Reelmaster 2300–D/2600–D Hydraulic SystemPage 4 – 79

Flushing the Hydraulic System

IMPORTANT: Flush the hydraulic system any time

there is a severe component failure or the system is

contaminated (oil appears milky or black or con-

tains metal particles).

IMPORTANT: Flush hydraulic system when chang-

Ing from petroleum base hydraulic fluid, such as

Mobil 424, to biodegradable fluid, such as Mobil

EAL 224H. Operate machine under normal operat-

ing conditions for at least four (4) hours before

draining.

1. Park machine on a level surface. Lower cutting

units, stop engine, engage parking brake and remove

key from ignition switch.

2. Clean area around filter mounting area. Remove fil-

ter and drain reservoir into a suitable container. Drain

hydraulic system, Make sure lift cylinders, hoses, and

tube lines are drained while the system is warm. Discard

filter.

3. Inspect and clean reservoir (see Inspecting Reser-

voir Parts).

4. Make sure filter mounting surface is clean. Apply

hydraulic oil to gasket on the new filter. Screw filter on

until gasket contacts mounting plate, then tighten filter

half a turn.

Note: Use biodegradable fluid, such as Mobil EAL

224H, for this step if you are changing to this type of fluid.

Use only hydraulic fluids specified in Checking Hydrau-

lic System Fluid (see General section of this chapter).

Other fluids could cause system damage.

5. Fill hydraulic reservoir.

6. Disconnect electrical connector to the fuel stop so-

lenoid to prevent engine from starting.

7. Turn ignition key switch; engage starter for ten (10)

seconds to the prime pump. Repeat this step again.

8. Connect electrical connector to the fuel stop sole-

noid.

9. Start engine and let it idle at low speed for a mini-

mum of two (2) minutes.

10. Increase engine speed to high idle for minimum of

one (1) minute under no load.

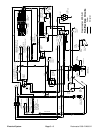

1. Hydraulic reservoir cap

2. Sight gauge

Figure 68

1

2

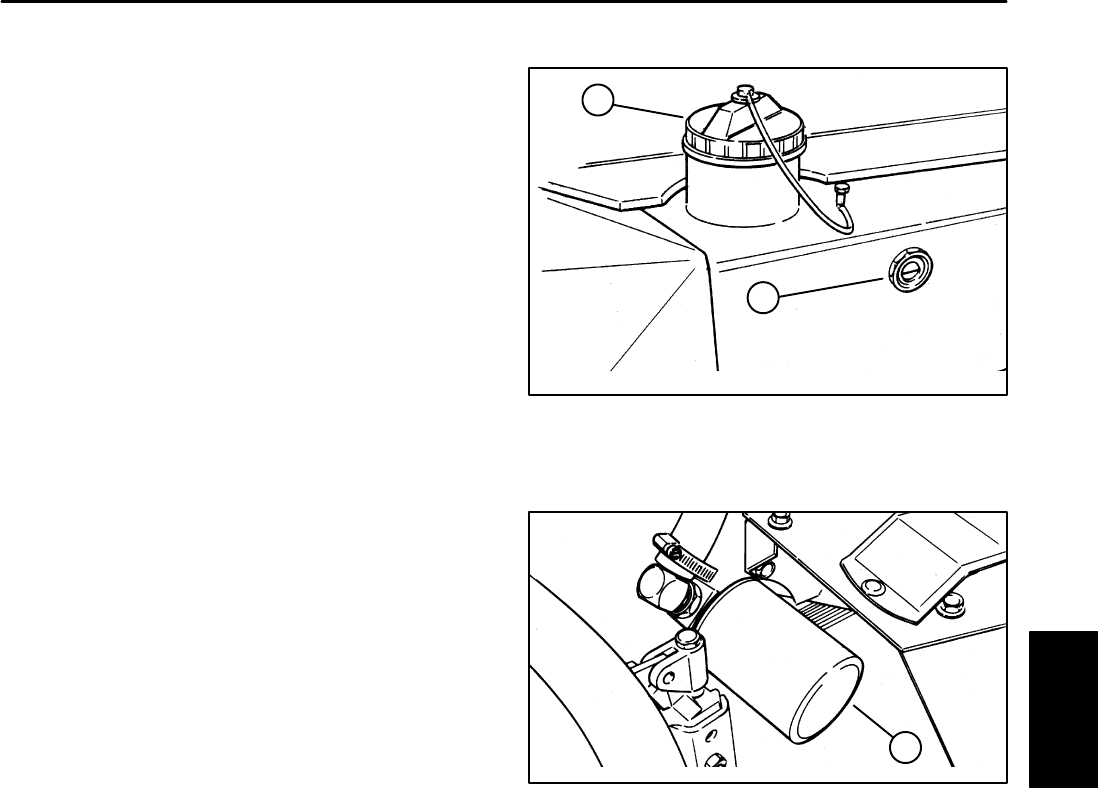

1. Hydraulic filter

Figure 69

1

11. Raise and lower cutting units several times.

12. Shut off engine and check for hydraulic oil leaks.

Check oil level in hydraulic reservoir and add correct oil

if necessary.

13. Operate the machine for two (2) hours under normal

operating conditions.

14. Check condition of hydraulic oil. If the flushing fluid

shows any signs of contamination, or if you are changing

to biodegradable fluid, repeat steps 1 through 14 again.

15. Assume normal operation and follow recom-

mended maintenance intervals.

Hydraulic

System