Reelmaster 2300–D/2600–DHydraulic System Page 4 – 44

Wheel Motor

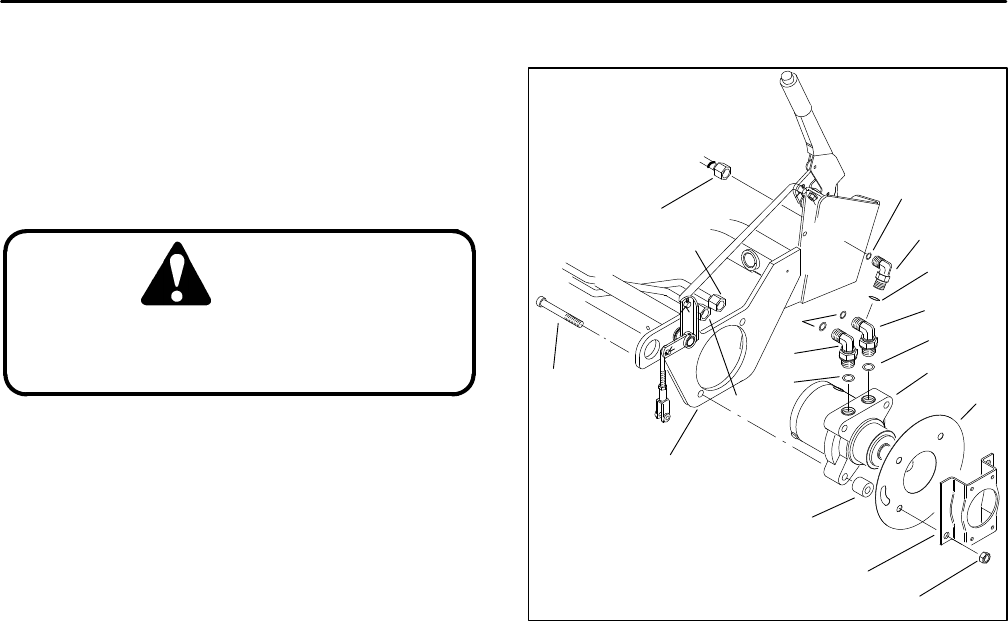

Front Wheel Removal (Fig. 30)

1. Before removing any parts from the hydraulic sys-

tem, park the machine on a level surface, engage the

parking brake, lower the cutting units and stop the en-

gine. Remove the key from the ignition switch.

CAUTION

Operate all hydraulic controls to relieve

system pressure and avoid injury from

pressurized hydraulic oil.

2. Remove wheel and brake assembly from unit (see

Repair section of Chapter 6 – Wheels and Brakes).

3. Clean wheel motor (1) and hydraulic connections.

Label all tube hose connections for reassembly pur-

poses. Put caps or plugs on any hydraulic lines or fittings

left open or exposed.

4. Disconnect tube connections (2 and 3) from hydrau-

lic fittings (5 and 6). On the left–hand wheel motor, also

disconnect hose connection (4) from hydraulic fitting (7).

Allow hydraulic oil to drain from tubes and hose into a

suitable container.

5. Support wheel motor (1). Remove four cap screws

(10) and lock nuts (11) from support frame (12). Remove

brake bracket (13), grass shield (14), and spacers (15).

Pull wheel motor from the support frame.

6. Remove hydraulic fittings (5 and 6) and O–ring from

the wheel motor (1). On the left–hand wheel motor, also

remove hydraulic fitting (7) from the wheel motor.

Front Wheel Installation (Fig. 30)

1. Place and support wheel motor (1) into the support

frame (12). Insert four cap screws (10) through the sup-

port frame and wheel motor.

2. Slide spacers (15), grass shield (14), and brake

bracket (13) onto the cap screws (10) and wheel motor

(1). Tighten lock nuts (11) onto cap screws.

3. Install hydraulic fittings (5 and 6) onto the wheel mo-

tor (1). On the left–hand wheel motor, also install hy-

draulic fitting (7) onto the wheel motor. Tighten hydraulic

fittings.

1. Wheel motor

2. Tube connection

3. Tube connection

4. Hose connection

5. Hydraulic fitting

6. Hydraulic fitting

7. Hydraulic fitting

8. O–ring

9. O–ring

10. Cap screw

11. Lock nut

12. Support frame

13. Brake bracket

14. Grass shield

15. Spacer

16. O–ring

17. O–ring

Figure 30

1

4

10

2

3

16

8

9 (LH)

7 (LH)

17 (LH)

6

16

14

15

13

11

12

5

4. Install tube connections (2 and 3) to hydraulic fit-

tings (5 and 6). On the left–hand motor, also ins hose

connection (4) to hydraulic fitting (7). Tighten connec-

tions.

5. Install wheel and brake to unit (see Repair section

of Chapter 6 – Wheels and Brakes).