Reelmaster 2300–D/2600–D

Page 5 – 32

Electrical System

Installation

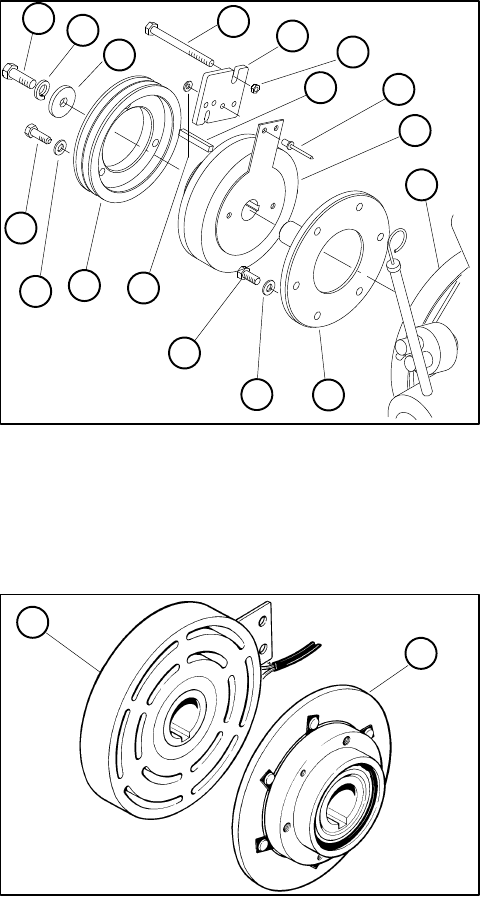

1. When installing an new clutch, remove the wire

bracket from the old clutch and install it with the flat

washers and new pop rivets on the new clutch. Run the

wires through the bracket and tie wrap to them to the

bracket as on the original clutch. Make sure wires are

tight against the clutch wire bracket or they will

catch in the spindle bolts (Fig. 30).

2. Make sure the spindle is free of dirt and rust. Insert

the capscrews with flat washers through the spindle

base from the shaft side (Fig. 30).

3. Apply never seize to the spindle shaft and keyway.

Slide the clutch rotor (Fig. 31) onto the spindle shaft with

the bracket side towards the spindle base (Fig. 30).

Make sure that the capscrews with the flat washers stay

in the spindle holes.

4. Apply never seize to the key. Insert the key into the

keyway. Slide the armature (Fig. 31) onto the shaft and

key (Fig. 30).

5. Place the the capscrews through the lock washers

and secure the pulley to the clutch. Place the lock wash-

er and large flat washer onto the capscrew and secure

them to the shaft; torque from 40 to 50 ft–lb (Fig. 30).

6. Place the clutch and spindle up to the flywheel.

Screw one of the capscrews into the flywheel to support

the spindle during alignment. Secure all the capscrews

while pushing the spindle into the flywheel; tighten in a

crisscross pattern (Fig. 30).

7. Align the wire bracket with the long capscrew into

their original position. Secure the long capscrew and

jam nut through the bracket into the engine block (Fig.

30).

8. Run the electrical connector through the R–bracket

with the cable harness and reconnect. Make sure the

wires do not make contact with moving parts of the

clutch and that the R–bracket capscrew is tight.

9. Tilt the pump mount and install the belt to the clutch

and pump pulleys. Align the adjusting yoke with the

pump mount holes and secure with the clevis and cotter

pins (Fig. 28). Adjust the belt (see Adjustments section

of Chapter 4 – Hydraulic System).

10. Secure the U–bracket support to the frame using

the carriage bolts and nuts. Place the two capscrews

through the flat washers and grommets; apply loctite to

capscrew threads. Secure the hydraulic tank to the U–

bracket support with the two capscrews (Fig. 29).

11. Attach the dampener to the traction pedal and U–

bracket support (Fig. 27). Adjust the traction pedal (see

Adjustments section of Chapter 4 – Hydraulic System).

12. Replace and secure panels to the unit. Reconnect

the fuel solenoid.

1. Long capscrew

2. Jam nut

3. Clutch spindle

4. Flywheel

5. Capscrew

6. Flat washer

7. Clutch

8. Capscrew

9. Lock washer

10. Pulley

11. Capscrew

12. Lock washer

13. Flat washer

14. Key

15. Wire bracket

16. Pop rivet

17. Flat washer

Figure 30

9

8

11

12

13

1

2

16

7

5

6

3

17

14

4

10

15

1. Rotor 2. Armature

Figure 31

2

1