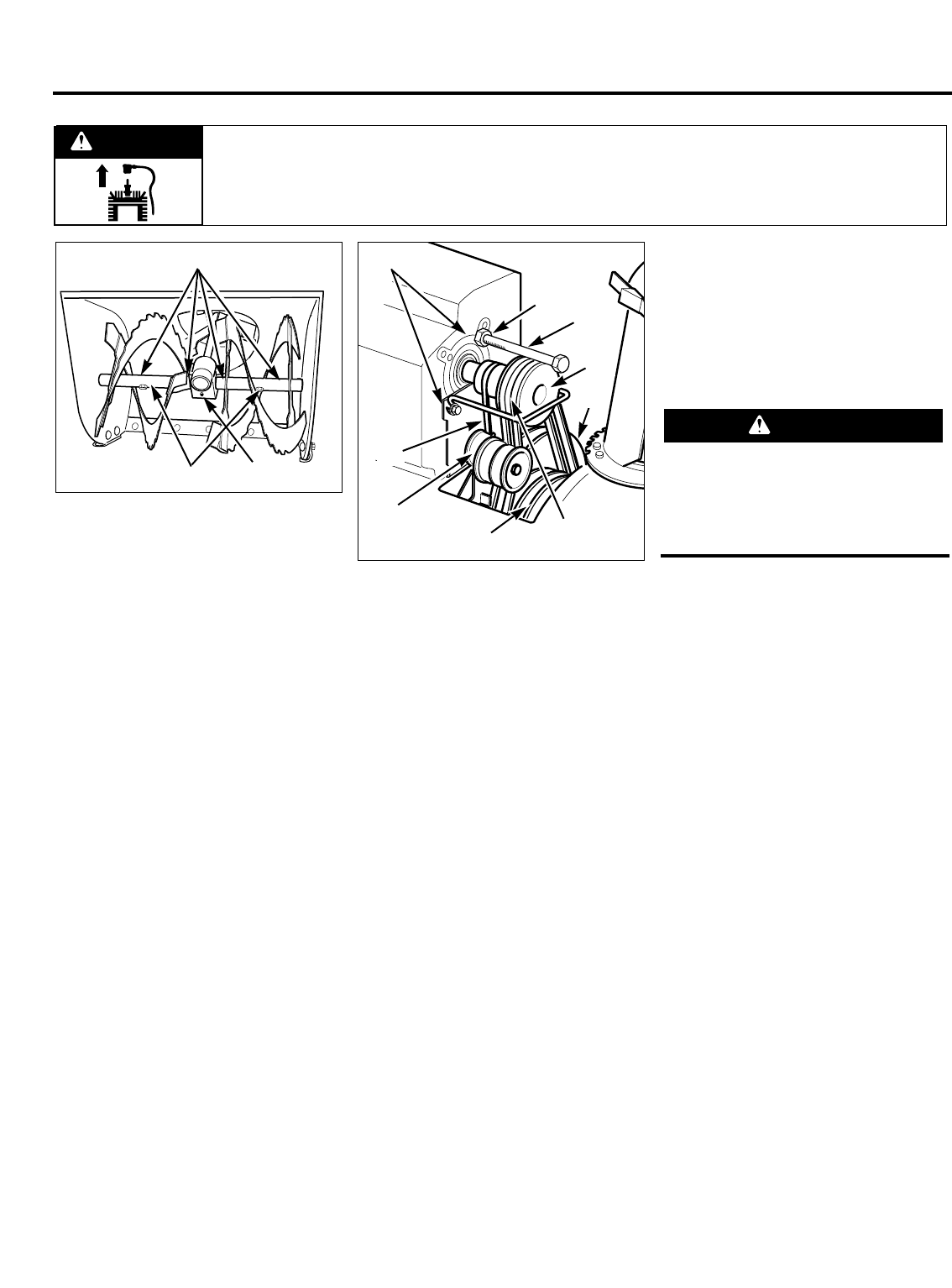

AUGER DRIVE BELT AND WHEEL

DRIVE BELT REPLACEMENT

NOTE: The auger drive belt (there is one

auger drive belt on the 9.5HP model and

two auger drive belts on the 11HP model)

must be removed before removing the

wheel drive belt. The illustration (Figure 5-

6) shows two auger drive belts (AD), ig-

nore the second belt if the unit is not so

equipped.

