MAINTENANCE

This section contains recommendations for regular maintenance of the machine, basing on company experience as

well as suggestions by our customers.

These recommendations can be further integrated by contributions from our customers, for which we thank you very

much in advance.

Careful and systematic servicing helps reduce maintenance costs and ensure efficient operation.

If there is any trouble the operator shall stop the machine, identify the trouble and make repairs if necessary.

If you use compressed air or water for cleaning the machine, wear suitable safety glasses or masks and keep people

and animals away. Do not use any inflammable fluids.

During maintenance wear the suitable Protective Devices (safety shoes and gloves) and follow all relevant safety

precautions.

It is recommended to check tightness of all screws and bolts, including those of the knives, every 8 hours of work.

MAINTENANCE

BEFORE PERFORMING INSPECTIONS, MAINTENANCE OR ADJUSTMENTS OF THE

MOWER, STOP THE TRACTOR ENGINE, REMOVE THE KEY, AND SECURE PARKING

BRAKE. WAIT FOR ALL ROTATING MOTION OF THE MOWER TO STOP AND

DISCONNECT THE DRIVELINE SHAFT.

BLOCK THE MOWER AND TRACTOR TO PREVENT MOVEMENT BEFORE

PERFORMING ADJUSTMENTS OR MAINTENANCE.

AFTER MAINTENANCE OR ADJUSTMENTS ARE COMPLETED, REMOVE ALL BLOCKS

AND TOOLS USED IN MAINTENANCE OR ADJUSTMENTS. FAILURE TO CLEAR THE

AREA AROUND THE MOWER BEFORE OPERATION COULD RESULT IN OBJECTS

BEING THROWN TOWARD THE OPERATOR OR BYSTANDERS.

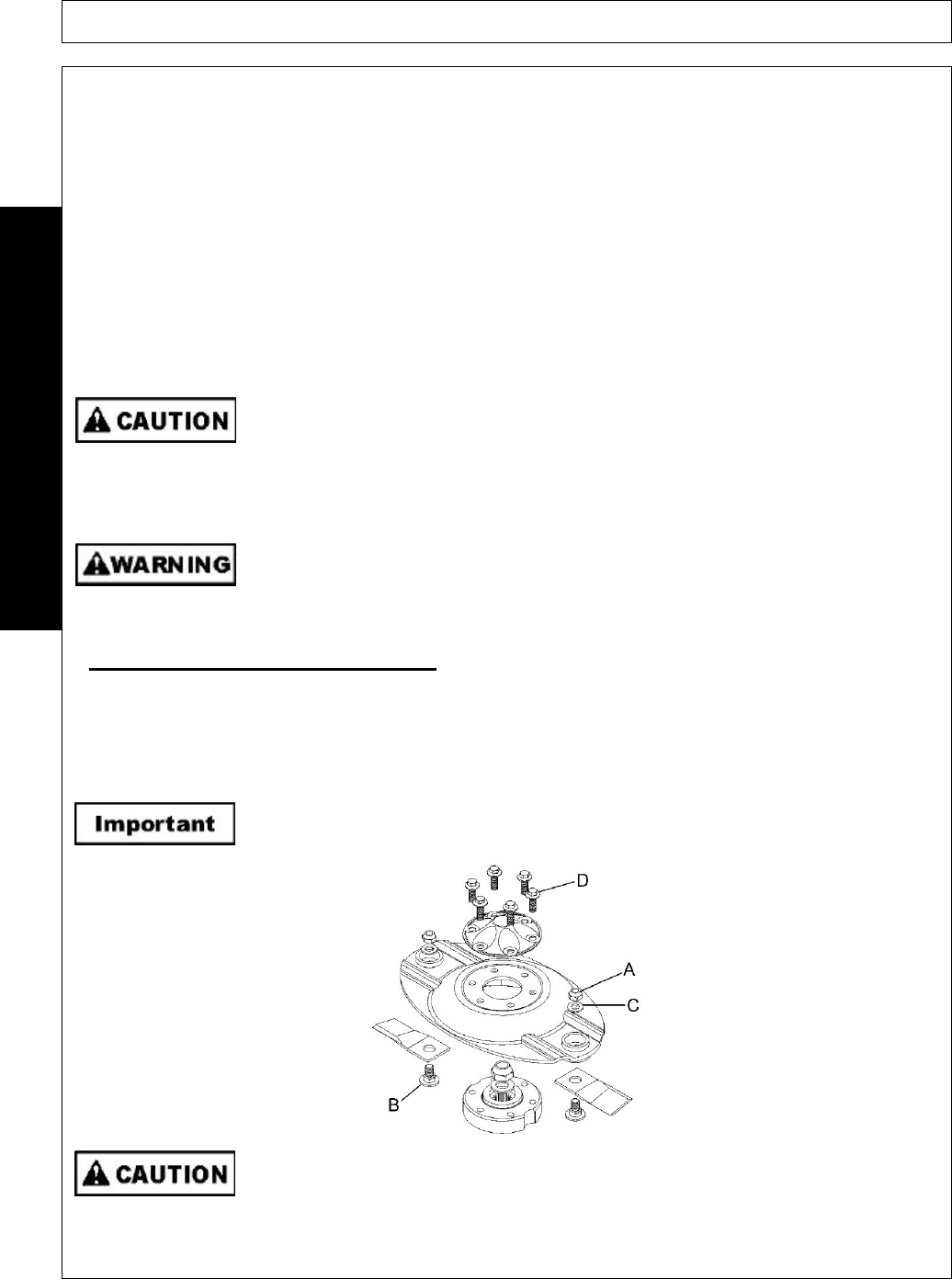

Disk and Blade Maintenance

For longer service file, carefully check discs, blades and bolts daily. When replacements are necessary, use only

Rhino recommended parts. Use of parts not approved by Rhino could void the warranty. Worn, bent or blunt blades

will require more power. To cut efficiently, replace worn or damaged blades as soon as possible. To replace the blade,

remove the Self-Locking Nut (A), Spring Washer (C), remove the Blade Bolt (B). Check the condition of the bolt and

nut. If either are damaged, replace with new parts. The self-locking nut must be threads. Torque the blade bolt to 48

ft./lbs.

During operation, the blades will reach a speed of 3000 RPM. It is very important that the nut

and bolt be in good condition and torque to 48 ft./lbs.

A BENT BLADE CAN SERIOUSLY AFFECT THE OPERATION OF THE MACHINE AND

THROW MORE OBJECTS. REPLACE BENT BLADES AT ONCE! ALWAYS REPLACE

BLADES AND HARDWARE IN PAIRS TO MAINTAIN BALANCE.

AGM 52-62-72-82

10/10

Maintenance Section 5-2

© 2010 Alamo Group Inc.