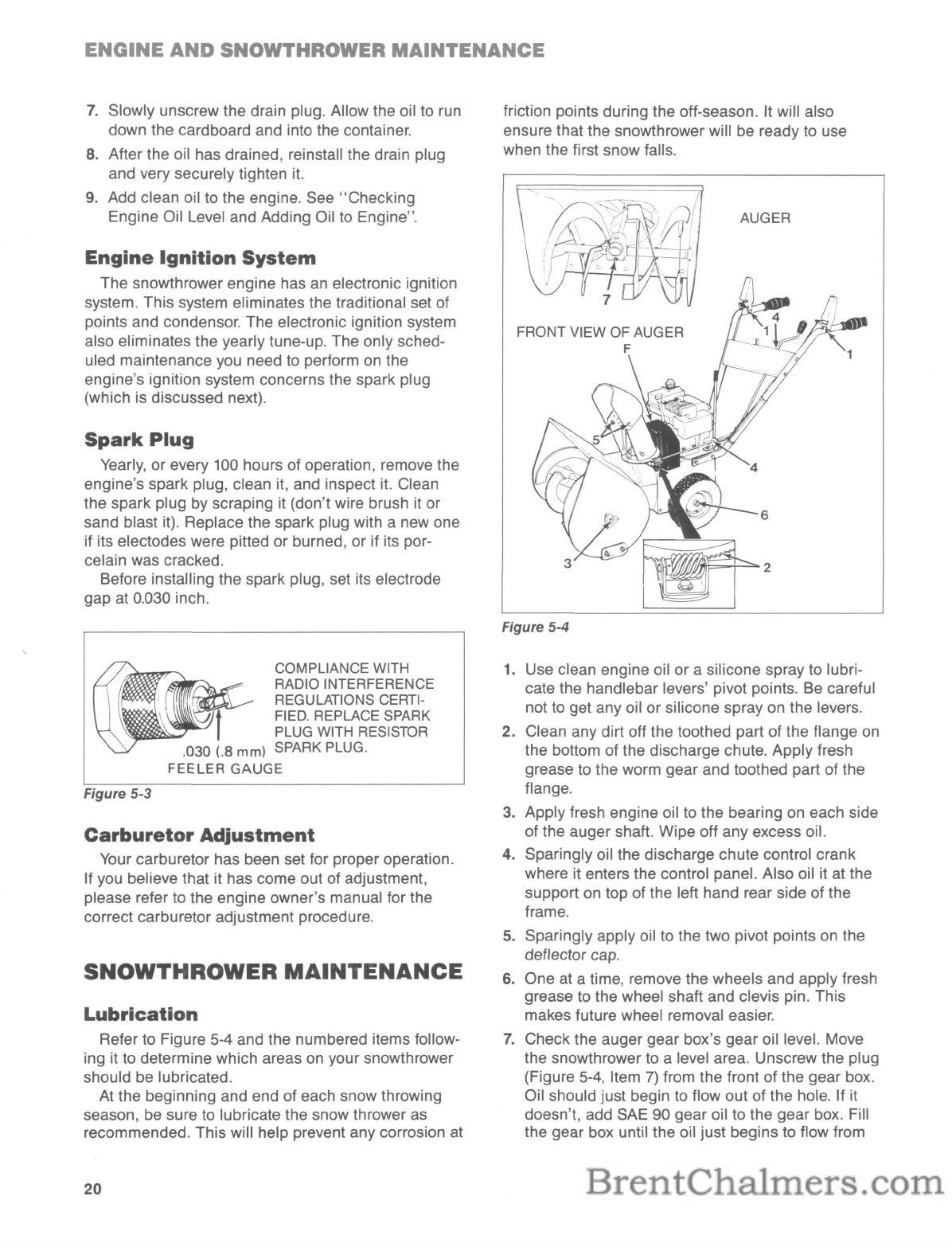

Refer

to

Figure 5-4 and the numbered items follow-

ing it

to

determine which areas

on

your snowthrower

should

be

lubricated.

At

the beginning and end of each snow throwing

season,

be

sure

to

lubricate the snow thrower

as

recommended. This will help prevent any corrosion at

20

friction points during the off-season. It will also

ensure that the snowthrower will be ready

to

use

when the first snow falls.

AUGER

FRONT VIEW OF AUGER

F

Figure 5-4

1.

Use clean engine oil or a silicone spray

to

lubri-

cate the handlebar levers' pivot points.

Be

careful

not

to

get any oil or silicone spray

on

the levers.

2. Clean any dirt off the toothed part of the flange

on

the bottom of the discharge chute. Apply fresh

grease

to

the worm gear and toothed part of the

flange.

3.

Apply fresh engine oil

to

the bearing

on

each side

of the auger shaft. Wipe off any excess oil.

4.

Sparingly oil the discharge chute control crank

where it enters the control panel. Also oil it at the

support

on

top of the left hand rear side of the

frame.

5.

Sparingly apply oil to the two pivot points

on

the

deflector cap.

6.

One

at

a time, remove the wheels and apply fresh

grease

to

the wheel shaft and clevis pin. This

makes future wheel removal easier.

7.

Check the auger gear box's gear oil level. Move

the snowthrower

to

a level area. Unscrew the plug

(Figure

5-4,

Item

7)

from the front of the gear box.

Oil should just begin to flow out of the hole. If it

doesn't, add SAE 90 gear oil to the gear box. Fill

the gear box until the oil just begins to flow from