19

The spring length should now measure

9/16" – 11/16" (14–17mm) longer than the

measurement taken in Step 4. If it does

not, loosen the jam nut (AM, Figure 5-8)

and turn the adjuster (AN) to increase or

decrease the length of the spring. Hold

the adjuster and tighten the jam nut (AM)

when the correct spring length is ob-

tained. Re-check the measurements and

adjust if needed.

NOTE: 1-1/4 turns of the adjuster equals

1/16" (1.5mm) of spring extension.

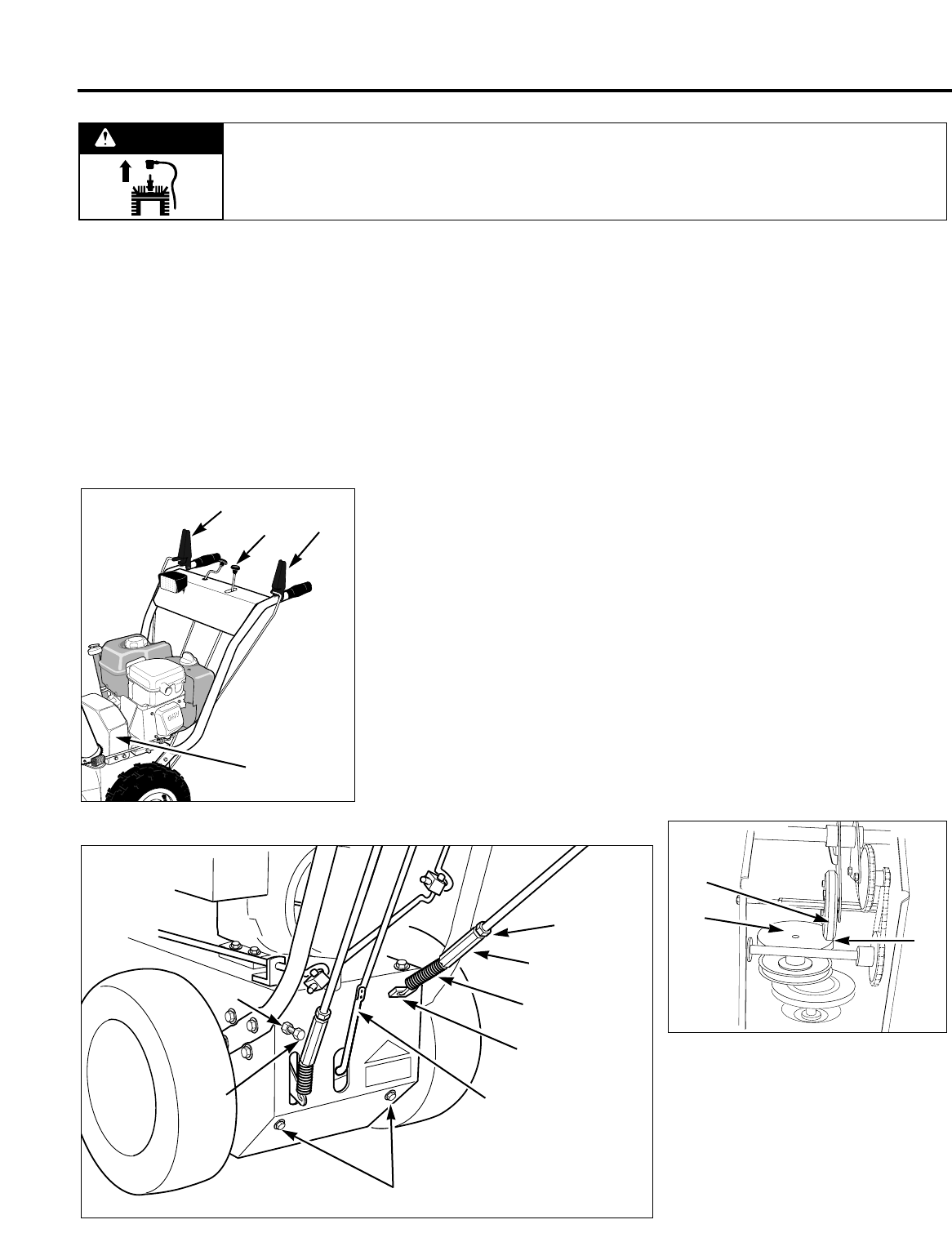

GEAR SHIFT ROD ADJUSTMENT

1. With the engine stopped and the spark

plug wire disconnected, move the gear

shift lever (AU, Figure 5-7) to position

No. 5. Remove the hairpin cotter and

the flat washer from the pivot block (N,

Figure 5-10). Disconnect the pivot

block (N) from the gear shift lever plate

(AV, Figure 5-10).

2. Pull the gear shift control rod (AA,

Figure 5-8) down completely.

3. While holding the gear shift control rod

(AA, Figure 5-8) down, loosen the jam

nut (ZZ, Figure 5-10) and thread the

pivot block (N) up or down as needed

so it fits into the hole in the gear shift

lever plate (AV, Figure 5-10).

4. Reinstall the pivot block (N, Figure 5-

10) into the gear shift control lever hole

and secure with the washer and hairpin

cotter. Secure the jam nut (ZZ, Figure

5-10) against the pivot block (N).

5. Move the gear shift control lever (AU,

Figure 5-7) through the full range of

travel. Check for binding. Refer to the

Drive Disc Clearance Adjustment

instructions, if needed.

DRIVE DISC CLEARANCE

ADJUSTMENT

If the gear shift rod lever does not move

freely through all the gear positions, ad-

just clearance (AY, Figure 5-9) as follows:

1. With the engine stopped and the spark

plug wire disconnected, loosen jam nut

(AW, Figure 5-8). Rotate adjusting

screw (AX) until rubber drive wheel (T,

Figure 5-9) contacts metal drive disc

(U).

2. Turn the rubber drive wheel (T, Figure

5-9) and the metal drive disc (U) to

find the point of minimum clearance

(AY). (This is where both the drive

wheel [T] and metal disc [U] are

touching.)

3. Adjust the discs at the point of mini-

mum clearance. Loosen adjusting

screw (AX, Figure 5-8) 1/2 turn.

Secure the adjusting screw (AX) in

place, while tightening the jam nut

(AW).

4. Check the clearance (AY, Figure 5-9)

by moving gear shift lever (AU, Figure

5-7) through all positions. Repeat

Step 3 as necessary.

BRAKE ARM ADJUSTMENT

The brake arm adjustment is set at the

factory to 1/16 - 1/8" for proper belt/brake

clearance. Due to wear, this may need

adjustment.

Section 5: Maintenance

Figure 5-7

AB

AL

Figure 5-8

Q

AK

AJ

AA

AN

AM

AX

AW

AU

AP

Figure 5-9

AY

T

U

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to

a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING