MAINTENANCE

Further Troubleshooting

In the event of excessive vibrations check wear on the knives and the cutter-holder discs, check tightness of all bolts

and nuts, check lubrication of the gearbox and of the oil bath unit in the cutter bar.

Excessive vibration cal lead to prolonged noise exposure and affect performance, since mechanical parts are subject

to more stress.

In the event of prolonged vibration contact the service department of RHINO or its dealer.

MAINTENANCE

Storage

To prepare your Disc Mower for storage:

1. Clean the mower of all dirt and debris.

2. Drain the oil from the cutter bar and replace with fresh SAE HD90 lube oil. (See Lubrication Instructions)

3. Store the mower on a clean, dry surface in the down (working) position.

4. Loosen the drive belts or remove the belts and store in a dry place.

5. Lubricate all points and slides before storage; this prevents corrosion.

NOTE: Now would be a good time to replace all damaged parts in preparation for the next cutting season.

NEVER DISCONNECT MOWER FROM TRACTOR WITHOUT CUTTER BAR IN

LOWERED TO (OPERATING) POSITION.

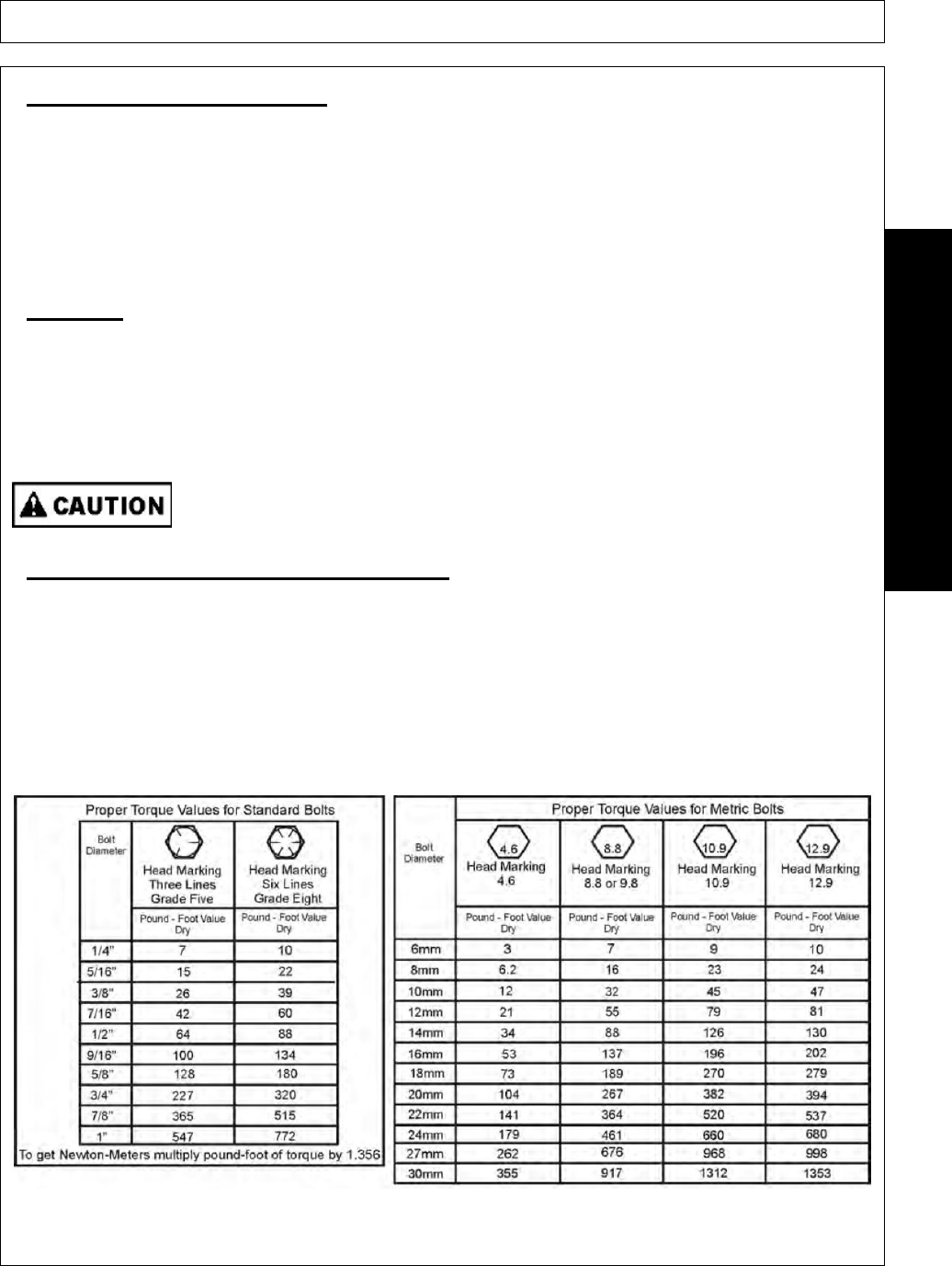

Proper Torque Chart for Fasteners

Because of the severe operating conditions, correct bolt torque is very important. An improperly torqued bolt can be

easily shaken loose or broken by the vibrations. When replacing bolts, always use the same grade of bolt as used

originally. Use this chart as a guide to tightening all bolts. Torque valves listed are for general use only.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL*

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They

do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This

applies to both UNF fine and UNC coarse threads.

AGM 52-62-72-82 10/10

Maintenance Section 5-9

© 2010 Alamo Group Inc.