Removal

1. With the engine stopped and the spark

plug wire disconnected, remove the

screws and washers (AB, Figure 5-1)

and remove the belt cover from the

unit.

2. Remove the two screws, flat washers

and lockwashers securing belt guide

(AC, Figure 5-6) to the engine.

Remove the belt guide.

3. Loosen jam nut (BA, Figure 5-6) and

remove bolt (BB).

4. Release tension on the idler (AF,

Figure 5-6). Remove the auger drive

belt(s) (AD) from the auger drive pul-

ley (AE).

5. Remove the auger drive belt(s) from

the lower drive pulley (AO, Figure 5-9)

and remove belt(s) from unit. NOTE: If

you are not replacing the wheel drive

belt (AG), then proceed to Installation.

6. Remove wheel drive belt (AG, Figure

5-6) from lower drive pulley (AH).

Squeeze wheel drive control lever

against handlebar (X, Figure 5-1) to in-

crease gap between lower pulleys as

needed.

7. Remove the wheel drive belt from unit.

Installation

1. Position wheel drive belt (AG, Figure

5-6) into lower drive pulley (AH) clos-

est to the engine.

2. Place the belt into the groove closest

to the engine of the engine pulley (AE).

3. Position auger drive belt(s) (AD, Figure

5-6) down through gap. Position the

belt(s) into the lower drive pulley (AO).

4. Position the auger drive belt(s) (AD,

Figure 5-6) into engine pulley (AE).

5. Position belt guide (AC, Figure 5-6)

back on engine and secure with two

screws and washers removed earlier.

6. Reinstall bolt (BB, Figure 5-6), leaving

1/16" (1.5mm) clearance between un-

derside of bolt head and front edge of

pulley (AE). Tighten jam nut (BA)

against engine crankcase.

7. If the wheel drive belt has been re-

placed, then perform the wheel drive

disc adjustment (see Wheel Drive Disc

Adjustment ).

8. If the auger drive belt(s) have been re-

placed, then perform the Auger Drive

Belt Adjustment as described in this

section.

9. Reinstall the belt cover.

SHEAR BOLTS

Special shear bolts (L, Figure 5-5) secure

the augers to the auger shaft and are de-

signed to break (shear) if the auger jams.

This prevents damage to other, more vital

parts. Inspect shear bolts before each use

and replace them if they are worn or bro-

ken. Torque shear bolts to 11 ft-lbs

(15 Nm).

AUGER DRIVE BELT(S)

ADJUSTMENT

Due to wear, the auger drive belt(s) may

begin to slip when the auger drive lever is

engaged. To adjust the auger drive belt(s):

1. Perform the brake arm adjustment as

described in this section. Leave the

spark plug wire disconnected while per-

forming this adjustment.

2. If assembling a new unit, raise the

wheel drive control lever (AP, Figure

5-7) and the auger drive control lever

(AL).

3. Pull the auger drive control arm (AJ,

Figure 5-8) down completely.

4. Measure and note distance between

coiled ends of spring (AK, Figure 5-8).

5. Squeeze auger drive control lever (AL,

Figure 5-7) against handlebar. Measure

between the coiled ends of the

stretched spring (AK, Figure 5-8), mak-

ing sure you measure between the

same coils used in step 4.

Section 5: Maintenance

Figure 5-5

Figure 5-6

L

AC

AD

BB

BA

AE

AH

AG

AF

AO

N

M

CAUTION

Using anything but original equipment

shear bolts could result in damage to

the unit. Use factory-specified auger

shaft shear bolts when replacing shear

bolts.

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to

a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

18