13

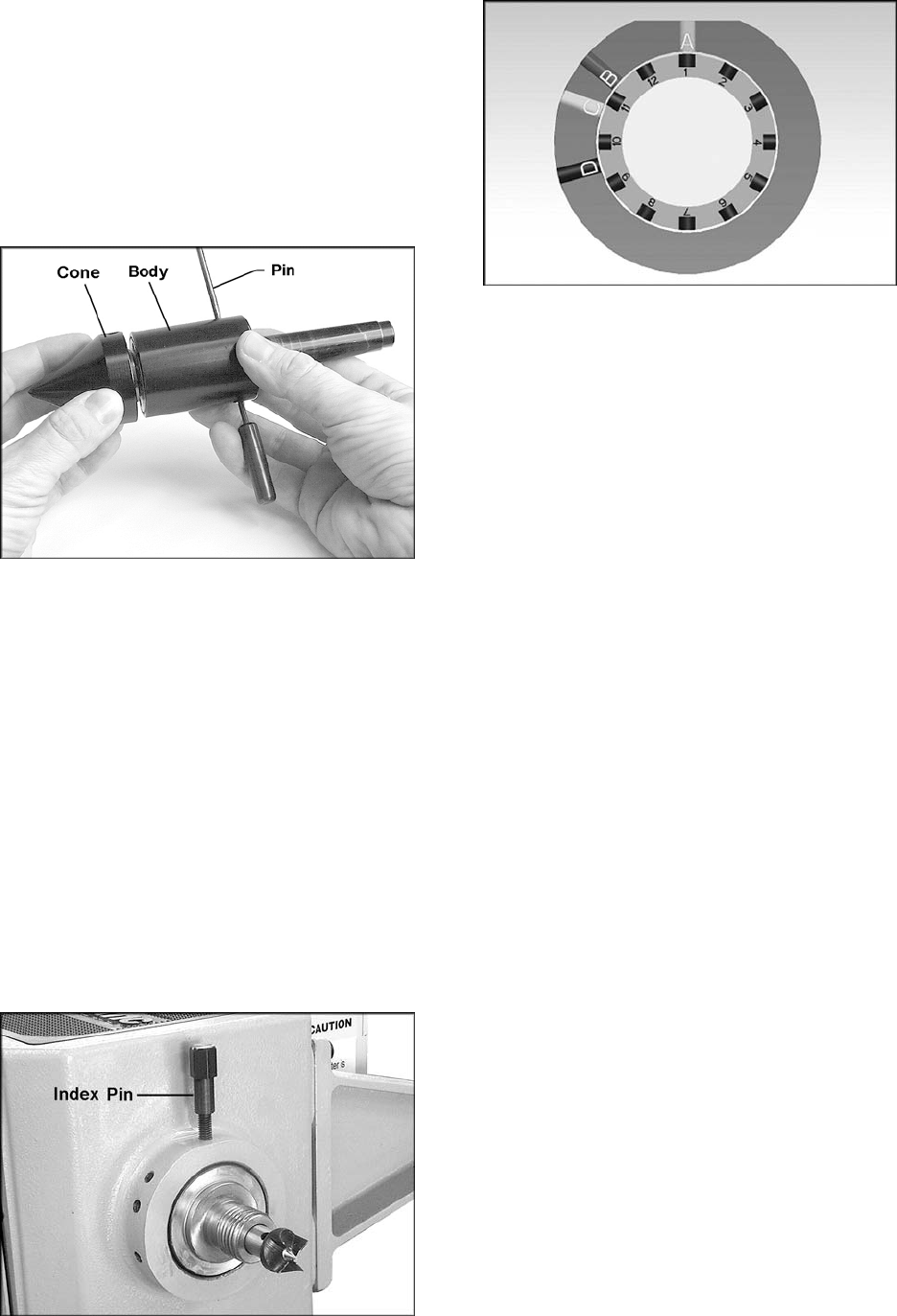

9.5 Live center and cone

The live center cone, shown in Figure 16, screws

clockwise onto the threads of the live center body.

To remove the cone from the live center, first insert

the live center pin through the hole in the live

center body as shown in Figure 16. If the pin will

not insert at first, rotate the cone until the pin can

be inserted. The cone can now be removed by

holding the body stationary while unscrewing the

cone.

Figure 16

9.6 Indexer

The indexer allows you to cut evenly spaced

features in a workpiece while keeping the Lathe

headstock spindle locked; for example, when

cutting flutes on a spindle blank with a router, while

the spindle blank is secured within the Lathe

centers.

There are 12 holes in the spindle collar spaced 30°

apart, and 4 holes in the headstock casting which

accept the index pin (see Figures 17 and 18). The

combination of holes will allow you to mark your

workpiece for evenly spaced features.

1. To use the indexer, thread the index pin

(Figure 17) into one of the four holes until the

index pin engages the spindle and prevents it

from turning. This will be your first indexing

position.

Figure 17

Figure 18

2. Unscrew and remove the index pin, and look

down the hole, carefully counting the number

of holes as you rotate the spindle using the

handwheel. Continue to rotate the spindle until

you reach the hole needed for your second

flute cutting, then re-insert the index pin.

3. Refer to the more detailed instructions and

chart in sect. 13.0 to determine in which holes

to place the index pin relative to the number of

features desired in your workpiece.

IMPORTANT: Remove index pin before turning

on the Lathe!

9.7 Centers: installing/removing

1. Disconnect Lathe from power source.

2. To install a spur center or live center (the spur

center should first be mounted to your

workpiece; see under “Operation” for more

details), clean the tapered end of the center

and the inside of the headstock taper spindle,

then push the center into the headstock

spindle.

3. To remove a spur center or live center, first

remove the workpiece from the Lathe. Insert

the knockout rod (Figure 19) through the hole

in the handwheel and firmly tap the tapered

end of the spur center. The sliding collar on

the knockout rod helps give the necessary

impact without having to use a mallet against

the end of the rod.

IMPORTANT: Hold the center by either placing

your thumb and forefinger on the outside diameter

of the spur center, or wrapping the center with a

rag. The center can be damaged if allowed to fall.