MAINTENANCE

Maintenance Section 5-8

© 2006 Alamo Group Inc.

MAINTENANCE

FLX15/10 04/06

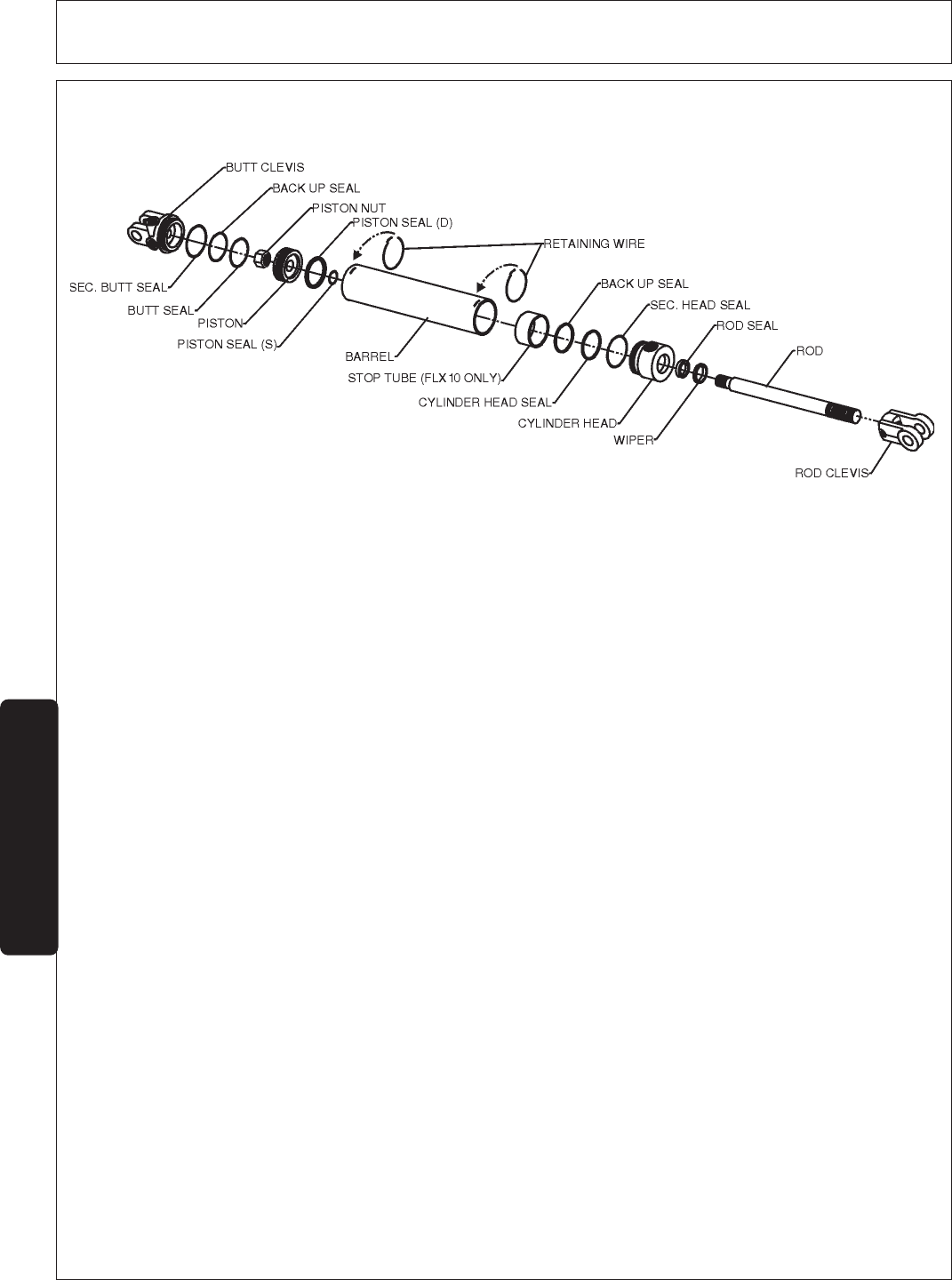

RAMLOK DISASSEMBLY PROCEDURE

1. Replacement cylinder head and butt seals must be available before beginning disassembly as they

will be damaged during the procedure. The piston seal may also be subject to damage during

disassembly.

2 Secure the cylinder snugly in a vice. Do not over tighten the vice or the barrel will compress.

3. Locate the slots at either end of the barrel. The cylinder head will be removed first.

4. Using a thin blade screwdriver, insert the blade into the end of the slot near the cylinder head and pry

the retaining wire up slightly.

5. With the screwdriver under the wire, rotate the cylinder head to thread the wire out. The cylinder

head can be turned with a pin wrench in the holes provided, with a pipe wrench, or with a strap wrench.

6. Thread the wire completely out of the barrel. Note which hole in the cylinder head that the wire was

inserted in (there are 4 holes in the cylinder head. When reinstalling the cylinder head, the wire must

be inserted in the same hole and the wire must be installed in the opposite rotation from removal (ie. If

the cylinder head was turned clockwise to remove the wire, it must be turned counterclockwise for

installation). This will ensure correct port orientation.

7. With the cylinder head wire completely removed, disassembly can continue. Ensure that the ports

at both ends of the cylinder are open to the atmosphere. Insert a long pin or a bar thru the pin hole on

the shaft mount. Use this bar to fully extend the shaft. A hard pull should dislodge the cylinder head

from the barrel.

8. Continue to pull on the shaft until the o-ring on the cylinder head becomes lodged in the slot in the

barrel. Insert a knife in the slot and cut the o-ring and back up seal. These seals can be threaded out

thru the slot in the barrel.

9. Continue to pull on the shaft. The cylinder head, piston and shaft will pull free from the barrel.