OPERATION

OPERATION

Operation Section 4-15

© 2006 Alamo Group Inc.

FLX15/10 04/06

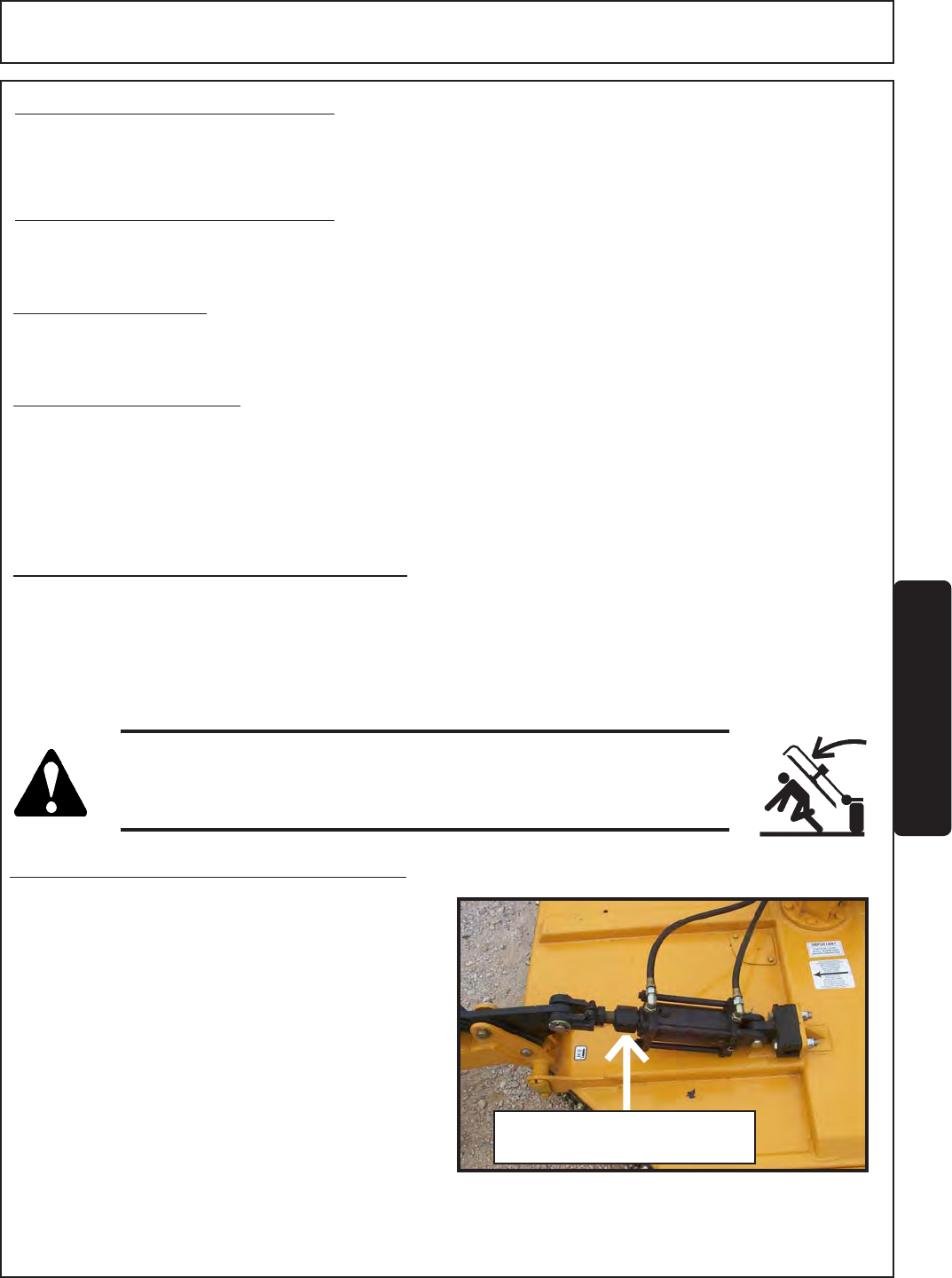

The cut height for the center section is set by extending

or shortening the depth collar located on the center lift

cylinder. Cutting height for the wing cylinders will be

automatically controlled by the hydraulic phasing

system. Depth stops are also provided on the wing

cylinders as back up for fine adjustments.

IMPORTANT: If depth control stops are not set at the

same height as the center cylinder, internal damage

may occur to the phasing cylinders.

The cutter should always be operated in the highest

position that will produce the desired cutting results.

Operating at increased heights will minimize the

chances of blades contacting the ground and

discharging debris.

6.1 SETTING CUTTING HEIGHT

6. SETTING THE MOWER

Properly setting the cutting height is essential for efficient and safe operation. A properly set mower will make a

more uniform cut, distribute clippings more evenly, require minimal tractor work, and follow the contour of uneven

terrain. Note: Avoid very low cutting heights, striking the ground with the blades gives the most damaging shock

loads and will cause damage to the mower and drive. Blades contacting the ground may cause objects to be

thrown out from under the mower deck. Always avoid operating the mower at a height which causes the blades to

contact the ground.

Hydraulic Cylinders must be filled with hydraulic oil before removing the wing transport pins to lower the mower

wings and deck. Hydraulic cylinders and lines are filled by holding the valve control levers in the raised position

until the cylinders fully retract (wing cylinders) and extend (center cylinder). Place control levers in the float

position and repeat process several more times to purge all air from the system. Ensure wings are entirely

supported by the cylinders before removing the transport pins. NEVER drive out pins and NEVER remove

transport pins that have tension on them.

Hydraulic Cylinder Priming

Never work under the Implement, the framework, or any lifted compo-

nent unless the Implement is securely supported or blocked up to

prevent sudden or inadvertent falling which could cause serious injury

or even death. (SG-14)

DANGER!

Hydraulic Cylinder

Depth Collar Adjustment

After connecting the Flex-Arm hydraulic lines to the tractor,and mower hydraulics to the Flex-Arm, support the

hoses with the equipped brackets. Ensure that hoses do not contact the driveline, do not bind while turning, and

do not become pinched or kinked.

Hydraulic Line Support

FLX15 Hydraulic Circuit Requirements

Hoses and breakaways are provided in order to connect to a 15’ rotary cutter with individual single acting wing

circuits. A total of 4 hydraulic circuits are required. Two of the circuits require float positions on the control

valves in order to operate the single acting wing circuits on the rotary cutter.

FLX10 Hydraulic Circuit Requirements

Hoses and breakaways are provided in order to connect to a 10’ rotary cutter with single acting wing circuit. A

total of 3 hydraulic circuits are required. One of the circuits requires a float position on the control valve in order

to operate the single acting wing circuit of the rotary cutter.